Constant-temperature storage method for synthetic PU resin

A storage method and technology of PU resin, applied in the field of storage tanks, can solve the problems of increasing manufacturers' losses, falling on the ground, damage, etc., and achieve the effect of reducing losses and increasing the support area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

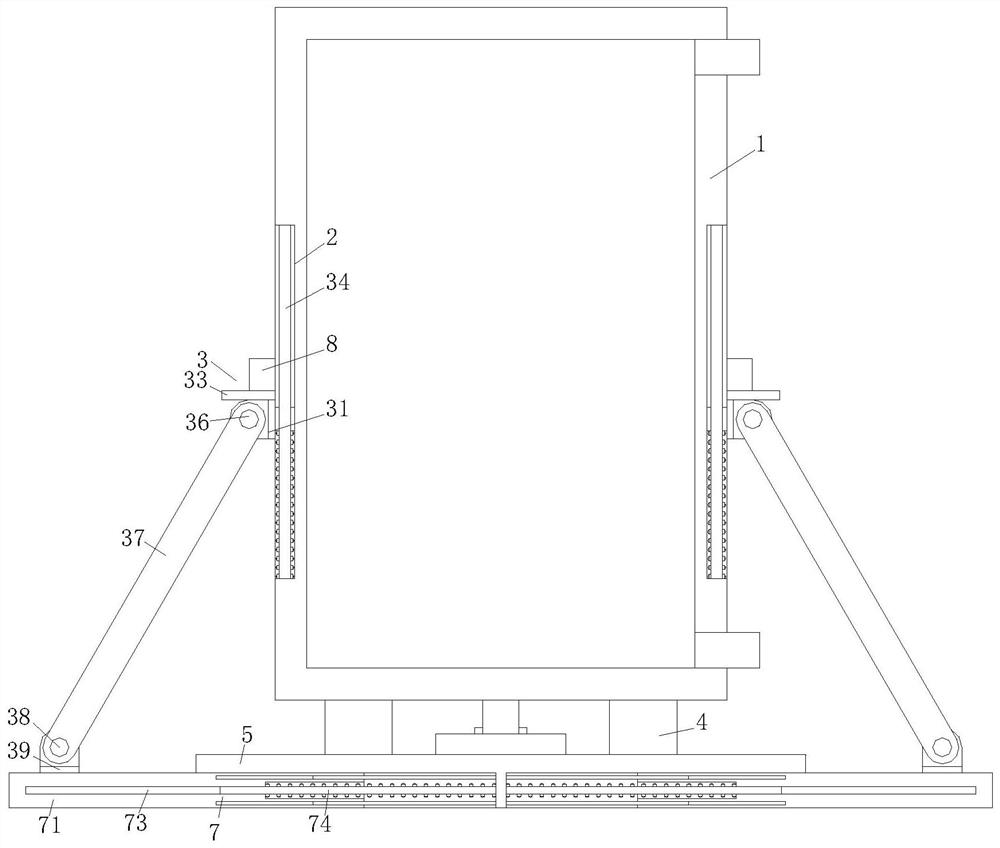

[0031] Such as Figure 1-Figure 8 Shown, a kind of synthetic PU resin constant temperature storage method of the present invention, the method adopts the following steps:

[0032] S1: According to the specific situation, first place the storage tank in the corresponding position, and turn on the power supply, and use the storage tank to store the synthetic PU resin at a constant temperature;

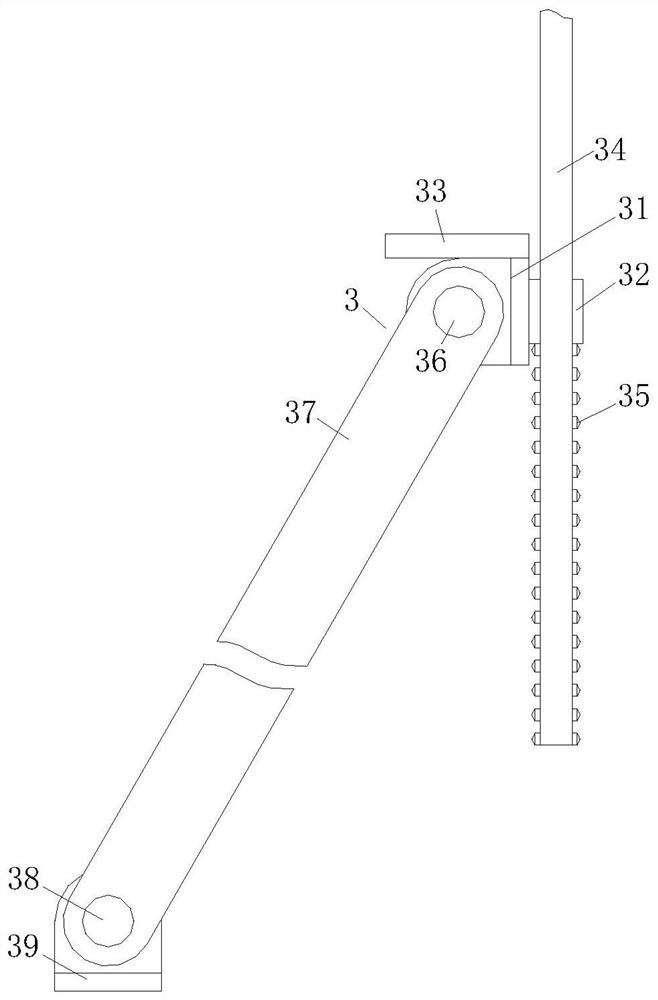

[0033] S2: Start the hydraulic cylinder 82, the hydraulic cylinder 82 lowers the fixed ring 83, and at the same time, the third spring 95 presses the fixed ring 83 downward to reduce the load on the hydraulic cylinder 82, and when the fixed ring 83 descends, the first support 31 is downward Slide and lower the support plate 37, the first support 31 can cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com