A groundwater control method in the construction phase of pba underground excavation subway station

A technology for subway stations and construction phases, applied to artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of water resource saving steel pipe pile connection positioning difficulty, poor reliability, and large surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with drawings and embodiments.

[0045] A groundwater control method in the construction phase of a PBA underground excavation subway station, including the construction steps of the steel pipe pile water-stop curtain are as follows:

[0046] Step 1, prefabricating the first steel pipe pile 1 and the second steel pipe pile 2;

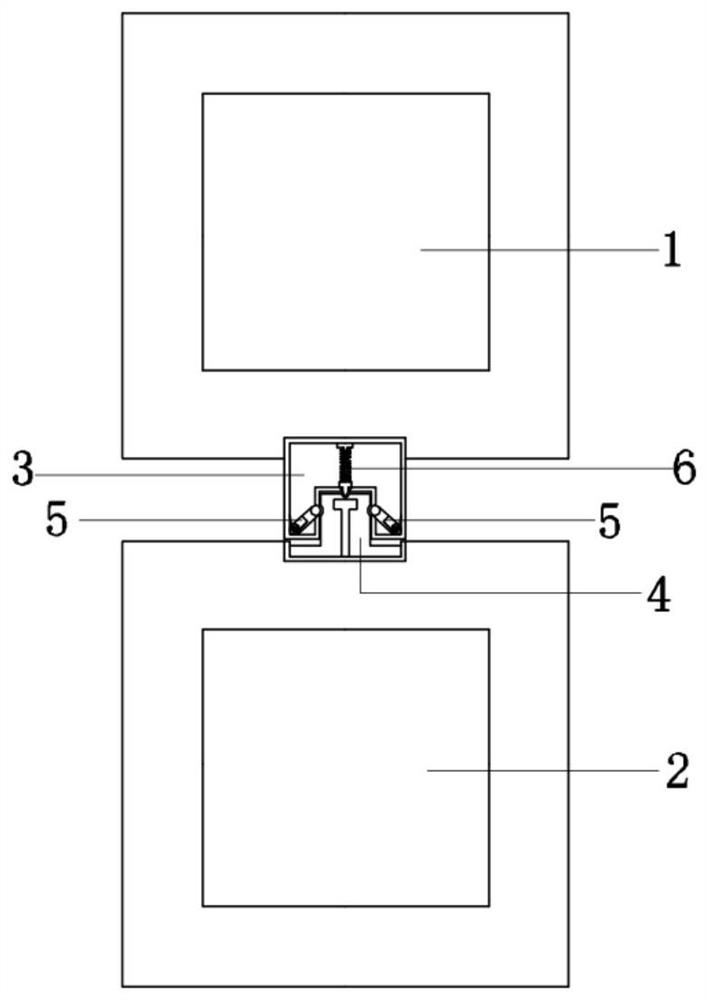

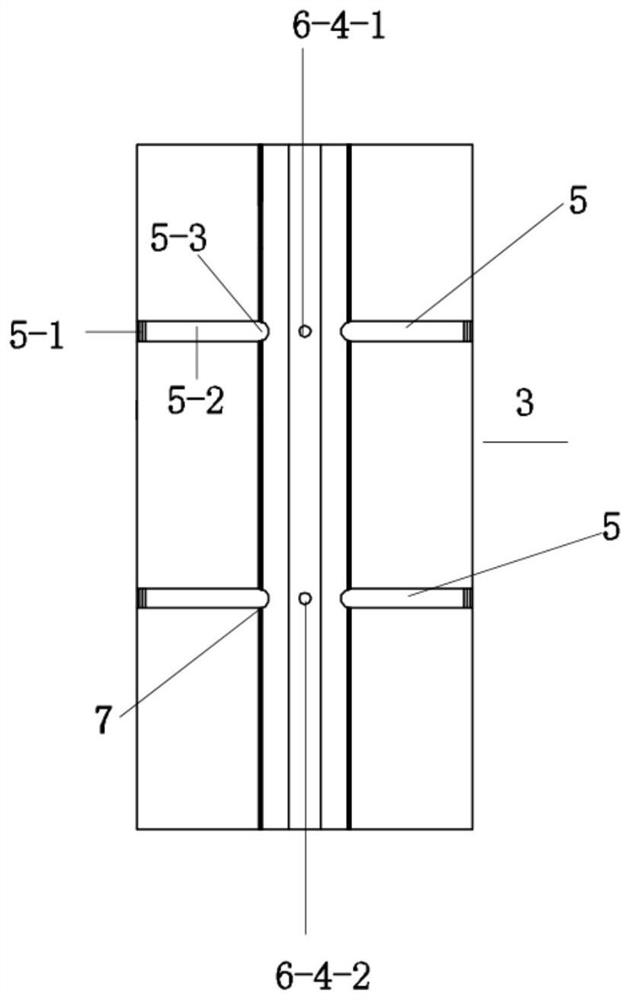

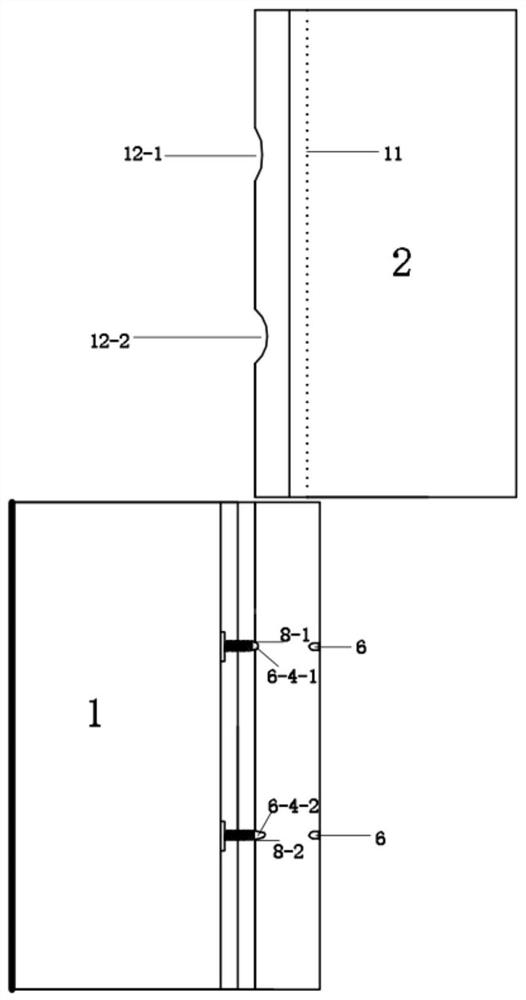

[0047] Step 2, welding the first connecting part 3 on the first steel pipe pile 1, and welding the second connecting part 4 on the second steel pipe pile 2; figure 1 As shown, the first connecting portion 3 includes a concave portion arranged along the entire length of the first steel pipe pile 1; the second connecting portion 4 includes a convex portion arranged along the entire length of the second steel pipe pile 2;

[0048] Step 3: After the drilling is completed, insert and install the first steel pipe pile 1, then lift the second steel pipe pile 2 vertically, and insert the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com