Simulation method for crack subcritical expansion fracture energy of rock double-twist test piece

A simulation method and fracture energy technology, applied in the direction of using stable torsion to test material strength, using stable tension/pressure to test material strength, instruments, etc., can solve the difference of rock heterogeneity, the test loading method is complex and irreversible and other problems to achieve the effect of avoiding engineering instability and damage, saving labor costs and time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

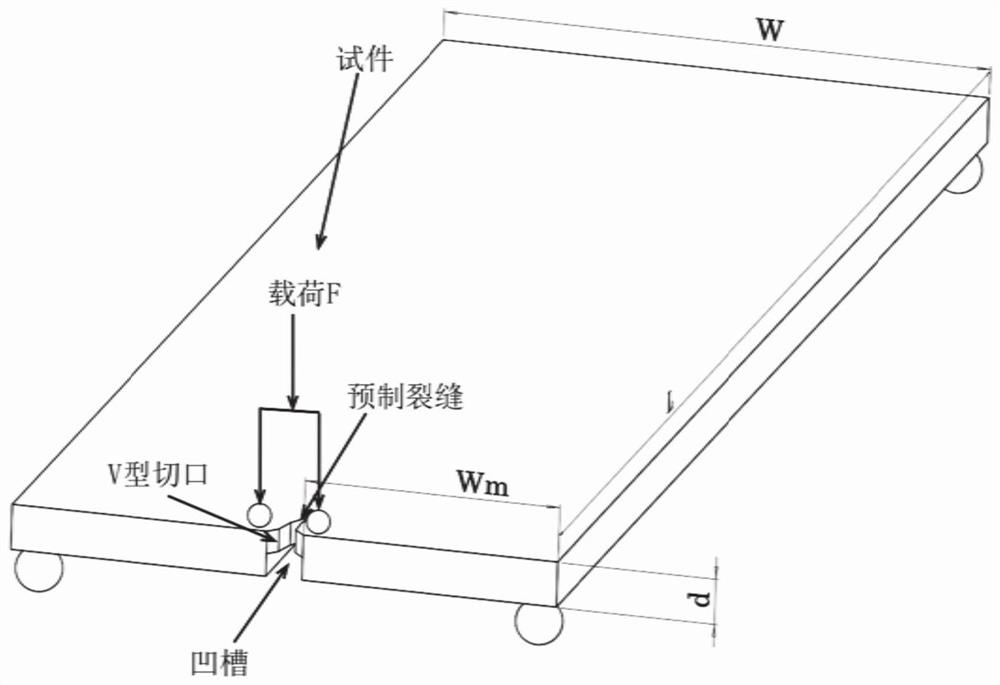

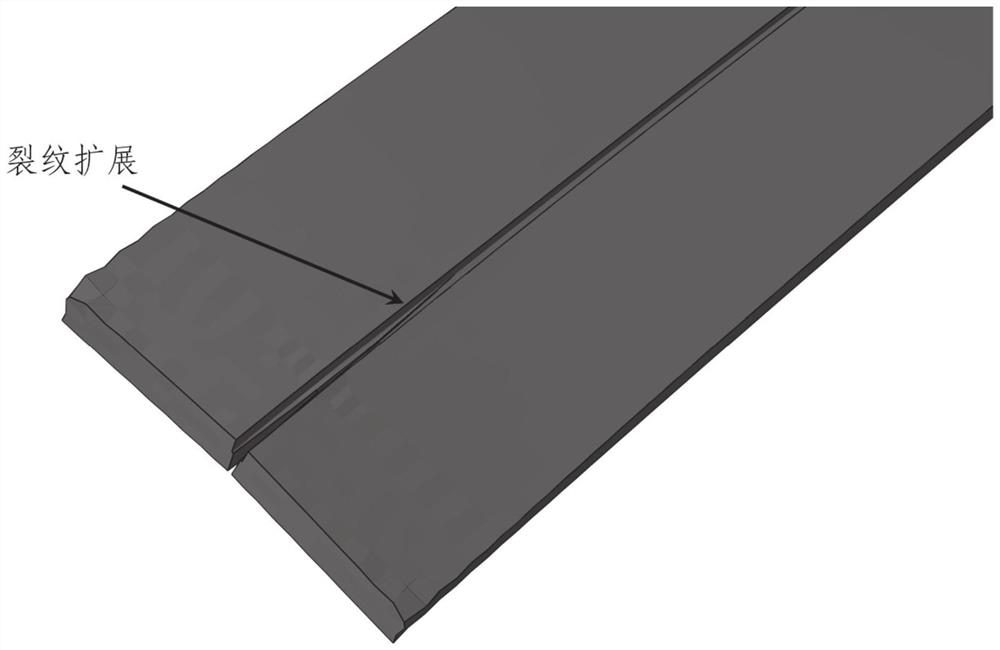

[0037] In a typical implementation of the present disclosure, such as Figure 1-Figure 4 As shown in Fig. 1, a method for simulating the fracture energy of crack subcritical propagation in rock double torsion specimens is proposed.

[0038] Include the following steps:

[0039] Make rock material standard samples and conduct tests to obtain rock material mechanical parameters;

[0040] Make double-torsion specimens and conduct tests to obtain the load relaxation rate and failure load of the specimens;

[0041] Establish the extended finite element model of the double torsion test piece and preset notches and cracks, and substitute the obtained rock material mechanical parameters, load relaxation rate and failure load into the extended finite element model;

[0042] Load the extended finite element model to obtain the preset crack initiation time;

[0043] Define the interaction between cracks, calculate the energy release rate of the crack tip of the double torsion specimen...

Embodiment 2

[0070] In another typical implementation of the present disclosure, as shown in the figure, a method for simulating the crack propagation fracture energy of a rock double torsion specimen is proposed.

[0071] On the basis of Embodiment 1, a set of detailed processes are provided in this embodiment, including the following steps,

[0072] Step 1: Use granite material to make a standard test block, and test its compressive strength and tensile strength;

[0073] In this step, the mechanical parameter test adopts the existing mechanical parameter test process, which will not be repeated here.

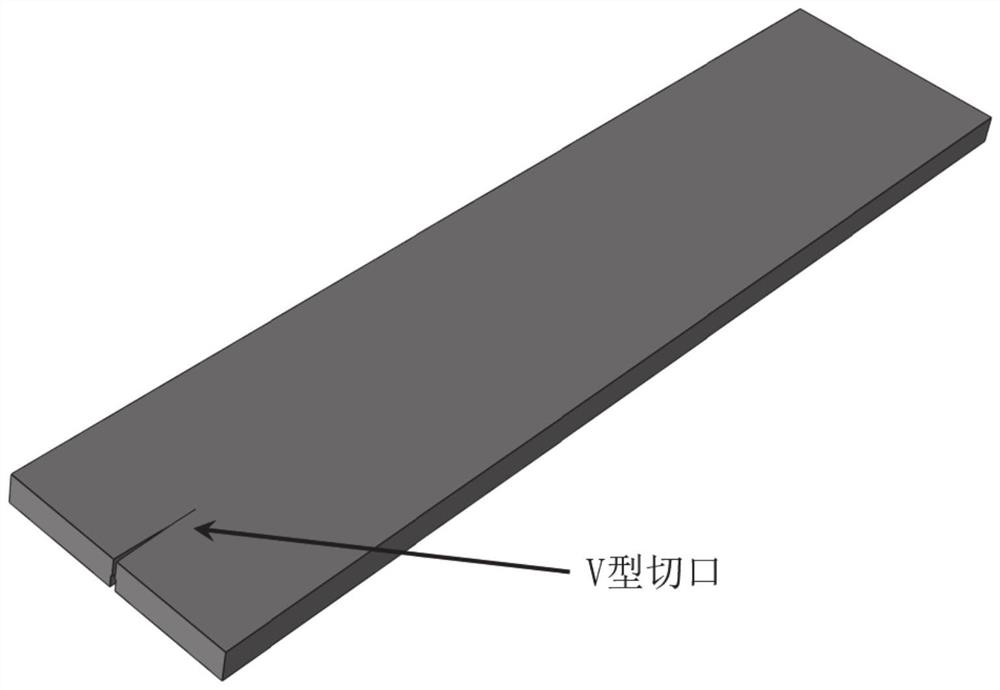

[0074] Step 2: Use the granite material used in step 1 to make a test piece, and process it into a double-torsion test piece with a size of 180mm×60mm×5mm. On the bottom side of the center of the test piece along the length direction, process a V-shaped guide groove with a width of 4 mm and a depth of 2.5 mm along the direction of the slit, and process a slit with a length of 10 mm to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com