Method for detecting bottle opening cracks of liquid-carrying glass bottle

A technology for crack detection and glass bottles, which is applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as eye damage, low detection stability, and ineffective detection of bottle mouth cracks, so as to eliminate interference, The effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

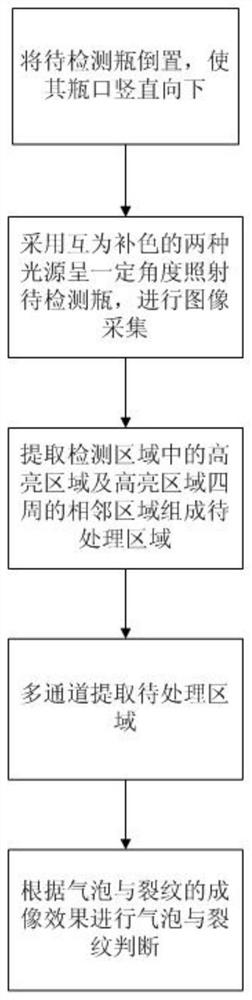

[0034] like figure 2 As shown, this embodiment is mainly aimed at transverse cracks, and the transverse crack detection method is:

[0035] Step 1. Turn the bottle to be tested upside down so that the mouth of the bottle is vertically downward;

[0036] Step 2. Use two light sources of complementary colors to irradiate the bottle to be detected at a certain angle for image acquisition; in this embodiment, red and green strip light sources of complementary colors are used to irradiate the bottle to be detected, and the light sources are installed horizontally on The back side of the bottle to be inspected, and the light source angles are 45° and 60° respectively, and the image is collected around the bottle circumference;

[0037] Step 3, extracting the highlighted area in the detection area and the adjacent areas around the highlighted area to form the area to be processed, which can be extracted by using the threshold method, and the specific extraction steps are existing t...

Embodiment 2

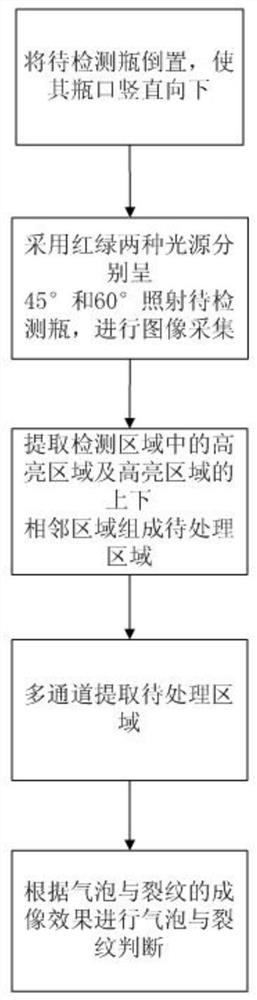

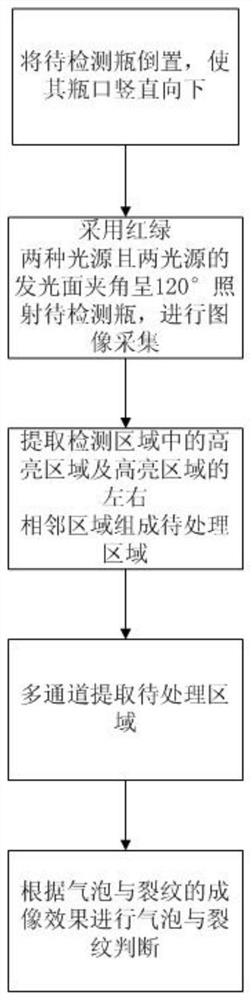

[0043] like image 3 As shown, this embodiment is mainly aimed at vertical cracks, and the detection method for transverse cracks is:

[0044] Step 1. Turn the bottle to be tested upside down so that the mouth of the bottle is vertically downward;

[0045] Step 2. Use two light sources of complementary colors to irradiate the bottle to be inspected at a certain angle for image acquisition; in this embodiment, red strip light sources and green strip light sources of complementary colors are used to illuminate the bottle to be inspected, and the light sources are installed vertically On the back side of the bottle to be detected, and the angle between the light-emitting surfaces of the two light sources is 120°, image acquisition is performed around the bottle;

[0046] Step 3, extracting the highlighted area in the detection area and the adjacent areas around the highlighted area to form the area to be processed, which can be extracted by using the threshold method, and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com