Method for improving operation efficiency of side drainage ship lock by inertia overdrop of water delivery system

A technology for water delivery system and operation efficiency, which is applied in the direction of ship locks, ship lifting devices, data processing applications, etc., and can solve the problems of increasing the lock discharge time, reducing the operating efficiency of the ship lock, and being unable to adapt to different △Z values, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

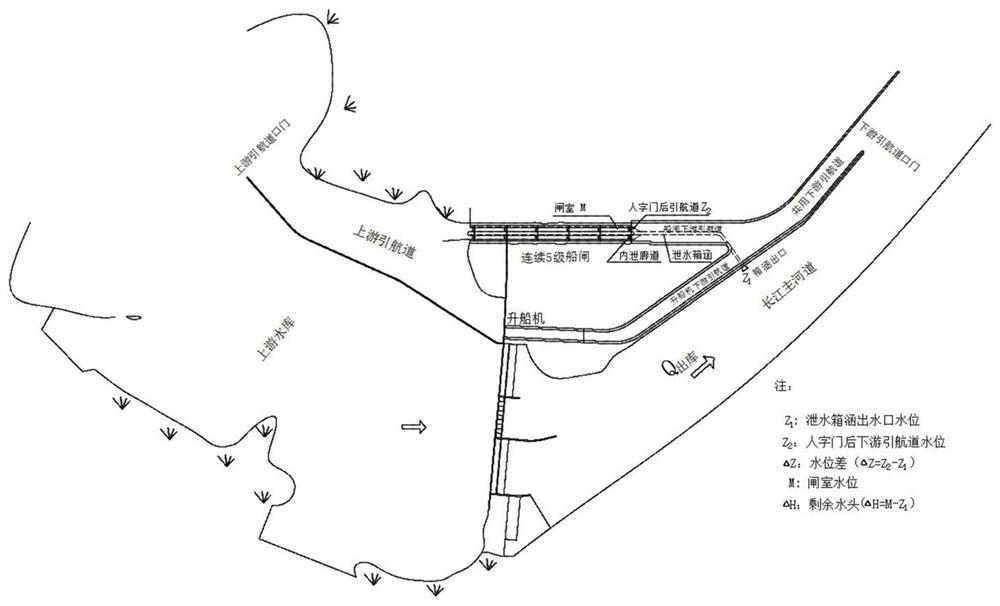

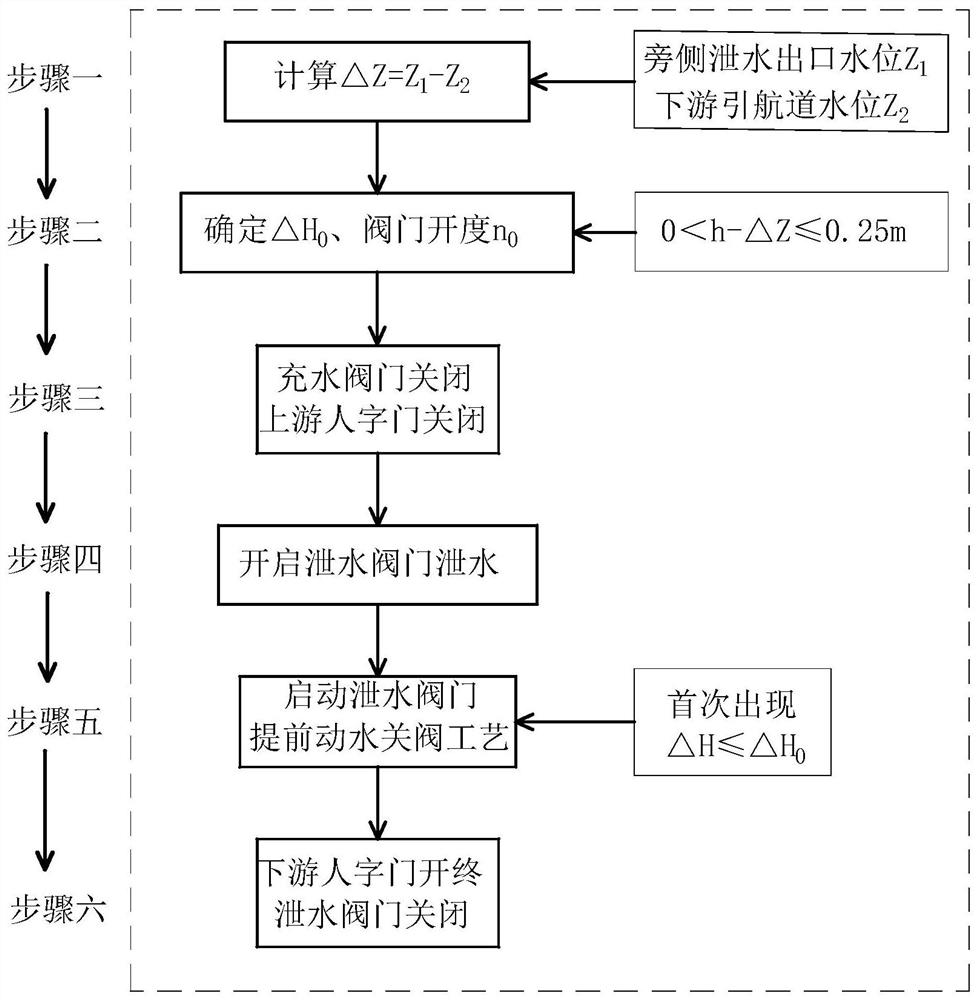

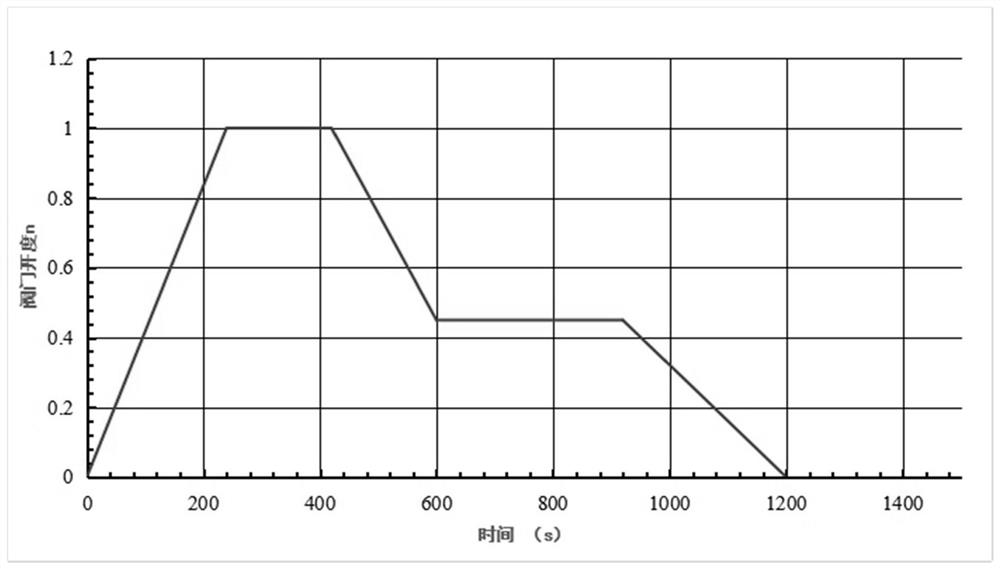

[0033] The ship lock of this embodiment is a high-head ship lock, and a distributed water delivery system is adopted, so that the peak value of the discharge flow of the ship lock is large. In order to reduce the impact of ship lock discharge on the navigable water flow conditions of the downstream approach channel, the ship lock adopts the "internal and external discharge" discharge layout scheme, that is, most of the water body in the lock chamber passes through the main discharge corridor and box culvert with a length of about 1350m ( Also known as side discharge corridor) discharges directly to the main channel, see figure 1. Since the outlet of the box culvert is located upstream of the entrance of the downstream approach channel, and there is a vertical gradient in the water level of the river, the water level at the outlet of the box culvert is higher than that of the downstream approach channel. After the water level is equal, if the water level in the lock chamber in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com