A kind of porous concave cube conp@cosa-n-c catalyst and its preparation method and application

A technology of cube and catalyst, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of Fe-N-C catalyst performance decline, catalyst durability decline, etc., and achieve the effect of improving density, strong durability, and large external surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

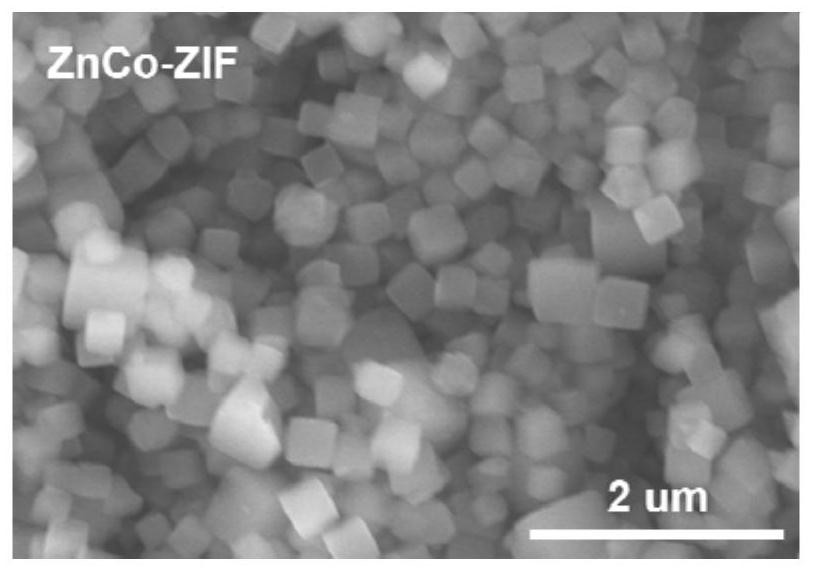

[0041] Synthesis of Example 1 ZnCo-ZIF nanocubes:

[0042] (1) Weigh 2mmol Zn(NO 3 ) 2 .6H 2 O, 0.15mmol Co(NO 3 ) 2 .6H 2 0 and 10mg CTAB (cetyltrimethylammonium bromide), the above-mentioned weighed sample was dissolved in 20mL ultrapure water, vigorously stirred to form a uniform transparent pink A solution.

[0043] (2) Weigh 110mmol of 2-methylimidazole and dissolve it in 140mL of ultrapure water, and stir vigorously to form a uniform transparent B solution.

[0044] (3) Under the condition of 500 rpm, quickly pour the step (1) A solution into the step (2) B solution to form a purple solution, and react at room temperature for 12 hours.

[0045] (4) The material obtained in step (3) is centrifugally washed with a rotating speed of 8000-10000rpm, and the solvent is ultrapure water,

[0046] After extensive washing several times, it was then dried overnight at 60 °C.

Embodiment 2

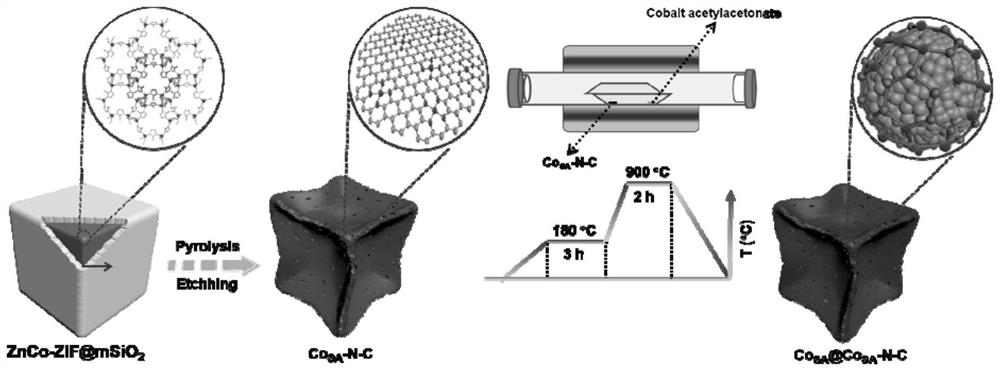

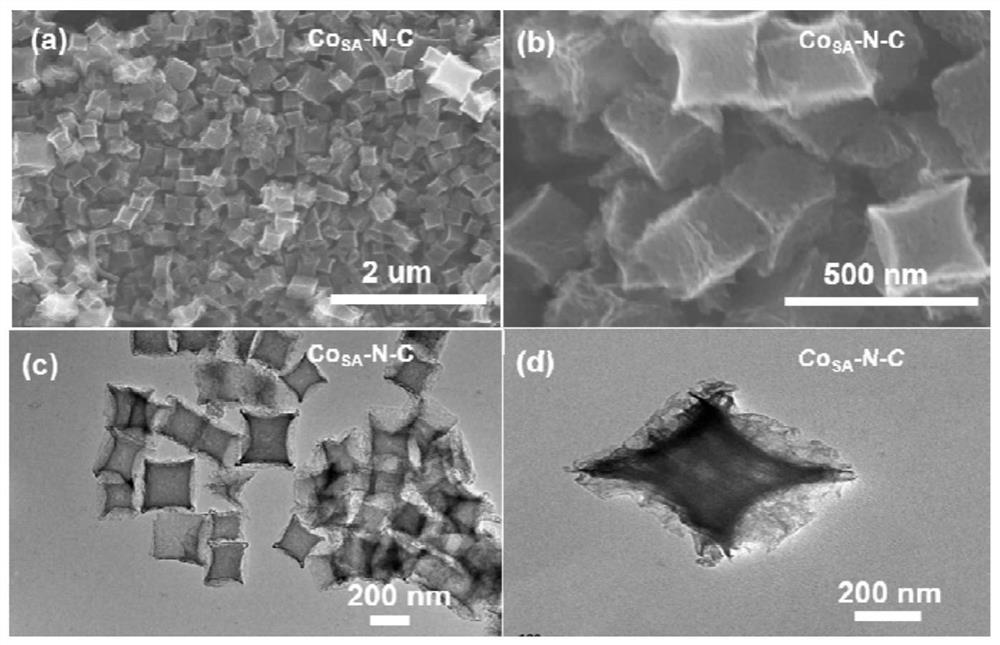

[0047] Example 2 Porous concave cube Co SA Synthesis of -N-C:

[0048] (1) Weigh 500 mg of ZnCo-ZIF synthesized in Example 1 and dissolve it in 240 mL of ultrapure water, and stir at 500 rpm to form a uniform purple solution.

[0049] (2) After the solution was stirred for 15 minutes in step (1), 6 mL of cetyltrimethylammonium bromide was added successively to the above solution to dilute the aqueous solution (25 mg mL -1 ) and 10mL aqueous sodium hydroxide solution (6mg mL -1 ), and stirred for 15 minutes. Thereafter, tetraethyl orthosilicate (1.2 mL of a solution in 6 mL of methanol) was injected into the above solution to allow it to react.

[0050] (3) The reaction time in step (2) is 1-6h.

[0051] (4) Centrifuge and wash the materials synthesized at different times in step (3) to prepare silica-wrapped ZnCo-ZIF materials with different thicknesses (ZnCo-ZIF@mSiO 2 ).

[0052] (5) ZnCo-ZIF@mSiO obtained in step (4) 2 Heated at 450°C for 3h under Ar atmosphere, then...

Embodiment 3

[0054] Example 3 Porous concave cube Co NP @Co SA Synthesis of -N-C:

[0055] (1) take by weighing the Co synthesized by 40mg embodiment 2 SA -N-C black powder and a certain amount of cobalt acetylacetonate were placed on the upstream side and bottom of the porcelain boat, respectively.

[0056] (2) The mass of cobalt acetylacetonate in step (1) is 1-8 mg.

[0057] (3) Put the ceramic boat in the step (1) into the tube furnace and flush it with argon, then place the center of the furnace at 2°C min -1 The heating rate was raised to 180°C and kept at this temperature for 3h. Then at 5°C min -1 The rate was further raised to 900°C, held there for 3 hours for pyrolysis, and then cooled to room temperature.

[0058] The porous concave cube Co NP @Co SA The size of the -N-C catalyst is 200-400nm, and the size of Co particles is 5-15nm.

[0059] N2 adsorption isotherm test results, the porous concave cube Co NP @Co SA -N-C catalyst specific surface area is 804.3m 2 g -1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com