A communication power distribution cabinet

A technology for communication power supply and power distribution cabinet, which is applied to substation/distribution device casings, electric components, electromechanical devices, etc., can solve the problems of dust filter not being able to filter dust, clogging of filter eyes, and easy clogging of dust filter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

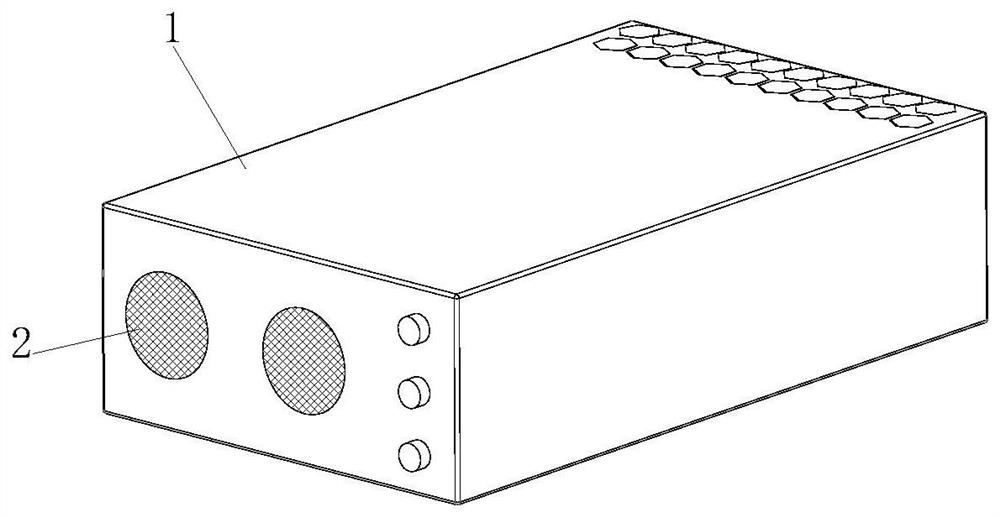

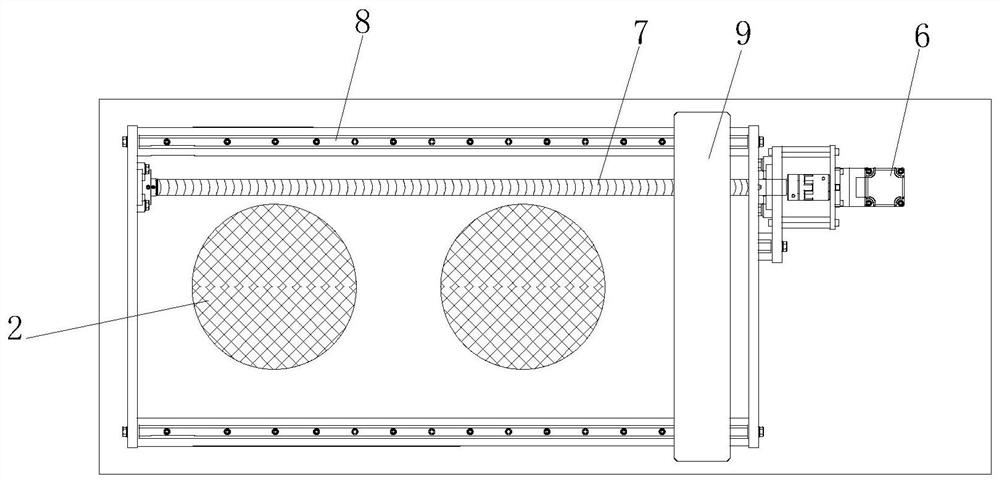

[0038] like Figure 1-Figure 4As shown, a communication power distribution cabinet according to the present invention includes a cabinet body 1, the cabinet body 1 has a square box-like structure, and the interior of the cabinet body 1 is hollow to form an installation cavity for installing circuit components. The side of the cabinet body 1 is provided with a heat dissipation hole which communicates with the installation cavity.

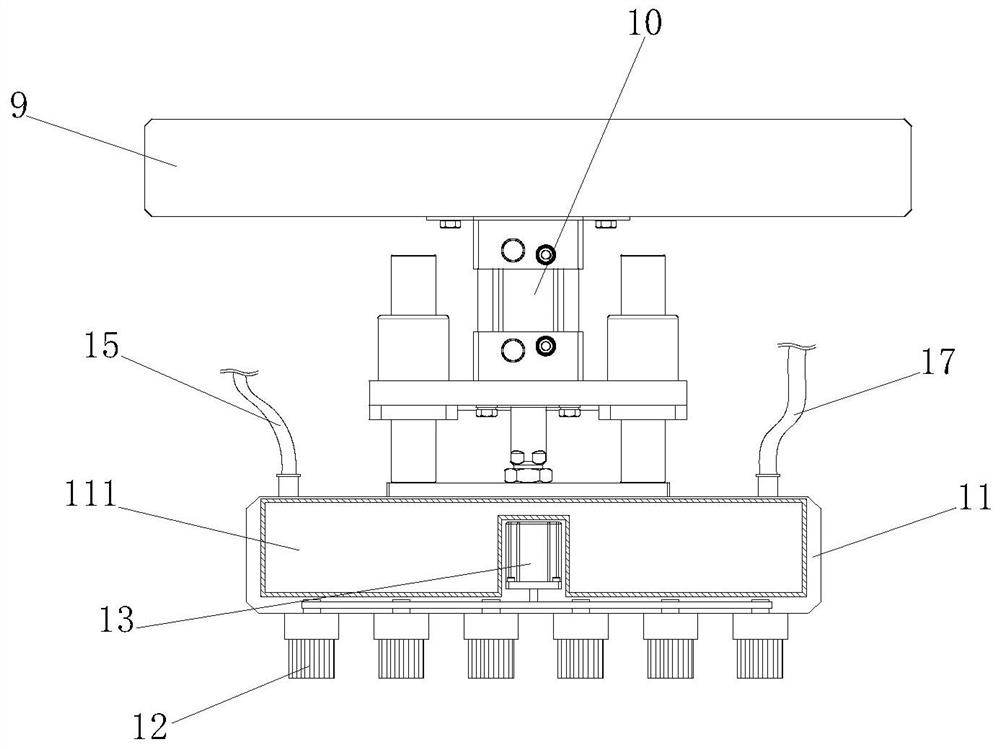

[0039] The communication power distribution cabinet also includes a cleaning mechanism arranged in the installation cavity for cleaning the dust filter 2. The cleaning mechanism specifically includes a dust sensor 3, a wind speed sensor 4, a controller 5, a driving member 6, a transmission Assembly 7 , guide member 8 , sliding seat 9 , telescopic member 10 , brush head seat 11 , brush head 12 and brush head motor 13 .

[0040] Both the dust sensor 3 and the wind speed sensor 4 are arranged on the inner side of the cooling fan, and correspond to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com