Intelligent automatic deicing robot for ultra-high voltage power grid cable

A technology of ultra-high voltage and robotics, which is applied in the installation of cables, electrical components, and overhead installations, etc. It can solve the problems of low deicing efficiency, continuous swinging of cables, and falling off of crushed ice, so as to avoid incomplete crushed ice and improve Deicing efficiency, effect of reducing torsional force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

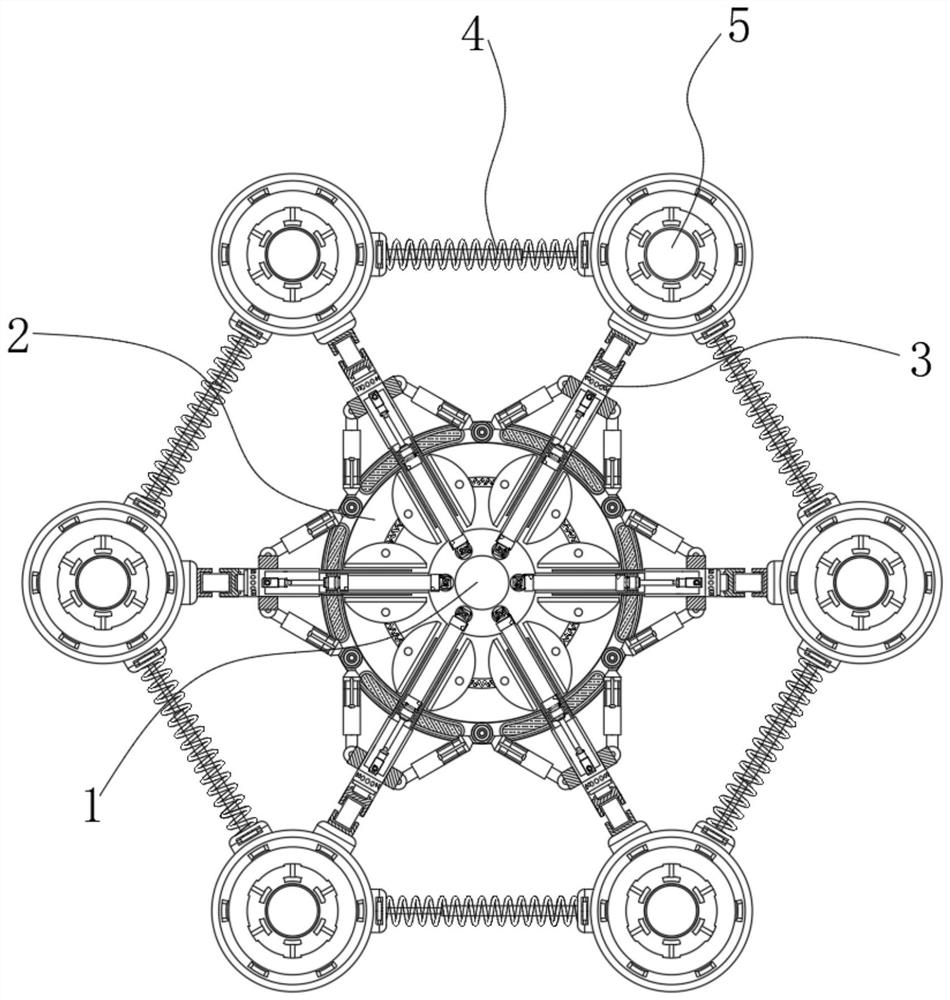

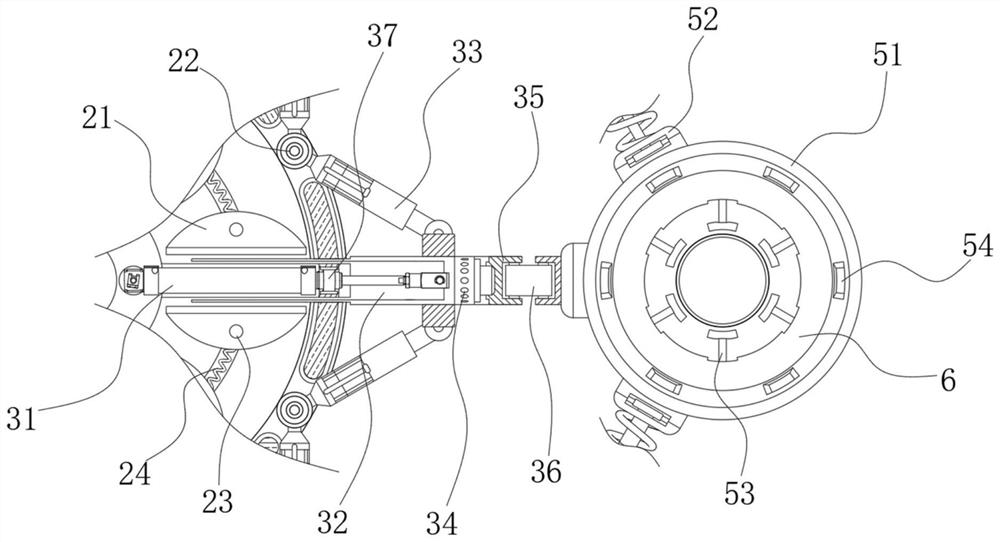

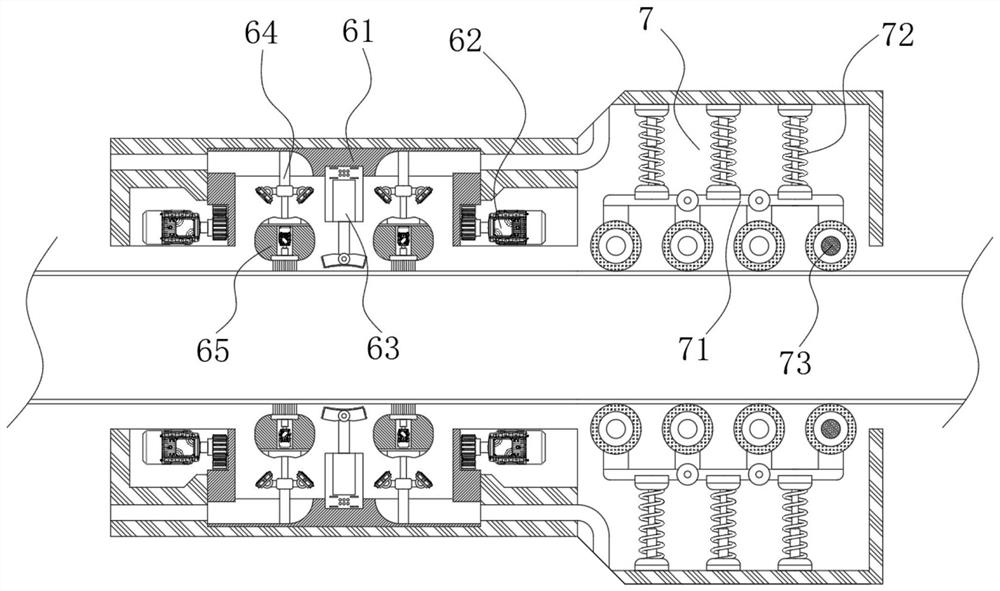

[0025] refer to figure 1 , the present invention provides a technical solution: an intelligent automatic deicing robot for ultra-high voltage power grid cables, which includes a sensing wheel box 1, a guide plate box 2, a stabilization device 3, an elastic rod 4 and an ice crushing device 5, the guide The disk case 2 is a double-layered hollow structure, so that the sensing wheel case 1 is concentrically embedded in the guide disk case 2, and the side of the guide disk case 2 is provided with arc-shaped cavities, and multiple groups are arranged. There is a stabilizing device 3 in the middle, and the outer side of the stabilizing device 3 is connected with an ice crushing device 5, and the center of the ice crushing device 5 is a hollow structure, so that the cable can be introduced into the ice crushing device 5;

[0026] And the other side of the ice crushing device 5 corresponding to the stabilization device 3 is provided with a clamping cavity, so that the ice crushing dev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap