Injection bottle efficient and fine crushing equipment for medical recovery

An injection bottle and fine crushing technology is applied in the field of high-efficiency fine crushing equipment for medical recycling injection bottles, which can solve problems such as harming the human body and polluting the air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A high-efficiency fine crushing equipment for injection bottles for medical recycling, such as figure 1 As shown, it includes a support frame 1, a crushing and screening mechanism 2, a screening and vibration mechanism 3 and a secondary extrusion mechanism 4. The upper side of the support frame 1 is provided with a crushing and screening mechanism 2, and the support frame 1 is provided with a screening and vibration mechanism 3. , There is a secondary extrusion mechanism 4 between the crushing screening mechanism 2 and the screening vibration mechanism 3 .

[0063] When people need to crush injection bottles, they can use this high-efficiency crushing equipment for injection bottles for medical recycling. First, people put the injection bottles in the crushing and screening mechanism 2, and then start the crushing and screening mechanism 2 to crush the injection bottles. The crushed injection bottle falls into the screening and vibrating mechanism 3, and the secondary e...

Embodiment 2

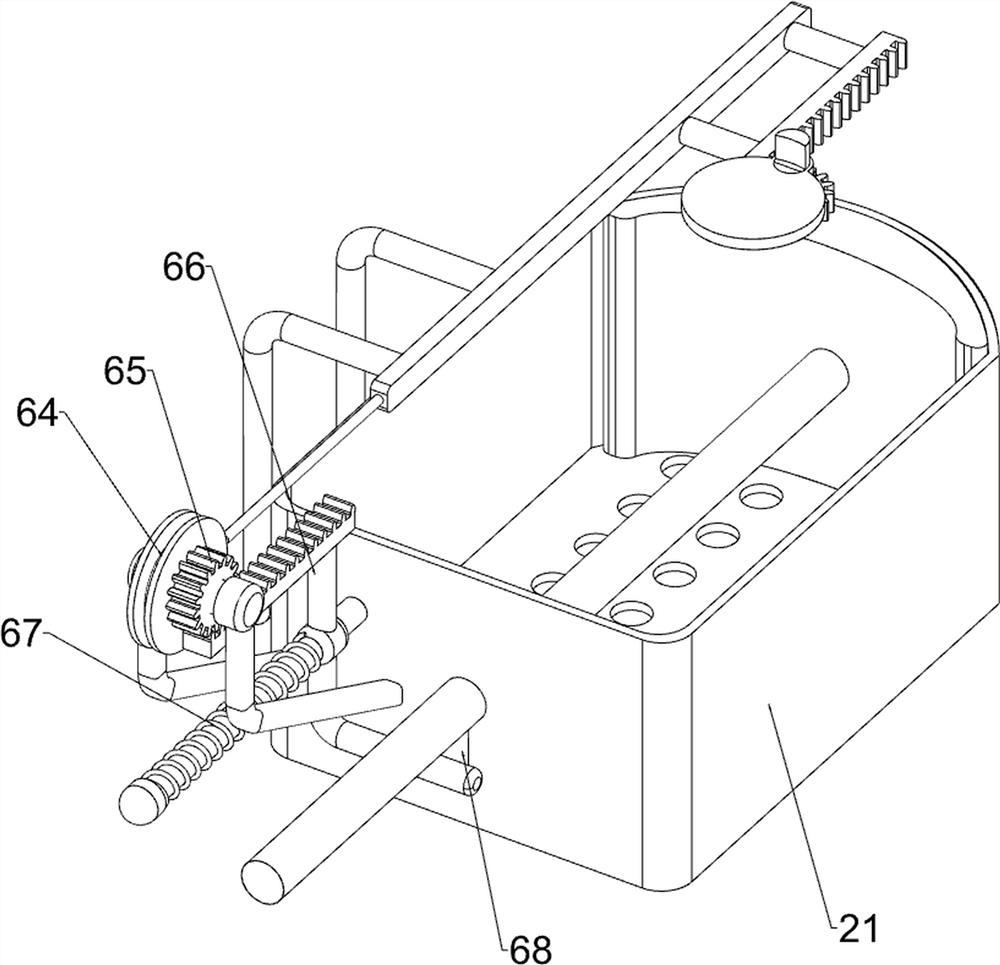

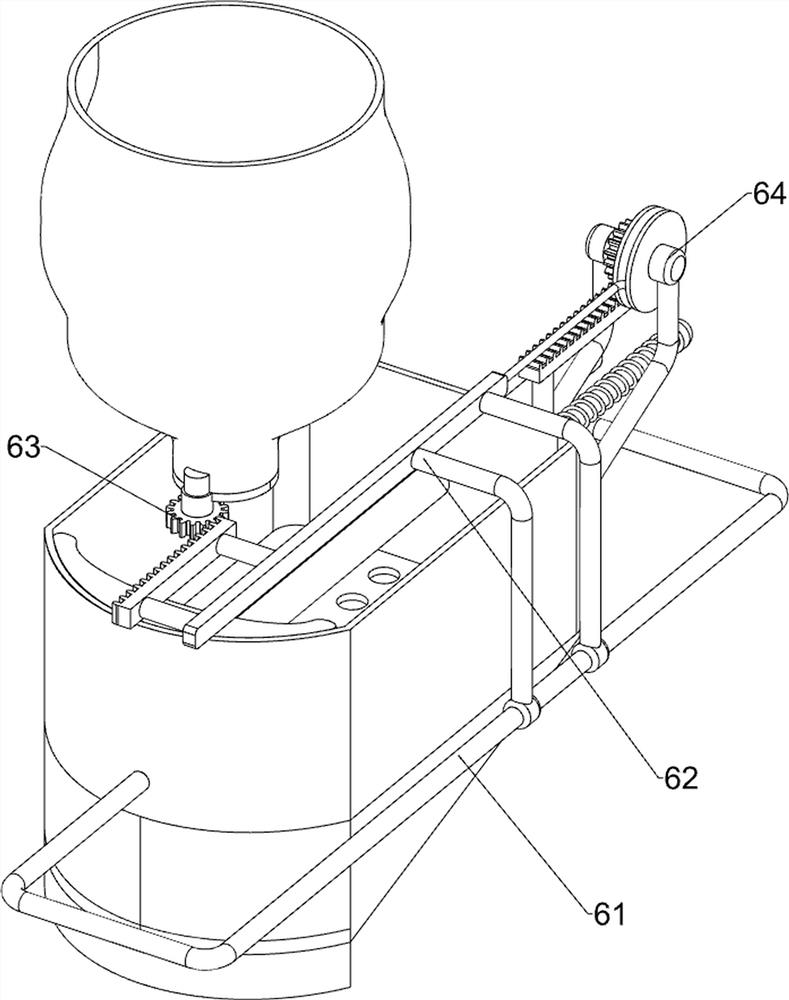

[0065] On the basis of Example 1, such as Figure 2-4 As shown, the crushing and screening mechanism 2 includes a screening connection frame 21, a cylinder 22 and an extruding rod 23. The upper side of the support frame 1 is provided with a screening connection frame 21, and the rear side of the support frame 1 is equipped with a cylinder 22. On the telescopic rod of the cylinder 22 An extruding rod 23 is connected, and the extruding rod 23 is slidably connected with the screening connection frame 21 .

[0066] First, people put the injection bottle in the screening connection frame 21, then start the cylinder 22, and the telescopic rod of the cylinder 22 drives the extrusion rod 23 to reciprocate back and forth, which realizes the operation of squeezing the injection bottle. Cylinder 22 is closed.

[0067] The screening vibration mechanism 3 includes a first connecting rod 31, a shaking discharge frame 32 and a first spring 33. The support frame 1 is symmetrically slidable on ...

Embodiment 3

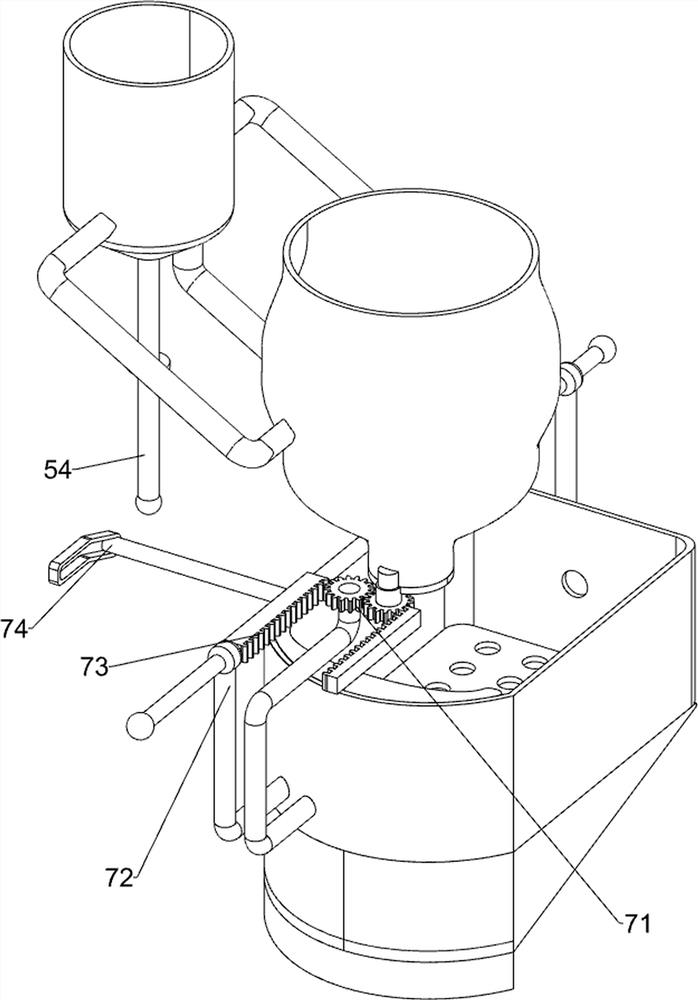

[0072] On the basis of Example 2, such as Figure 5-8 As shown, it also includes a disinfection blanking mechanism 5, which includes a discharge frame 51, a rotating discharge plate 52, a water discharge frame 53, a slide switch 54 and a second spring 55, and the front side of the right part of the support frame 1 A discharge frame 51 is provided, the bottom of the discharge frame 51 is rotatably provided with a rotary discharge plate 52, the left side of the discharge frame 51 is provided with a water release frame 53, and the slide switch 54 is provided on the water discharge frame 53, and the slide switch 54 and A second spring 55 is connected between the water discharge frames 53 , and the second spring 55 is wound on the slide switch 54 .

[0073] People manually move the slide switch 54 upwards, and the second spring 55 is compressed, so that the disinfectant water in the water discharge frame 53 enters the discharge frame 51, and the injection bottles in the discharge f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com