3D printing connecting device with enhanced forming control, printing device and printing method

A connecting device and 3D printing technology, applied in the field of 3D printing, can solve the problems of inability to achieve enhanced molding and curing effect and high operability, and achieve the effects of simplifying 3D discharging steps, simplifying complex structures, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

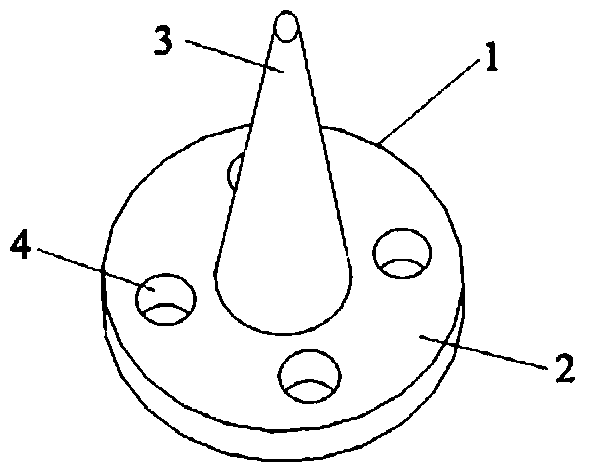

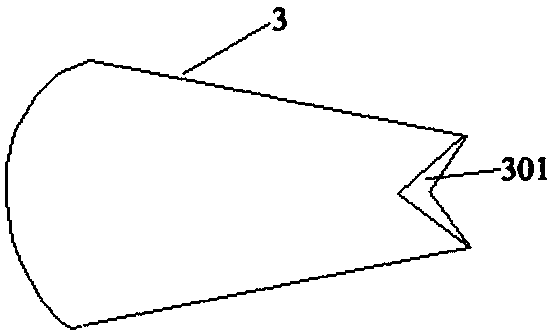

[0044] Such as Figures 1 to 5 As shown, this embodiment provides a 3D printing functional connection device 1 that enhances molding control, including: a body, and a connecting part provided on the body for detachable connection, characterized in that the functional connection device 1 A channel for material liquid extrusion is provided, and a solidification forming control unit 2 and / or a discharge forming control unit 3 are respectively provided along the direction of the channel, wherein the discharge forming control unit 3 is used to control the extrusion of the material liquid The wire diameter structure; the solidification molding control unit 2 is used to control the solidification molding of the material liquid extrusion.

[0045] Specifically, the functional connecting device 1 is detachably connected to the 3D printing device through the connecting part, and the detachable connection includes but not limited to: threaded connection, snap connection, nested connectio...

Embodiment 2

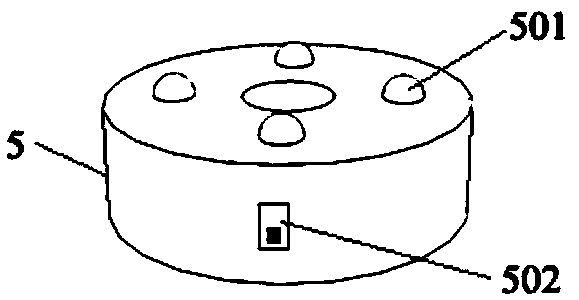

[0062] Such as Figures 1 to 7 As shown, based on the basis of Embodiment 1, this embodiment provides a 3D printing device with enhanced molding control, which is characterized in that it includes: a feeding device 6 for supplying the material liquid, and a device for extruding the material liquid A discharge device 7, the discharge device 7 is connected with the 3D printing functional connection device 1 as described in any one of Embodiment 1, wherein, the functional connection device 1 is connected to the discharge device 7 through the connection part Make a detachable connection.

[0063]Specifically, there is a sealed matching connection between the feeding device 6 and the discharging device 7, and the sealing matching connection can be sealed by setting a sealing device, and the sealing device can be made of hard plastic, thermosolid, ceramic or metal, in practical applications, a sealing gasket can be used, and the sealing device can be set as a sealing ring or a seal...

Embodiment 3

[0072] Such as Figure 8 As shown, this embodiment provides a 3D printing method for enhanced molding control, which is characterized in that it includes the following steps:

[0073] Step 1, connecting the feeding device, the discharging device, and the functional connection device in sequence;

[0074] Step 2, setting a channel for material liquid extrusion in the functional connection device, and respectively setting a solidification forming control unit and / or a discharge forming control unit along the direction of the channel;

[0075] Step 3, controlling the wire diameter structure of the extruded material liquid through the discharge forming control unit;

[0076] Step 4, controlling the curing and molding of the material liquid extrusion through the curing and molding control unit.

[0077] Preferably, said step 4 also includes the following steps:

[0078] The curing and forming control unit is set as a light curing and forming control unit, and the light curing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com