Rolling tool and rolling method for automobile trunk sealing strip

A sealing strip and trunk technology, applied in the rolling field of rolling tools, can solve problems such as difficult to achieve rapid adjustment of spring preload force, lack of control of clamping force, etc., to improve installation efficiency, improve installation effect, and improve The effect of power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

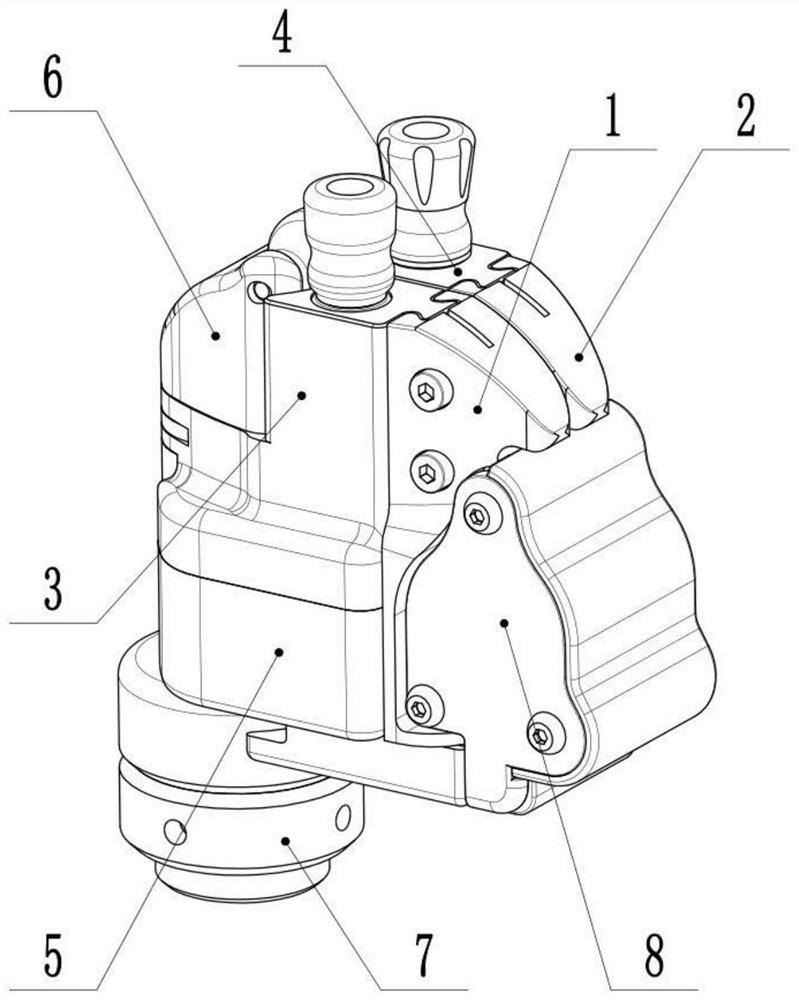

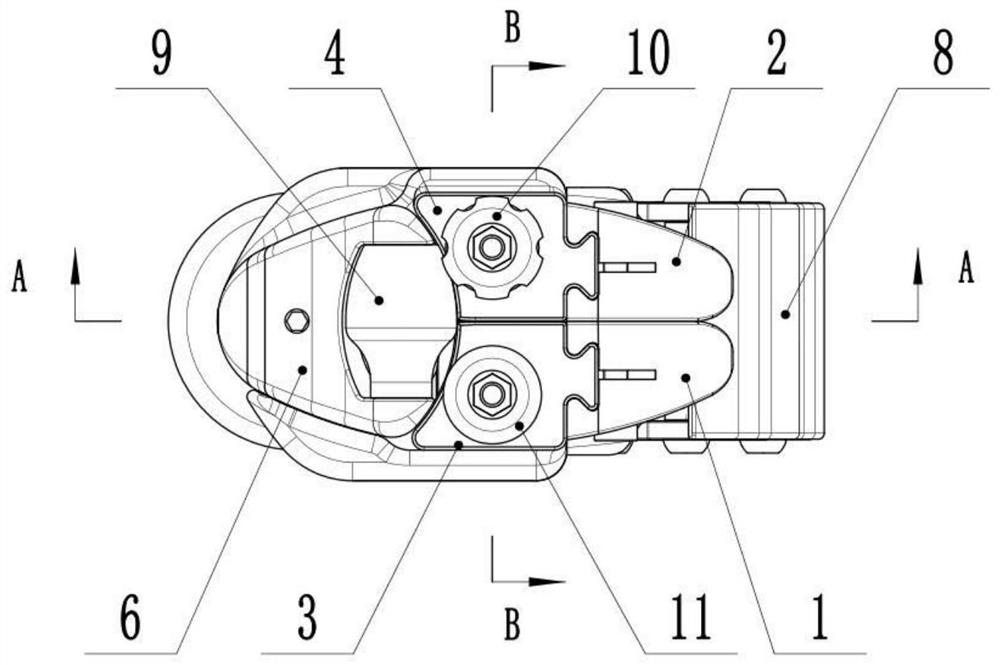

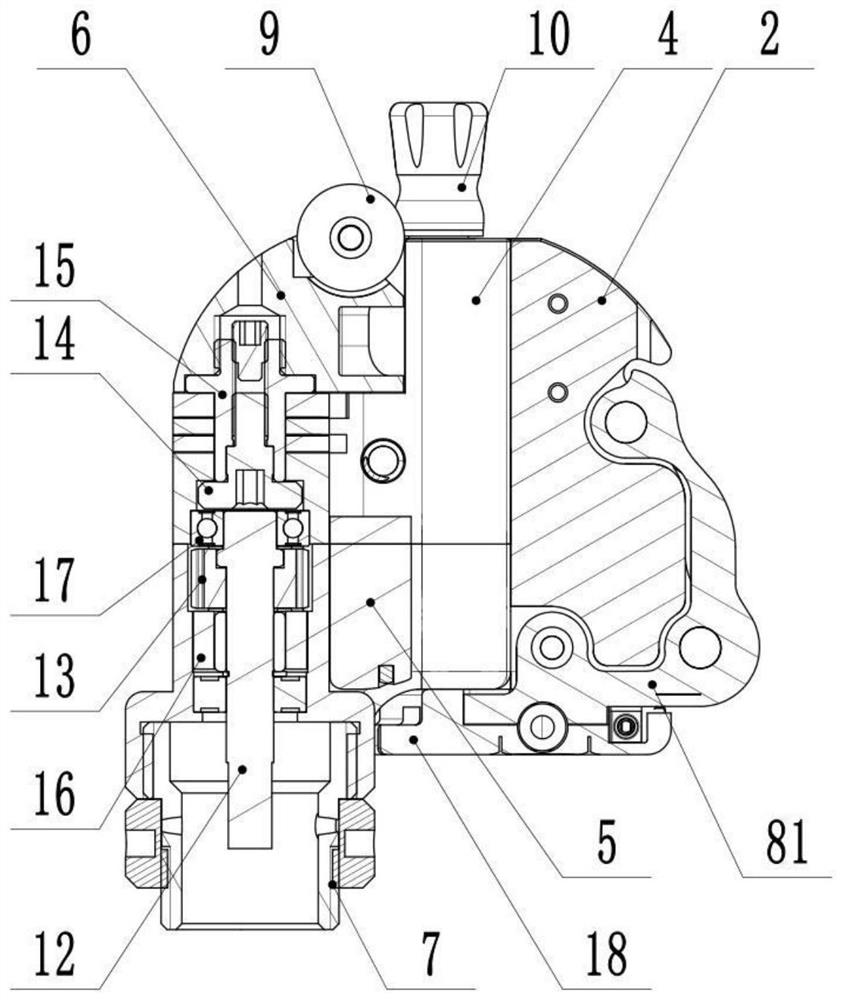

[0045] Such as figure 1 The shown rolling tool for the sealing strip of the automobile trunk is an auxiliary sealing strip installation tool to ensure that the sealing effect of the vehicle meets the process requirements. It is used to ensure that the sealing strip and the body sheet metal are fully bonded and have sufficient bonding force, thereby improving the installation effect of the sealing strip. The rolling tool uses a hinged structure for the left arm and the right arm, so that the left drive shaft and the right drive shaft form an adjustable wheelbase, which can be applied to more car models and has better versatility. The tensioning part in the rolling tool uses a pair of diaphragm cylinders to transmit the pressure of the air source through the pressure plate to the left arm and the right arm respectively to provide clamping force...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap