Concrete mixing plant and feeding method thereof

A mixing plant and concrete technology, applied in mixing plants, chemical instruments and methods, clay preparation devices, etc., can solve problems such as reducing the production efficiency of concrete production, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-5 The application is described in further detail.

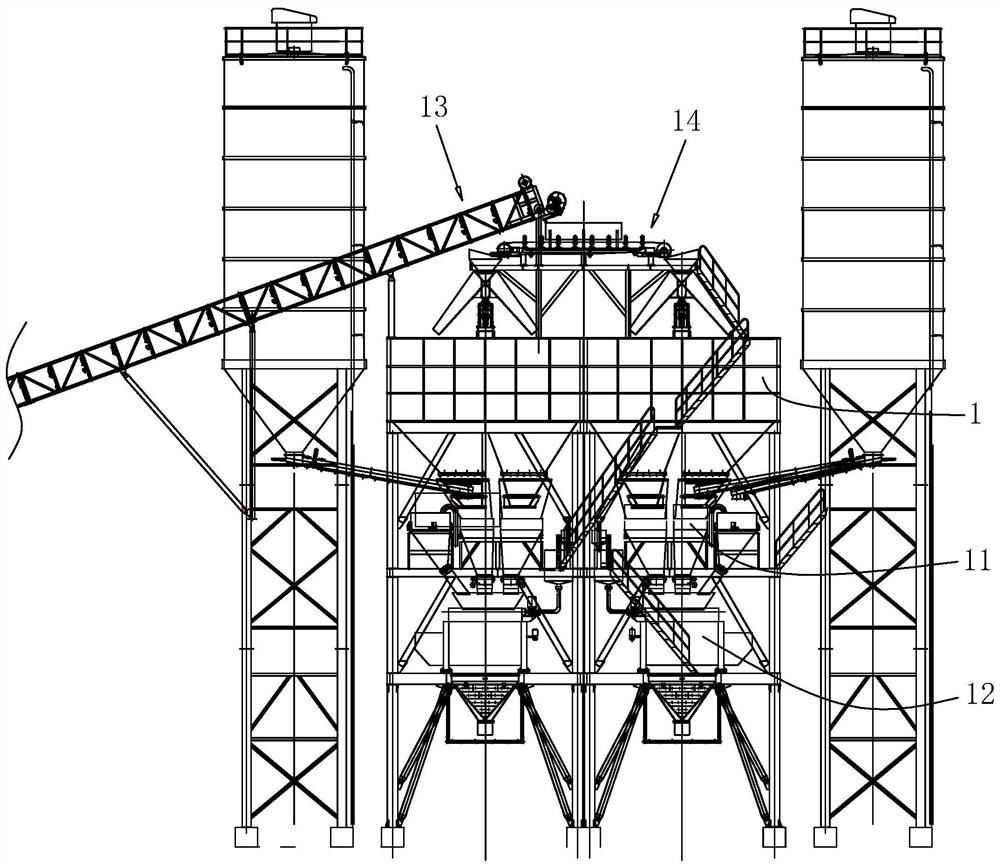

[0040] The embodiment of the present application discloses a concrete mixing building. refer to figure 1 , a concrete mixing building, including two groups of batching devices, the two groups of batching devices include four buffer buckets 1 arranged side by side, each buffer bucket 1 is provided with a metering bucket 11 at the discharge end, and every two metering buckets 11 A mixer 12 is arranged below, and the concrete mixing building also includes a belt conveyor 13.

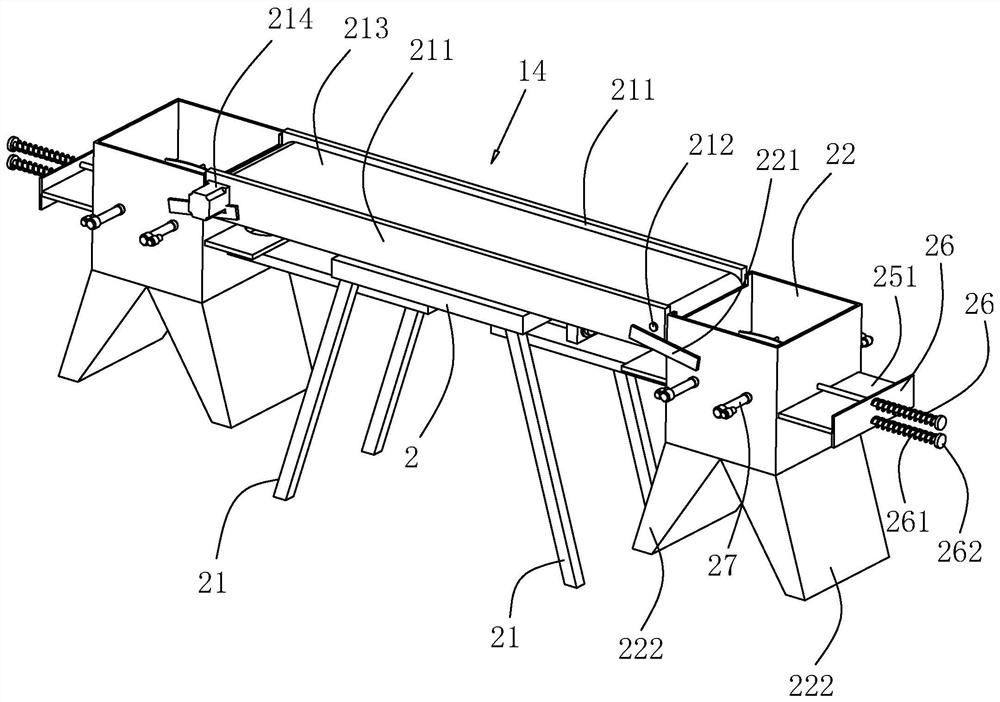

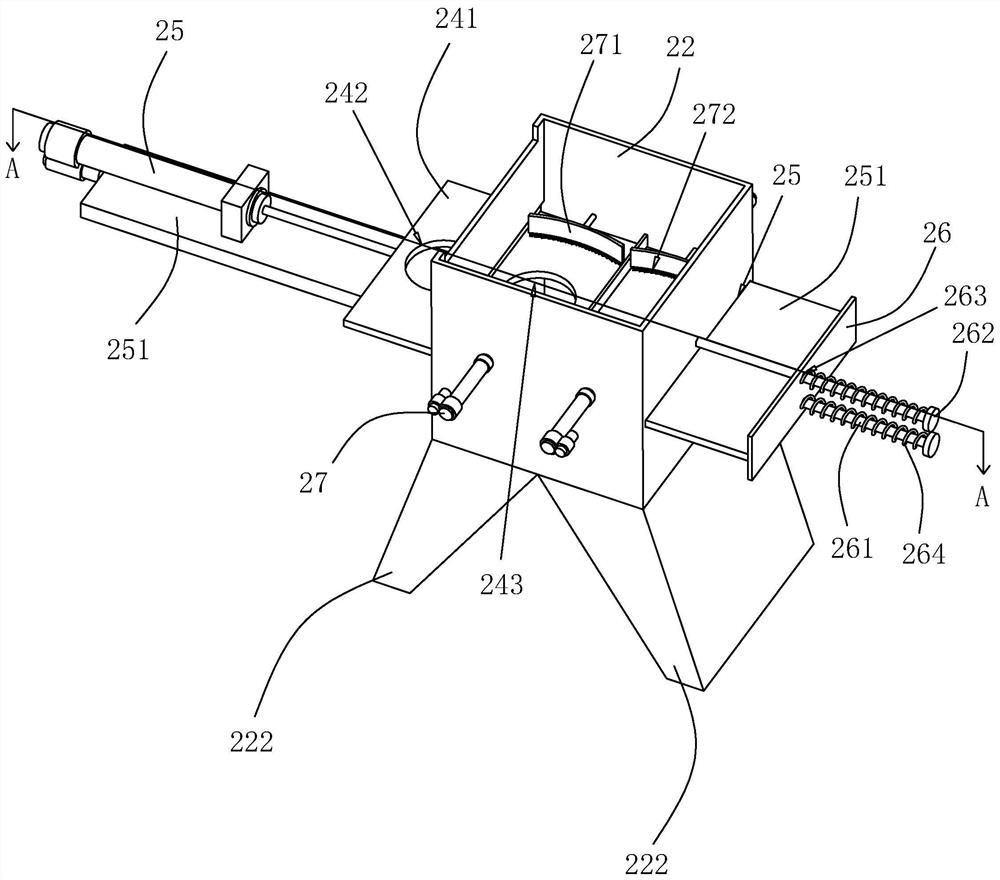

[0041] combine figure 1 with figure 2 , on the frame body and at the position where the feed ends of the buffer buckets 1 on both sides are provided with a material distribution device 14, the material distribution device 14 includes a primary material distribution device, and the initial material distribution device includes installations erected above a plurality of buffer buckets 1 Plate 2, the surface of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap