Mold cavity cooling water channel structure combining circulating water channel and spiral water channel

A technology of cooling water channel and circulating water channel, which is applied in the field of mold cavity cooling water channel structure, can solve the problems of uneven circumferential cooling and uneven cooling of the outer surface temperature of the preform, and achieve the effect of improving cooling uniformity and solving differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

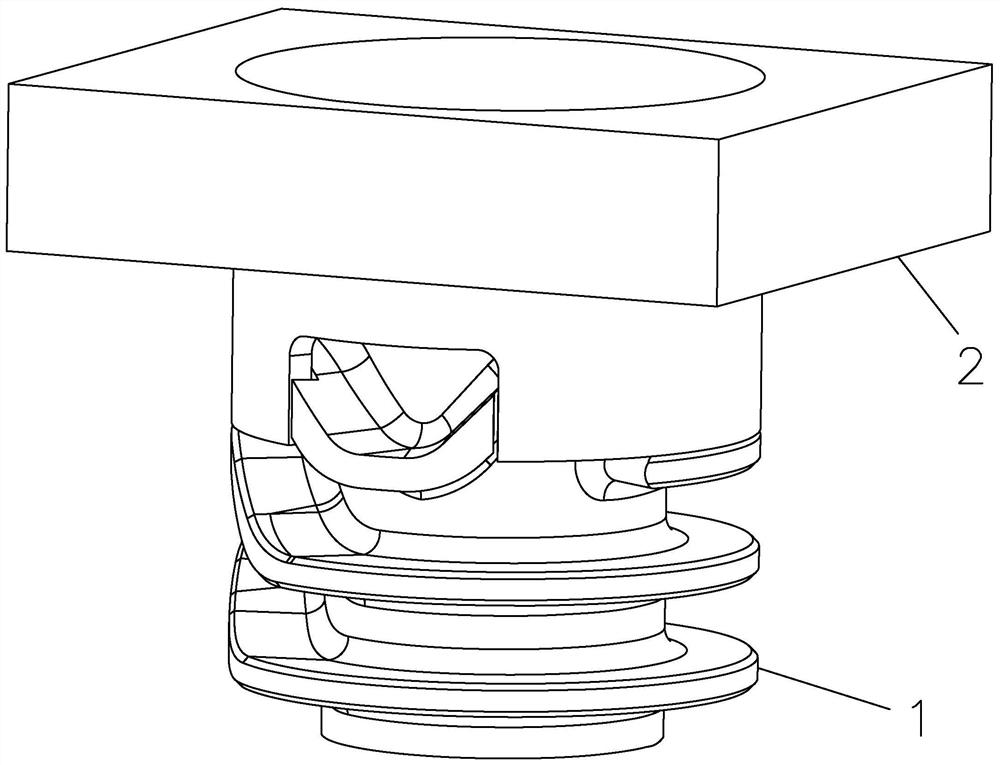

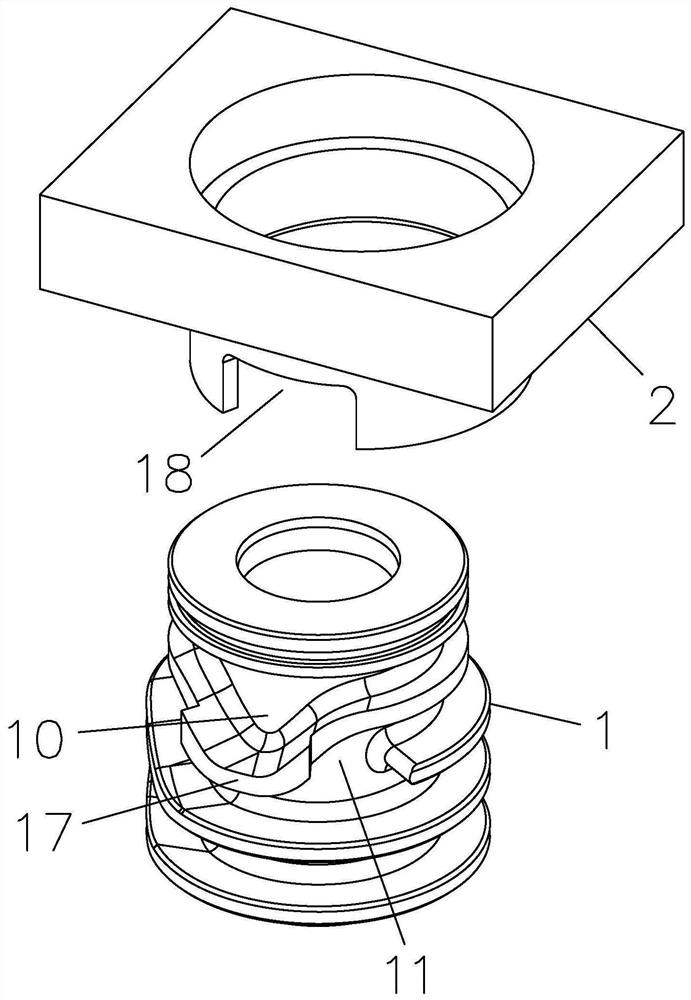

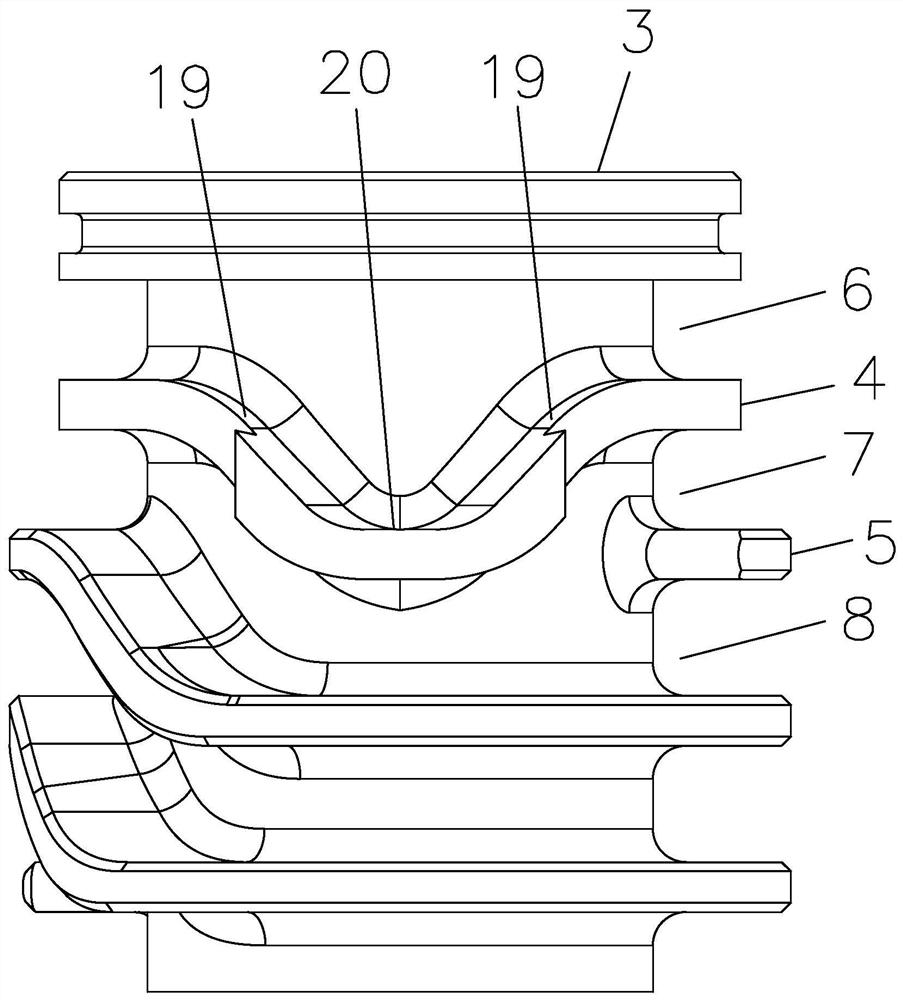

[0024] like Figure 1 to Figure 5 As shown, this embodiment discloses a mold cavity cooling waterway structure in which a circulating waterway and a spiral waterway are combined, including a mold body 3, a first rib 4 and a second rib 5, and the mold body 3 is provided with a The molding cavity for bottle preform molding, the first reinforcing rib 4 and the second reinforcing rib 5 are distributed on the outer wall of the mold body 3 at a certain distance, and the first reinforcing rib 4 surrounds the outer wall of the mold body 3 The outer wall, the second reinforcing rib 5 spirally surrounds the outer wall of the mold body 3, the first reinforcing rib 4 is distributed at a certain distance from the end of the mold body 3 to form a first circulating water tank 6, and the first reinforcing rib 4 A reinforcing rib 4 and the second reinforcing rib 5 are distributed at a certain distance to form a second circulation water tank 7, and the second reinforcing rib 5 spirally surround...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com