Seat cushion structure and manufacturing method thereof

A manufacturing method and seat technology, applied in the direction of seat frames, cabin seats, seat layout, etc., can solve the problems of complicated production process, VOC environmental protection and health, and many metals, so as to improve the appearance quality and reduce the Product weight and reduction in sewing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The application will be further described below in conjunction with the accompanying drawings and specific embodiments:

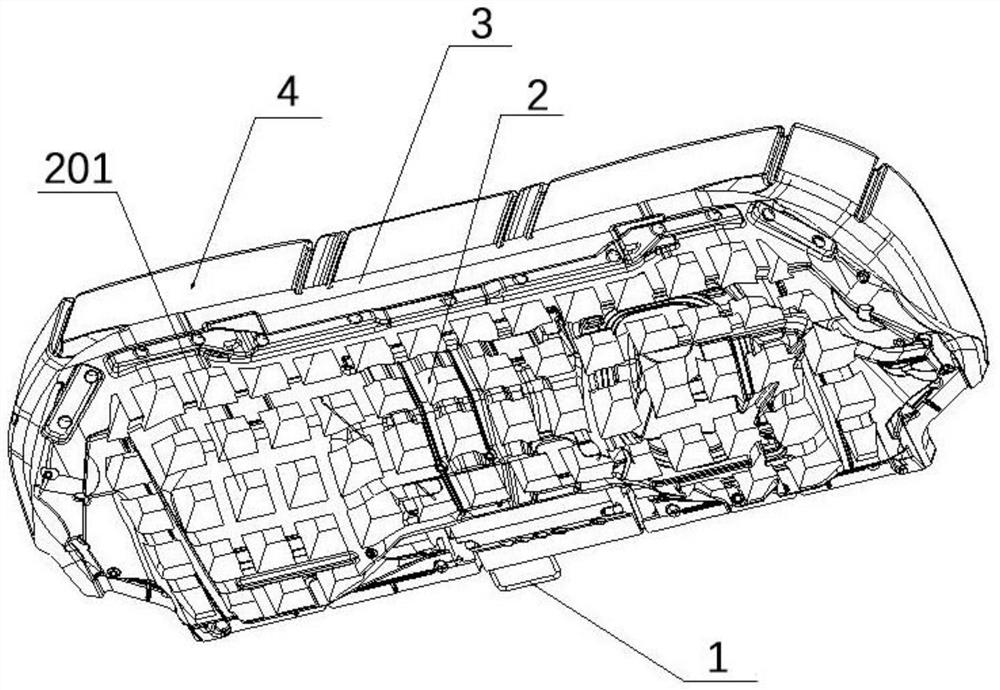

[0031] A seat cushion structure, characterized by: comprising a skeleton 1, a foam layer 2, a PUR foam layer 3 and a decorative fabric layer 4;

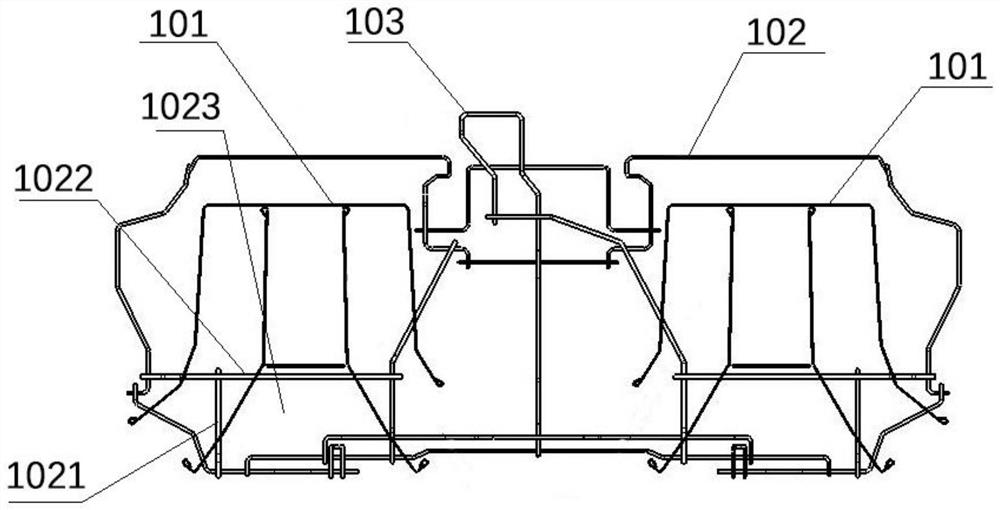

[0032] The skeleton 1 includes an outer skeleton 101, an inner skeleton 102 and a connecting skeleton 103;

[0033] The outer frame 101, the inner frame 102 and the connecting frame 103 are all welded from metal strips;

[0034] Wherein the outer outline skeleton 101 and the inner skeleton 102 are parallel and not in contact with each other, and the inner skeleton 102 and the connecting skeleton 103 are connected by welding;

[0035] The area surrounded by the ribs I1021, ribs II1022 of the internal frame 102 and the frame of the internal frame 102 is the reinforced area 1023 of the internal frame 102;

[0036] The frame 1 is wrapped with a foam layer 2, wherein the frame 1 is seamlessly connected with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com