Reconstituted tobacco finished product boxing device and reconstituted tobacco finished product boxing method

A technology for reconstituted tobacco leaves and finished products, which is applied in the boxing of finished reconstituted tobacco leaves and the field of boxing devices for finished reconstituted tobacco leaves, and can solve problems that have not been considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

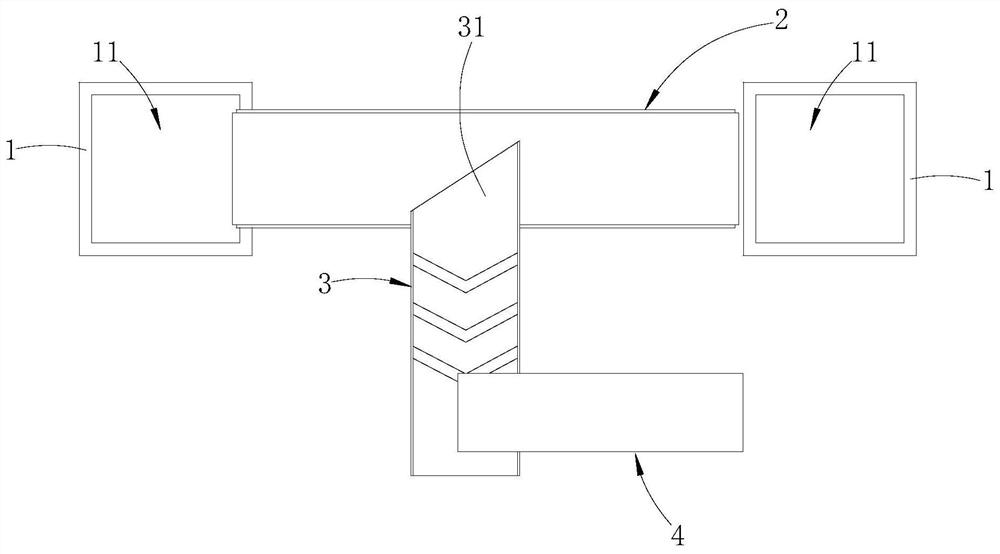

[0028] Such as Figures 1 to 3 shown

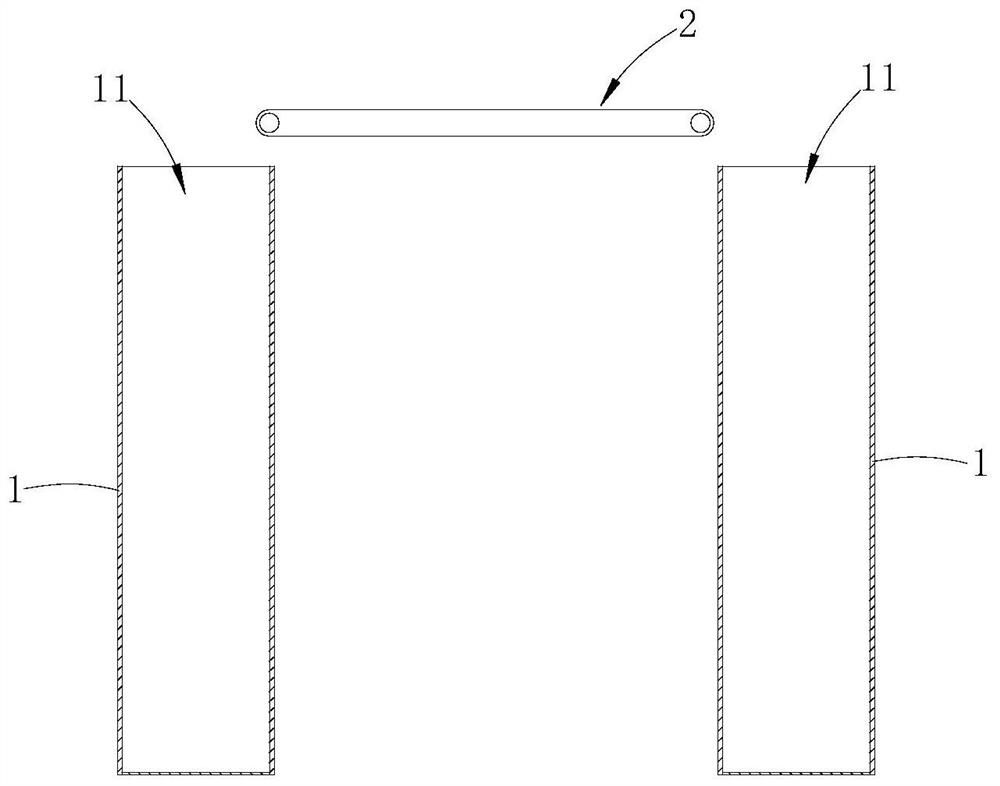

[0029] The reconstituted tobacco finished product boxing device includes a bidirectional reciprocating conveyor belt 2, a weighing conveyor belt 4, a vibrating conveyor 3 and two pre-pressing balers hoppers 1.

[0030] The two pre-pressing baler material boxes 1 are arranged horizontally in turn, and the upper end of the pre-pressing baler material box 1 is provided with a feed port 11. The moving tracks of the ends on both sides of the reciprocating conveyor belt 2 pass through the feeding ports 11 of the two pre-pressing baler bins 1 respectively.

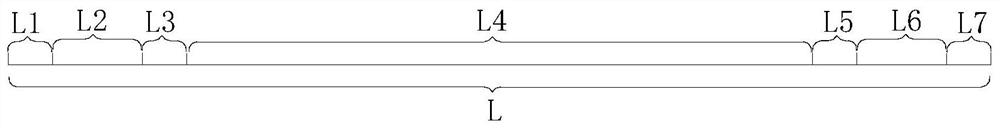

[0031] The two-way reciprocating conveyor belt 2 is arranged on the upper side of the two pre-pressing baler bins 1, and the two-way reciprocating conveyor belt 2 reciprocates horizontally in the left and right directions, and the upper belt of the two-way reciprocating conveyor belt 2 constitutes the first conveyor for transporting tobacco materials. Channel, the moving trajectory of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com