Suction mechanism

A technology of suction mechanism and shrapnel, which is applied to conveyor objects, transportation and packaging, etc., can solve problems such as affecting the product suction yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

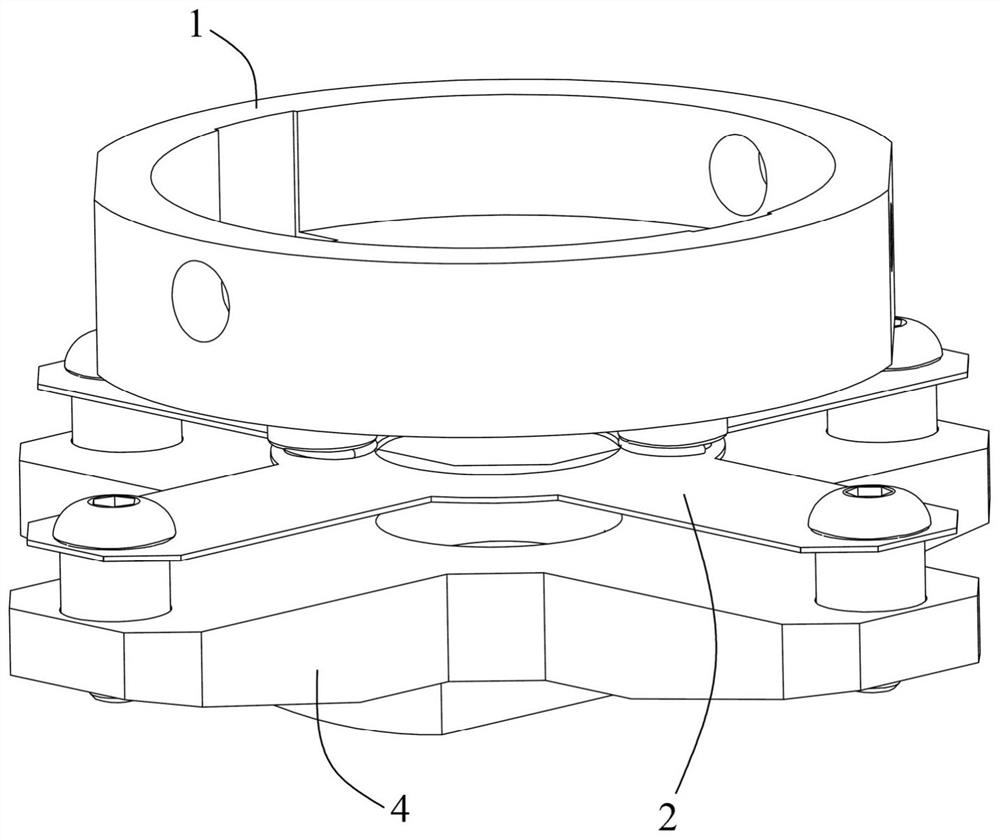

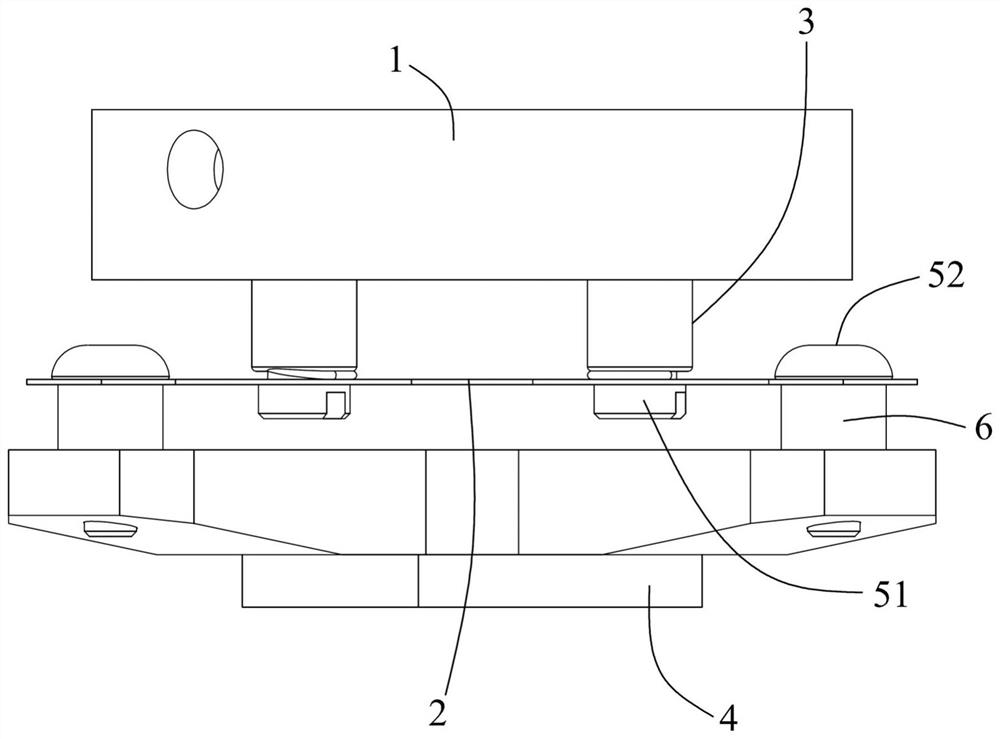

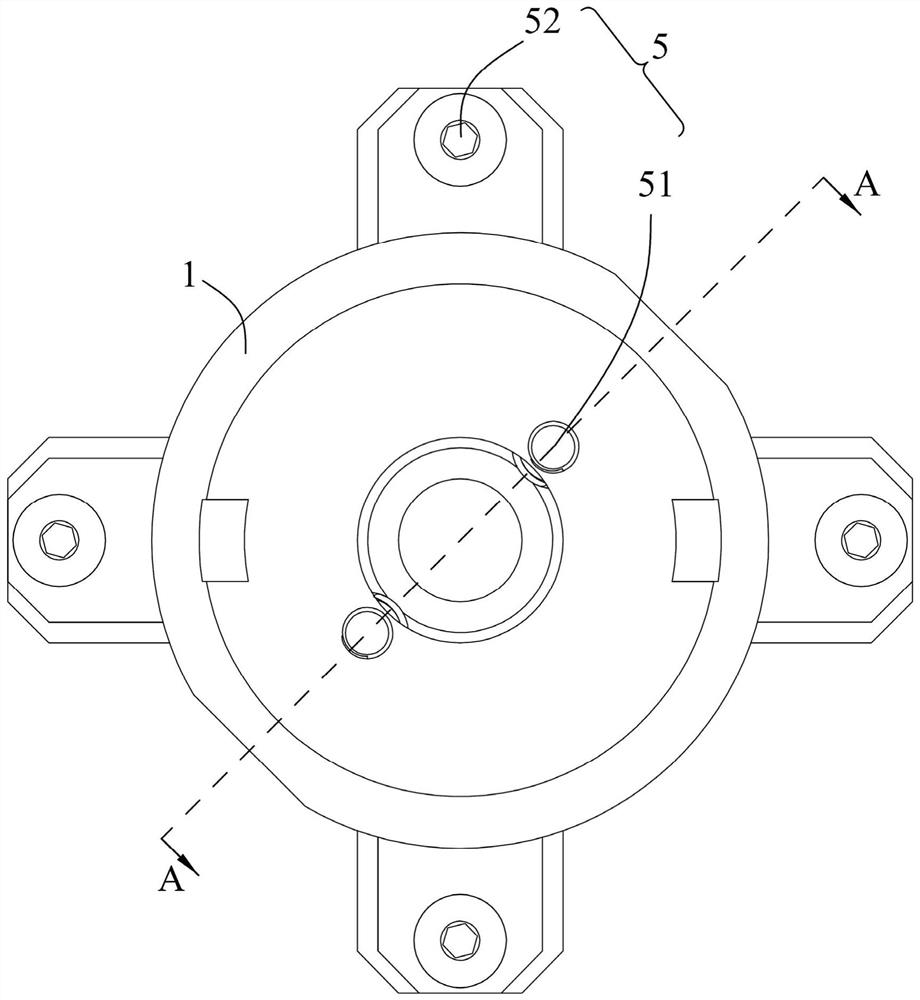

[0035] Please refer to Figure 1 to Figure 12 , a suction mechanism, comprising a device connector 1 , an elastic sheet 2 and a suction head 4 , the elastic sheet 2 is arranged between the device connector 1 and the suction head 4 . The edge of the elastic sheet 2 and the top of the suction head 4 are spaced apart and fixedly connected, and the middle part of the elastic sheet 2 and the bottom of the device connector 1 are either fixedly connected or floatingly connected. .

[0036] exist Figure 1 to Figure 12 In Embodiment 1 and Embodiment 2 of the present invention shown, the elastic piece 2 includes a central substrate 21 and a plurality of blades 22 radially extending from the outer periphery of the central substrate 21 . The number of the blades 22 is not limited, and can be made into two or three blades or even more, such as the two blades, that is, the shrapnel 2 is a long strip, and the lateral elasticity of the two blades is small, the amount of deformation is smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com