Bottom layer plastering gypsum and preparation method thereof

A plastering gypsum and bottom layer technology, applied in the field of bottom plastering gypsum and its preparation, can solve the problems such as the inconspicuous retarding effect, achieve the effect of reducing the consumption of natural resources, alleviating the extreme shortage, and improving the level of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The bottom plastering gypsum of the present embodiment is prepared by the following method:

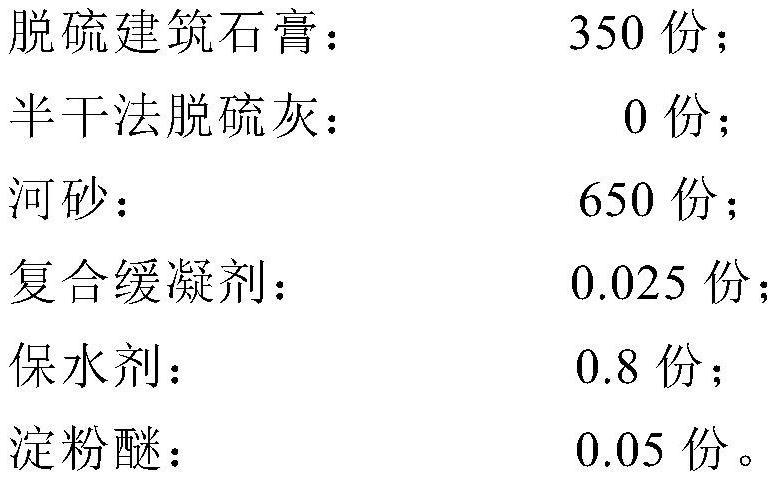

[0071] (1) Batching: take raw material and admixture according to the component of plastering gypsum at the bottom, wherein the components of raw material and admixture all weigh by weight in 1kg of plastering gypsum at the bottom:

[0072]

[0073] Wherein the above raw materials do not use semi-dry desulfurization ash, then the protein retarder can be used alone in the corresponding composite retarder; the composite retarder can also use protein retarder and carboxylic acid (salt) group containing The organic retarder is chemically prepared.

[0074] (2) Admixture configuration: Add the composite retarder, water retaining agent, and starch ether weighed in step (1) into the mixer for pre-mixing for 2 to 3 minutes, so that each component is mixed evenly to obtain the admixture;

[0075] (3) Bottom plastering gypsum configuration: according to the order of feeding, add the ...

Embodiment 2

[0079] The bottom plastering gypsum of the present embodiment is prepared by the following method:

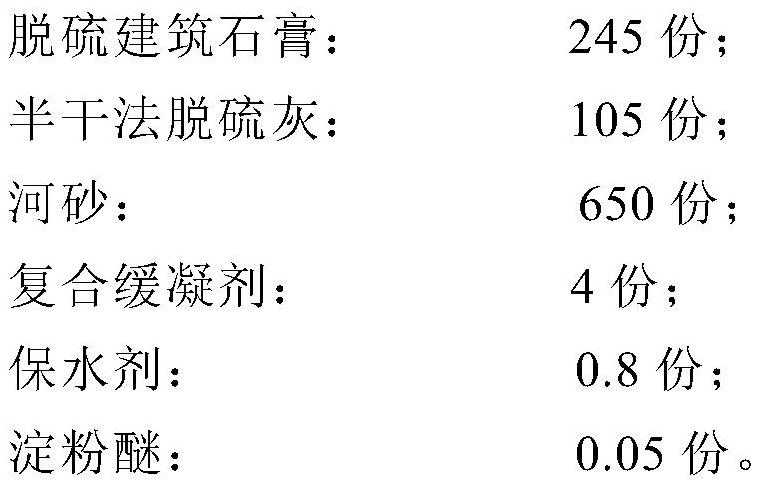

[0080] (1) batching: take raw material and admixture according to the component of bottom plastering gypsum, wherein the component of raw material and admixture all weighs by containing following weight portion in 1kg bottom plastering gypsum:

[0081]

[0082] Among them, semi-dry desulfurization ash is used in the above-mentioned raw materials. In order to ensure the performance of the final plastering gypsum, the corresponding composite retarder needs to be chemically composed of a protein retarder and an organic retarder containing a carboxylic acid (salt) group. Prepared.

[0083] (2) Admixture configuration: Add the composite retarder, water retaining agent, and starch ether weighed in step (1) into the mixer for pre-mixing for 2 to 3 minutes, so that each component is mixed evenly to obtain the admixture;

[0084] (3) Bottom plastering gypsum configuration: Add the d...

Embodiment 3

[0088] The bottom plastering gypsum of the present embodiment is prepared by the following method:

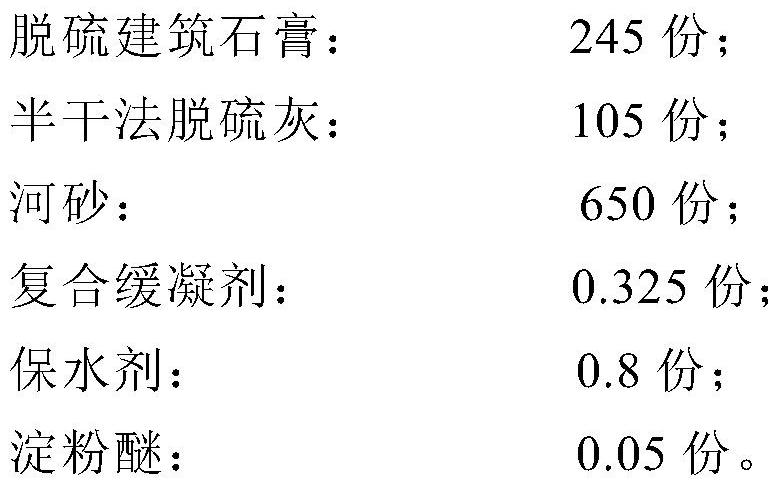

[0089] (1) batching: take raw material and admixture according to the component of bottom plastering gypsum, wherein the component of raw material and admixture all weighs by containing following weight portion in 1kg bottom plastering gypsum:

[0090]

[0091] Among them, semi-dry desulfurization ash is used in the above-mentioned raw materials. In order to ensure the performance of the final plastering gypsum, the corresponding composite retarder needs to be chemically composed of a protein retarder and an organic retarder containing a carboxylic acid (salt) group. Prepared.

[0092] (2) Admixture configuration: Add the composite retarder, water retaining agent, and starch ether weighed in step (1) into the mixer for pre-mixing for 2 to 3 minutes, so that each component is mixed evenly to obtain the admixture;

[0093] (3) Bottom plastering gypsum configuration: Add the d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap