Smelting method of ZL114A alloy

A technology of ZL114A and alloy, which is applied in the field of metal smelting, can solve the problems of difficult gas absorption of the alloy, poor quality of the alloy, and low production efficiency, and achieve the effect of pure alloy liquid, high quality of molten aluminum, and difficult gas absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate a better understanding of the present invention, the following examples are used to illustrate, and these examples belong to the protection scope of the present invention, but do not limit the protection scope of the present invention.

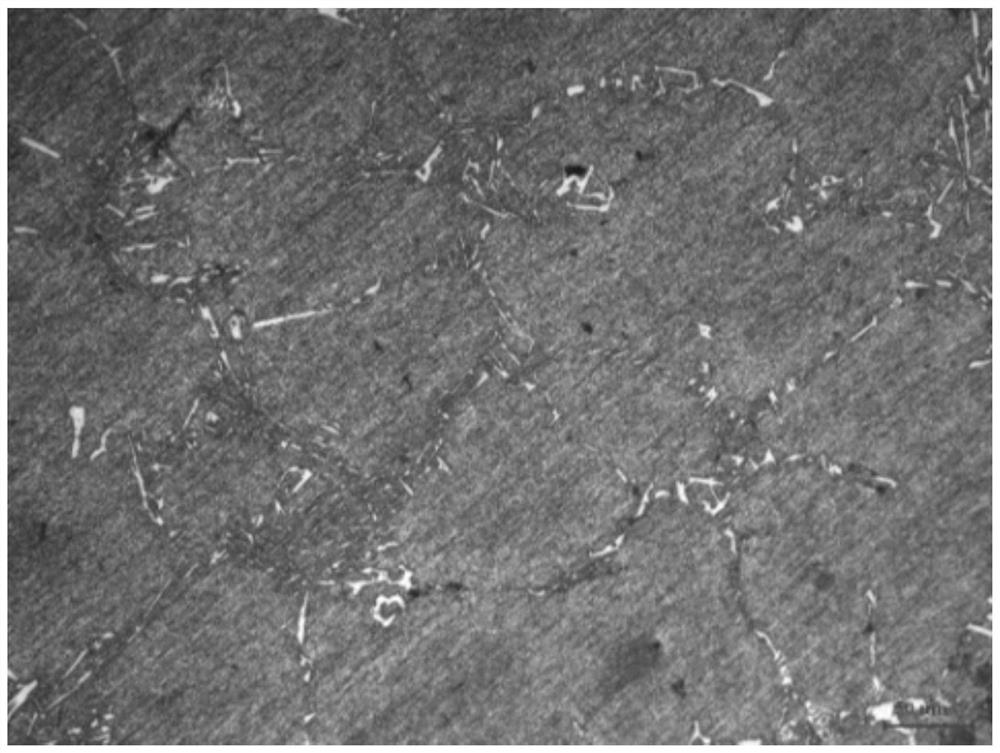

[0033] like Figure 1-2 As shown, the present invention proposes a kind of smelting method of ZL114A alloy, comprises the steps:

[0034] S1, adding high-purity aluminum ingots to melt;

[0035] S2, adding high-purity Si at 700-800°C;

[0036] S3, master alloy modification and refinement;

[0037] S4. Refining by high-purity argon rotary blowing method;

[0038] S5, pouring after standing still.

[0039] In this example, in S3, the alloys added in modification and refinement include imported AlTiB wire, Al-Sb inter-addition alloy and Al-Te inter-addition alloy.

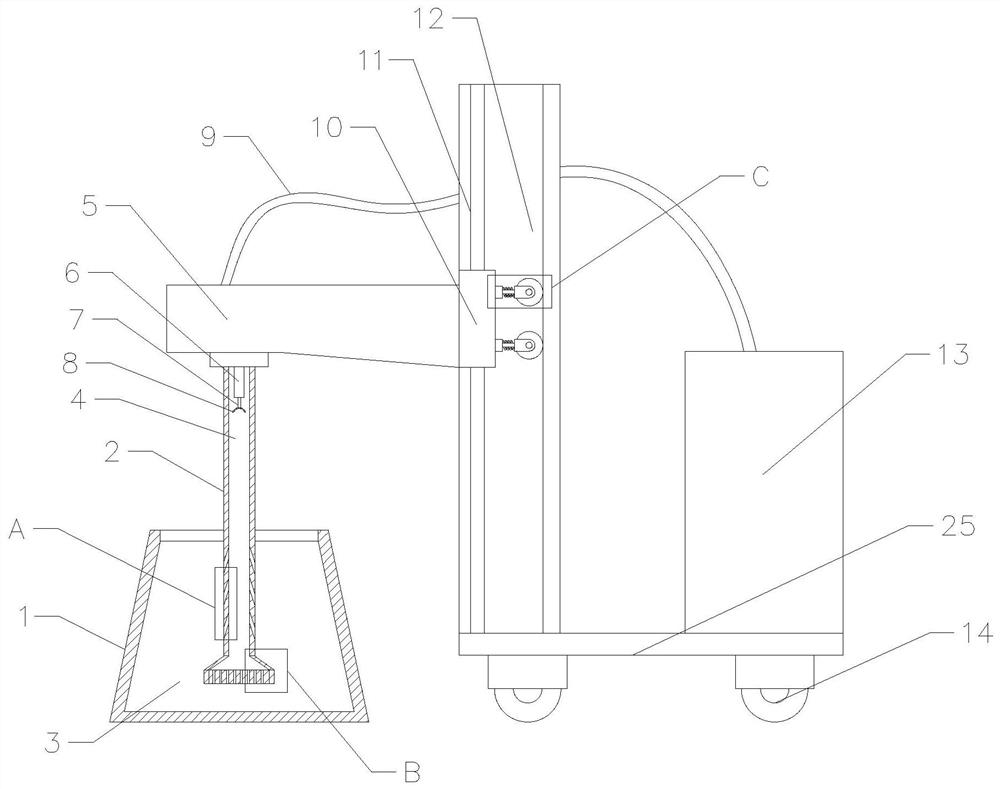

[0040] In this embodiment, as shown in Figure S4, the rotary injection device used in the rotary injection method includes a furnace body 1 for refi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com