Capillary tube immersion type heat exchanger

A capillary and heat exchanger technology, applied in the field of capillary immersion heat exchangers, can solve problems such as poor heat transfer effect, severe frosting or freezing, and inability to transfer heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

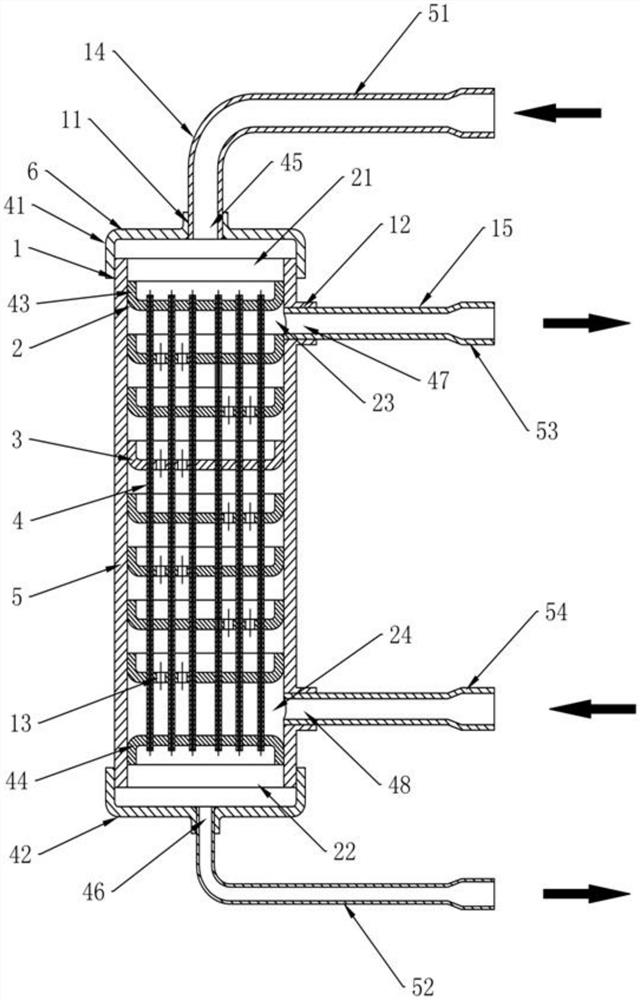

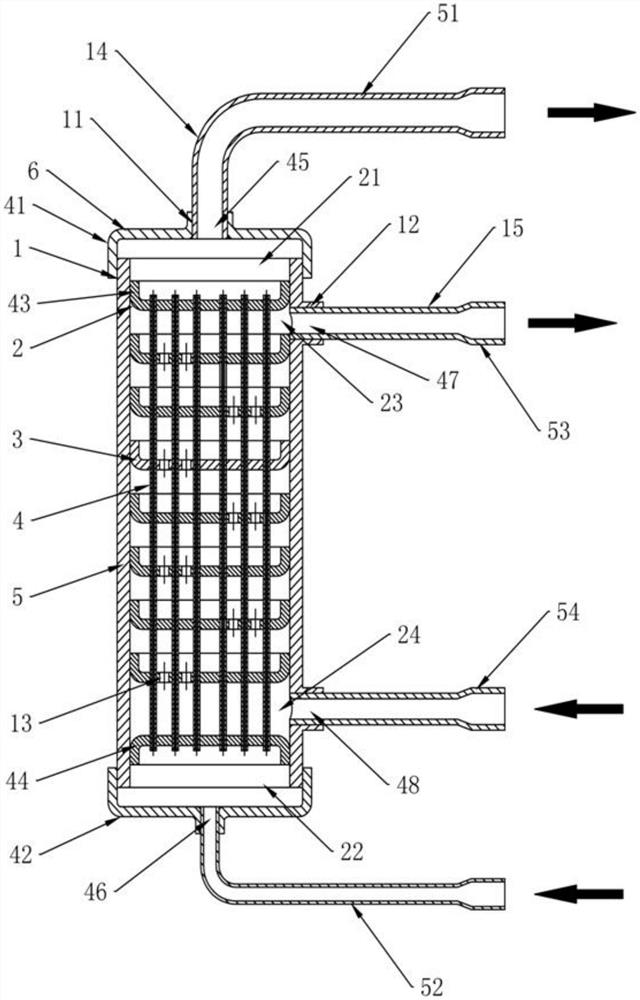

[0035] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 5 As shown, the capillary immersion heat exchanger also includes: two first connecting pipes 14 and two second connecting pipes 15, the two first connecting pipes 14 are respectively connected to the two first ports 11, and the two second connecting pipes 15 are respectively connected to the two second ports. The two first connecting pipes 14 communicate with the first space 21 and the second space 22 respectively, and the two second connecting pipes 15 communicate with the third space 23 and the fourth space 24 respectively.

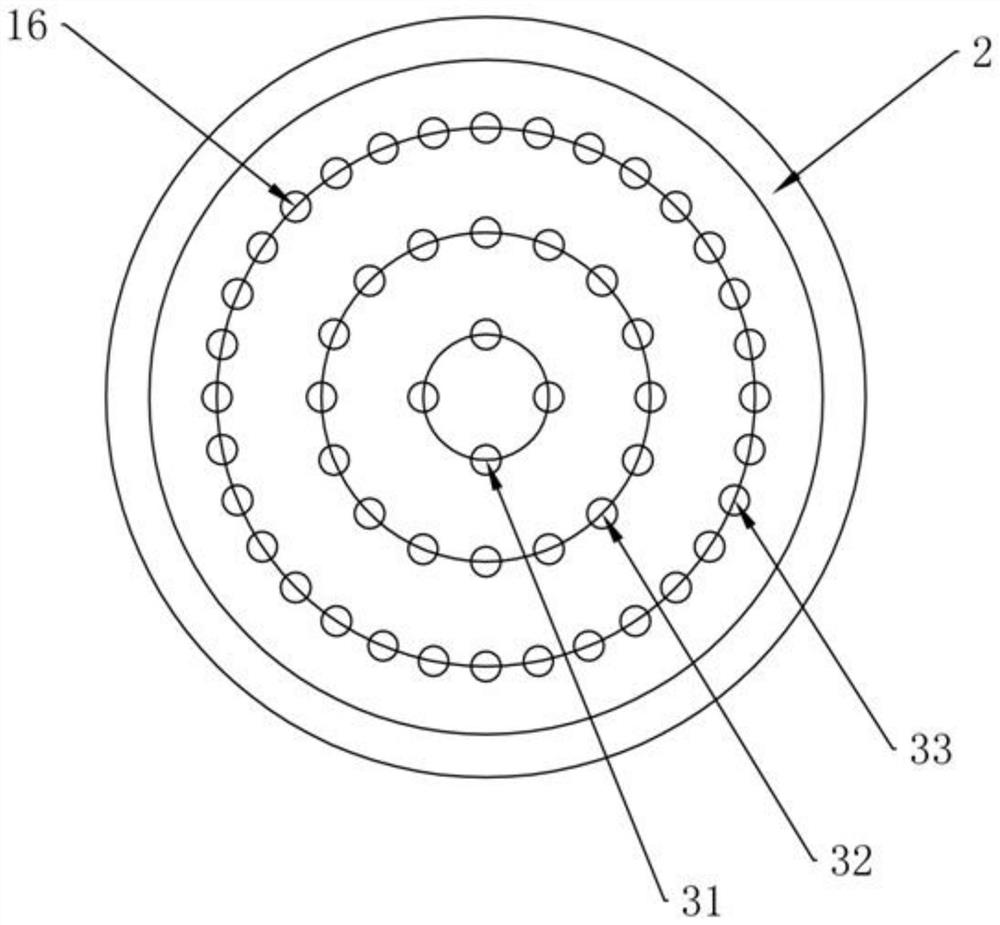

[0036]In a further embodiment of the present invention, the casing 1 includes: a housing 5 and two outer end covers 6, the housing 5 is vertically arranged, the two outer end covers 6 are respectively arranged at two ends of the housing 5, and the two inner end covers 2 They are respectively arranged at both ends of the casing 5 , and a plurality of b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com