Internal spraying water film type heat exchange system

A heat exchange system, spraying water technology, applied in the direction of heat exchange equipment, heat exchanger type, heat exchanger shell, etc., can solve the problems of severe frost or icing, poor cooling effect, poor heat exchange effect, etc. To achieve the effect of short heat exchange process, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

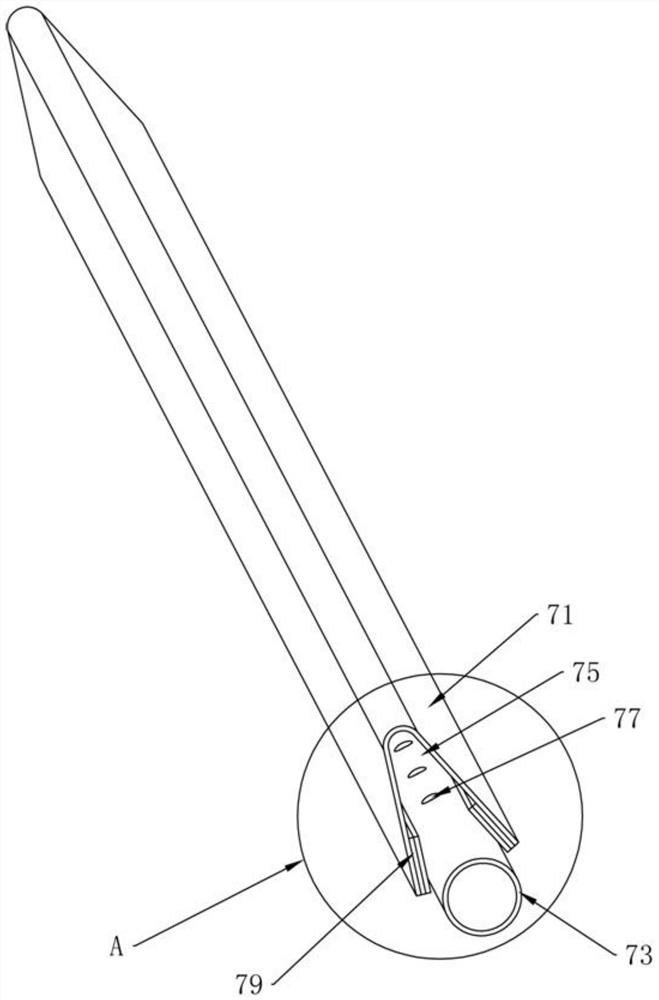

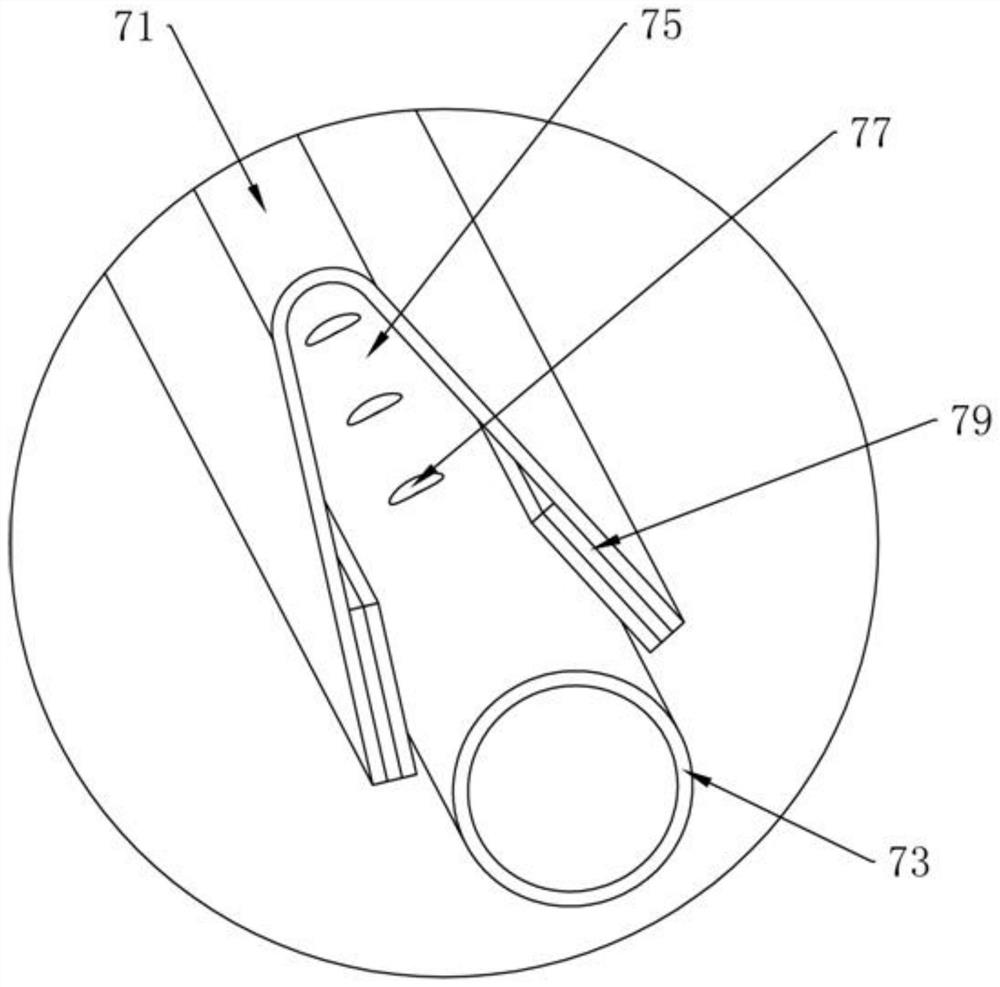

[0053] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 9 As shown, each spray assembly 7 also includes: a support pipe 81, the support pipe 81 is arranged on the inner side of the spray inner plate 72, the support pipe 81 is located directly below the inner spray pipe 73, the top of the support pipe 81 and the baffle plate 74 connections.

[0054] Further, as a preferred embodiment, the spray outer plate 71 , the spray inner plate 72 , the inner spray pipe 73 and the support pipe 81 are all arranged vertically.

[0055] Preferably, both sides of the inner side of the upper end of the spray outer plate 71 are respectively connected to the side walls of the inner spray pipe 73 through at least one spacer 79, and the inner sides of the lower end of the spray outer plate 71 are respectively connected to the support pipe 81. side wall connections.

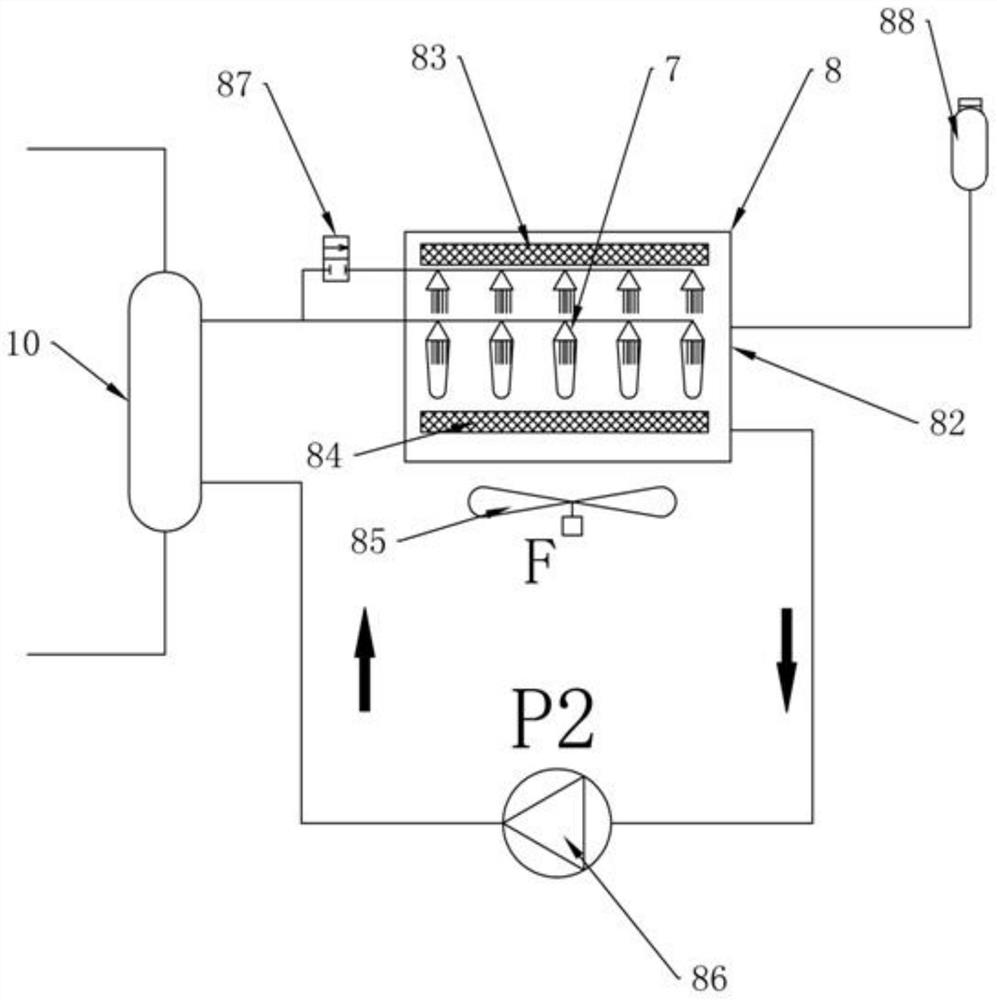

[0056] In a further embodiment of the present invention, the spray heat exchange me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com