Shaped capillary channel heat exchanger

A heat exchanger and capillary technology, applied in indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problems of large volume and weight of shell and tube heat exchangers, difficult maintenance and repair, and improve safety. Reliable performance, reduced volume and weight, and increased heat transfer coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

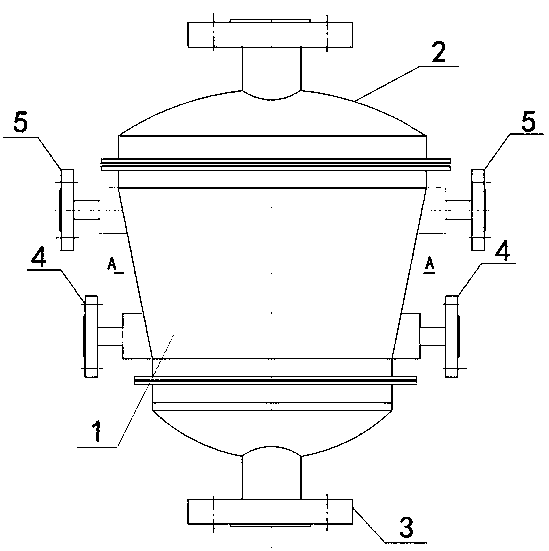

[0028] By the attachment figure 1 , 2 Shown: the heat exchanger includes a core 1, an upper header connecting flange arranged at the upper end of the core 1 and connecting the hot fluid inlet pipe 2, a lower header connecting method arranged at the lower end of the core 1 and connecting the hot fluid outlet pipe The flange 3 is arranged on the left and right sides of the core 1 at least one header connecting flange 4, 5 connecting the inlet and outlet pipes of the cooling medium, and the air inlet area of the upper header connecting flange 2 is larger than that of the lower header connecting method Lan 3 outlet area.

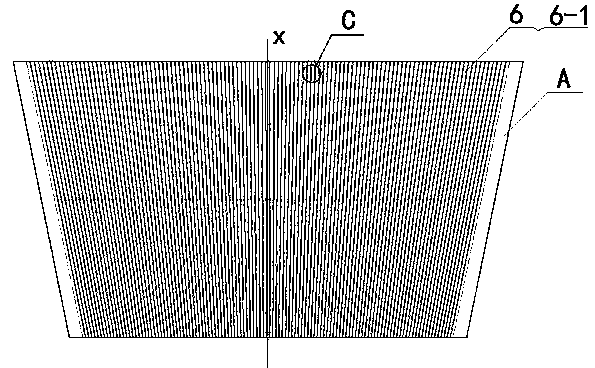

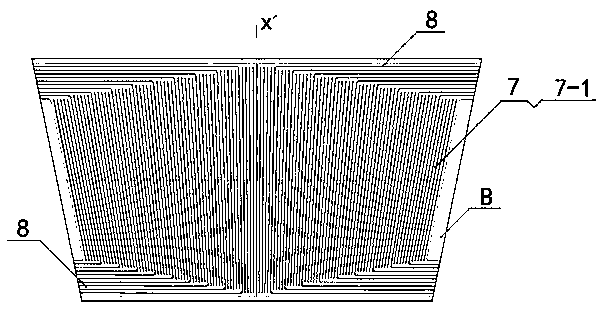

[0029] By the attachment figure 2 , 3 , 4, and 5: The core 1 is composed of a plurality of heat transfer plates A and heat transfer plates B which are alternately stacked in sequence with the top plate by diffusion welding. The heat transfer plate A adopts chemical etching and other processes on its side The surface is processed with a first variable cross-sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com