Test chamber and method for testing a test material

A test material and test chamber technology, applied in the field of test chambers, can solve problems such as damage to the flexible film, endangering the test chamber, damage to the test space of the test material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

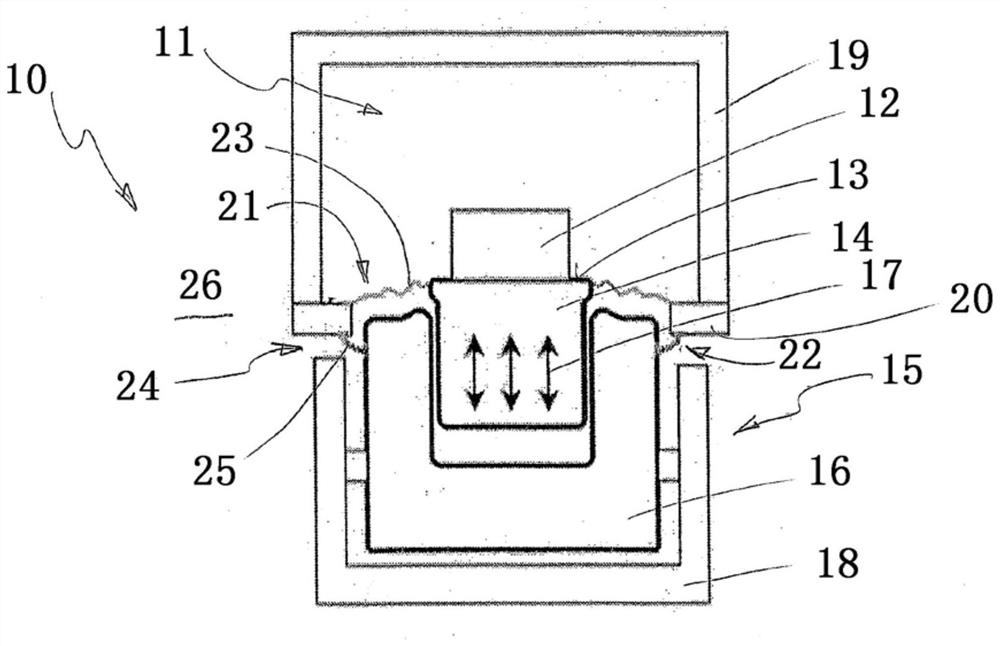

[0033] figure 1 A schematic cross-sectional view of a test chamber 10 with a test space 11 in which a test material 12 is arranged is shown. The test material 12 may be an accumulator or battery and can be exposed to defined temperature variations within the test space 11 . The test material 12 is rigidly positioned on the contact surface 13 of the vibrator 14 of the vibration device 15 such that the test material 12 can be exposed to vibrations of defined frequency and amplitude. The vibration device 15 also comprises a housing 16 towards which the vibrator 14 is movable relative to the direction of the arrow 17 . The vibrating device 15 also includes a base 18 on which the housing 16 is mounted to dampen vibrations.

[0034] The test space 11 is formed by temperature insulating walls 19 , 20 , and an opening 21 is formed in the wall 20 through which the vibration device 15 protrudes into the test space 11 . The gap 22 between the wall 20 and the vibration device 15 is sea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap