Method for evaluating shale hydration inhibition capability of water-based drilling fluid

A water-based drilling fluid and mud shale hydration technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of easily reducing the accuracy of test results, too much influence of stirring time and stirring rate, etc., to prevent well wall instability, reduce drilling costs, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical solutions and advantages of the present invention more clearly, the embodiments of the present invention will be further described in detail below.

[0031] The embodiment of the present invention provides a method of evaluating a water-based drilling fluid inhibiting the hydration capability of mud sheet, including the following steps:

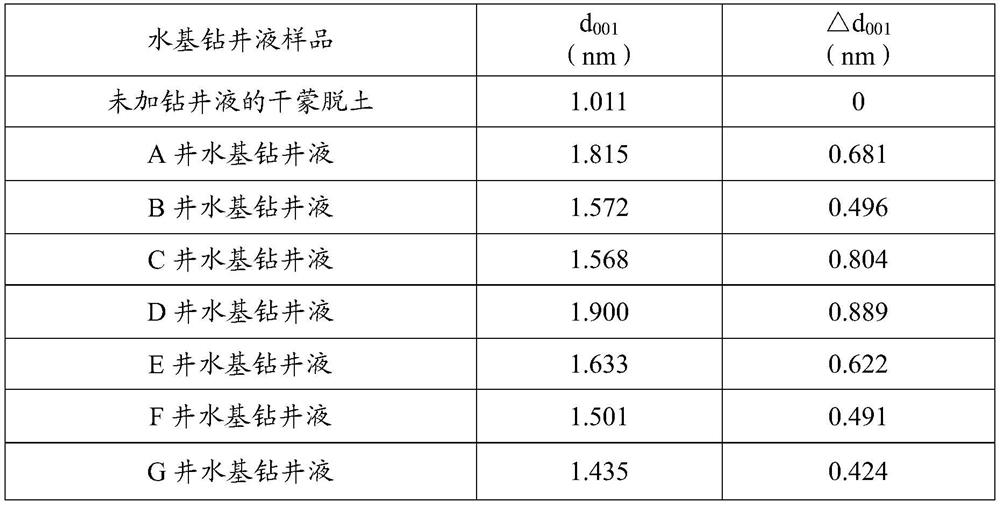

[0032] Provide dry shale samples, tested dry shale samples of lattice layer spacing D 001 .

[0033] Add a quantified dry shale sample and quantitative water-based drilling fluid to be evaluated in the reaction flask, and the first set time is stirred at a set temperature, then the second set time is centrifuged.

[0034] Collect shale sample hydrated precipitate, test the lattice spacing of shale sample precipitates D 001 .

[0035] Gets the lattice layer spacing D of shale sample hydrated precipitate D 001 Layer spacing D with dry shale samples 001 Difference △ D 001 .

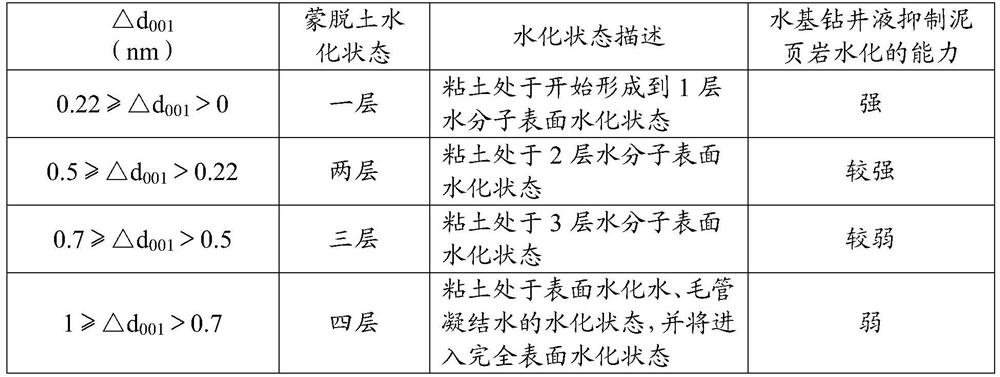

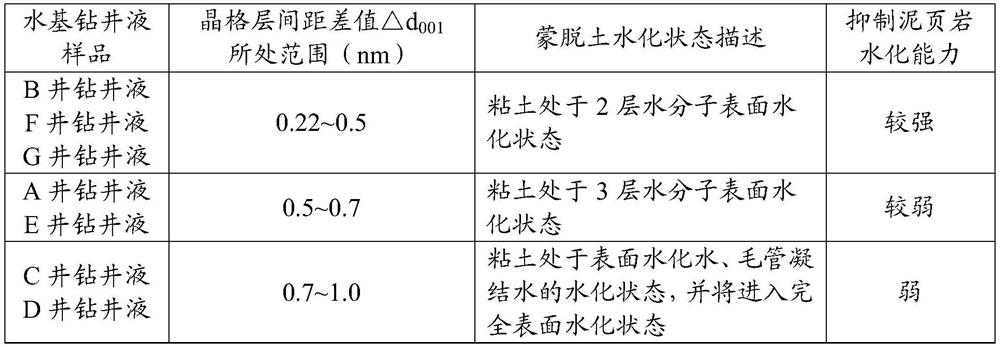

[0036] Put the difference △ D 001 Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com