Welding, wiring and light splitting three-in-one ODF distribution box

A three-in-one, distribution box technology, applied in the field of optical fiber equipment, can solve problems such as difficult maintenance and management, difficult line expansion, and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

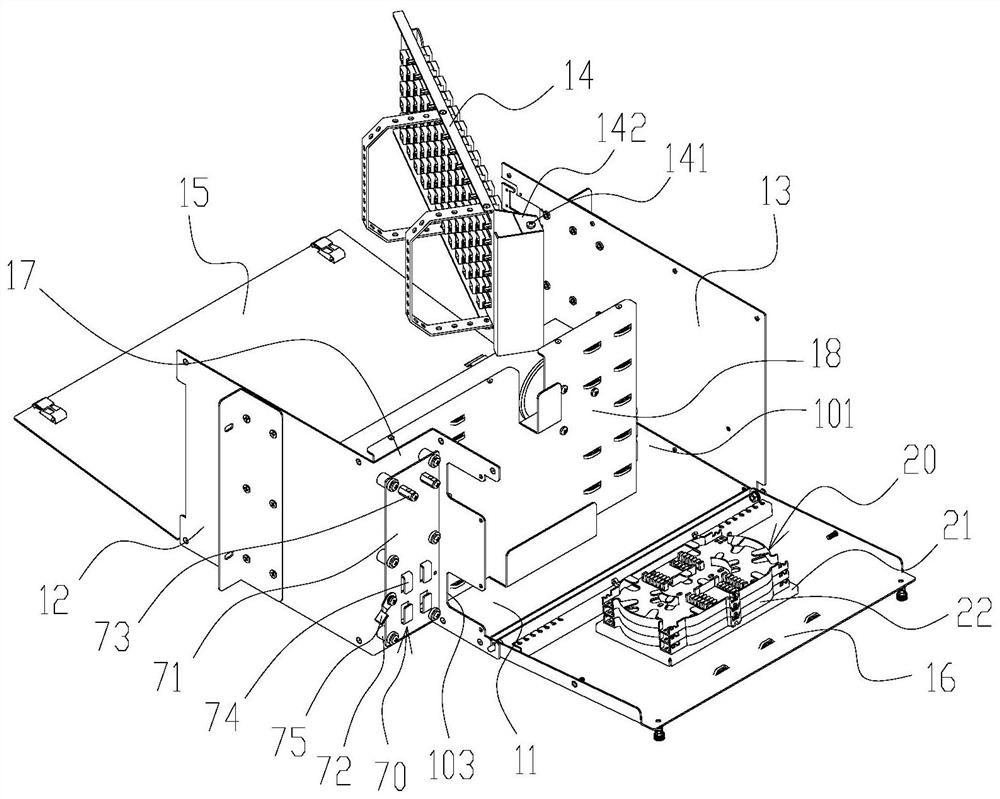

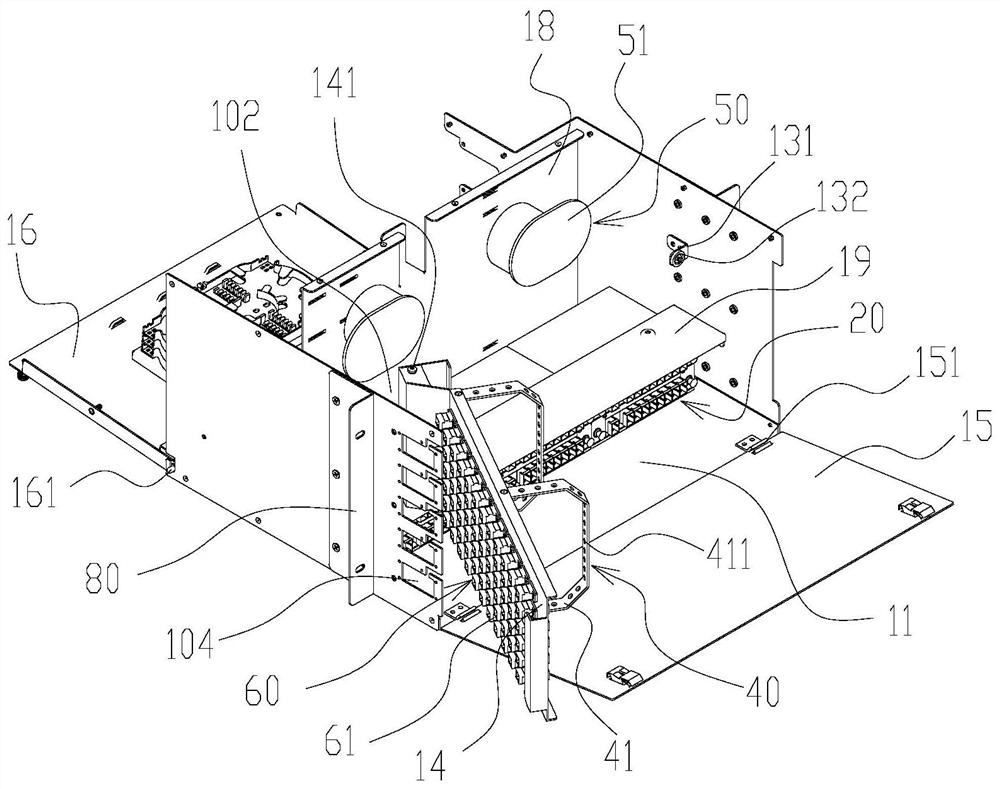

[0023] refer to figure 1 , figure 2 , this embodiment provides a three-in-one ODF distribution box with welding, wiring, and light splitting, including a box body, and the box body includes a bottom plate 11, a left side plate 12, a right side plate 13, a top plate, a front door panel 15, and a rear door panel 16 and the rear fixed plate 17, the box is provided with a vertical first partition 18 and a horizontal second partition 19; the left side of the first partition 18 is connected with the left side plate 12, and the A first optical cable channel 101 is provided, a first accommodating cavity is provided between the first partition 18 and the rear door panel 16, and a fiber fusion unit 20 is arranged in the first accommodating cavity, and the fiber fusion unit 20 is fixed on the rear door panel 16 ; The second partition 19 is located on the front side of the first partition 18, a second accommodating chamber is provided between the second partition 19 and the bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com