Method and system for predicting laser thermoforming deformation of hull plate

A technology of hull outer plate and prediction method, applied in biological neural network model, geometric CAD, design optimization/simulation, etc., can solve the problems of slow calculation time and small scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] The processing effect of the laser processing parameters in the laser heating forming of the hull outer plate can be predicted by the thermoelastic finite element model, but when it is applied to calculate the processing deformation effect of large-size plates and complex processing paths, there is a small scope of application. , Calculation time is slow and so on. The invention provides a forming effect prediction method combined with neural network and inherent strain method simulation, which can quickly solve the deformation results of large-size plates and complex paths.

[0069] In order to achieve the above object, the present invention provides a method for predicting molding effect combined with neural network and inherent strain method simulation, the method comprising the following steps:

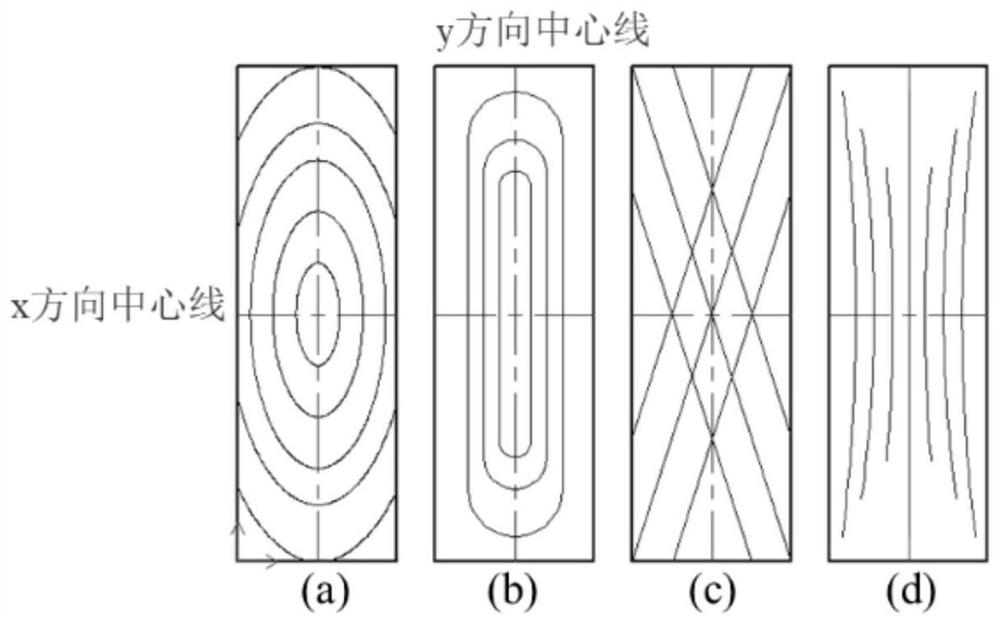

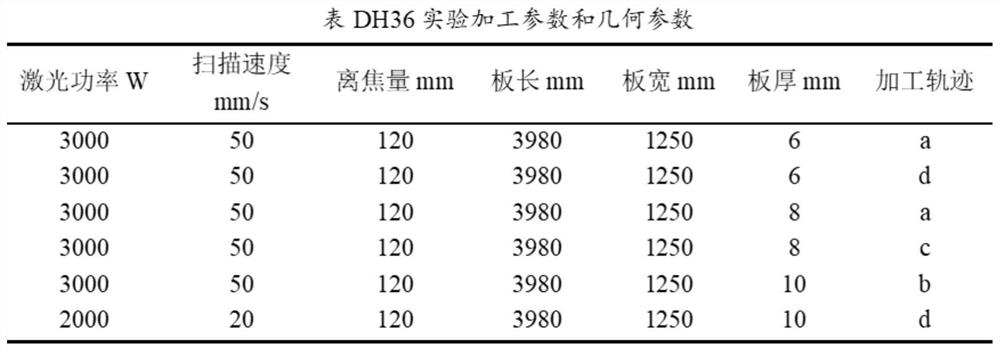

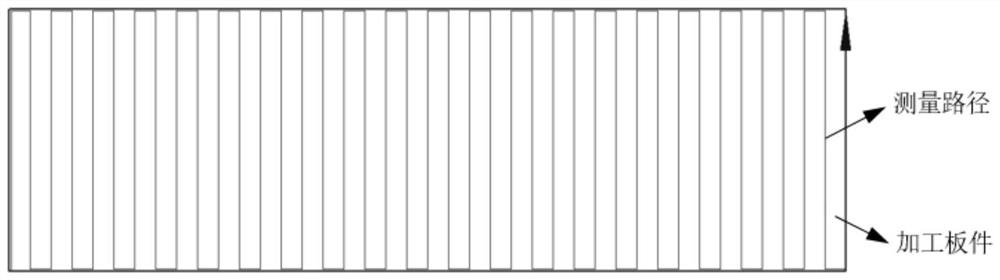

[0070] Step 1: First, establish a reasonable process window for the heat source parameters and plate parameters based on the analysis of the actual processing process; then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com