Efficient neutron conversion screen

A neutron conversion screen, neutron technology, applied in the direction of conversion screen, photography technology, optics, etc., can solve the problems of long imaging time, weak light, unfavorable formation of clear images, etc., and achieve the effect of shortening the clear image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

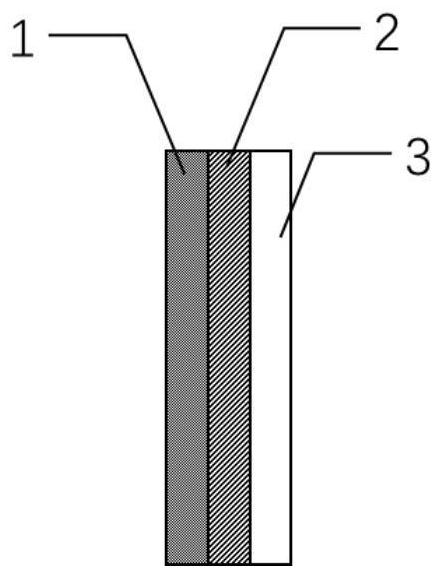

[0016] This case is an efficient neutron conversion screen suitable for heat neutron imaging. The design principle is to increase the number of neutron reached by the fluorescent layer by multiplying the neutron reacted by the neutron reaching the conversion screen. The neutron conversion screen is composed of neutron multiplier layer 1, the fluorescent layer 2, and the high purity hard aluminum plate 3, and the fluorescent layer 2 is coated with a uniformly applied manner on high purity hard aluminum plate 3, neutral multiplier 1 to uniformly apply. Compared with the fluorescent layer 2, such as figure 1 Indicated.

[0017] The neutronic multiplication layer 1 is placed in the neutron multiplication material, and the multiplication material selects a fission material such as U235, PU239 or TH233, such as for U235, using U235, with a neutron, and ambigulent reaction reaction releases 2.45 neutrons, achieving effective neutrons. Multiplication;

[0018] The fluorescent layer 2 cons...

Embodiment 2

[0021] This case is an efficient neutron conversion screen suitable for fast neutron imaging. The design principle is to multiply by reacting the neutron reaching the conversion screen by (N, 2N) or (N, 3N). The number of neutron reached the fluorescent layer. The neutron conversion screen is composed of neutron multiplier layer 1, the fluorescent layer 2, and the high purity hard aluminum plate 3, and the fluorescent layer 2 is coated with a uniformly applied manner on high purity hard aluminum plate 3, neutral multiplier 1 to uniformly apply. Compared with the fluorescent layer 2, such as figure 1 Indicated.

[0022] The neutron multiplier layer 1 is placed in the neutron multiplication material, and the multiplication material is selected from the compound or alloy containing elements such as BE or PB or BI or Zr, such as for BE, when the neutron energy is higher than 1.9 MeV, BE and neutron occur ( N, 2N) Neutron reactions, i.e., absorb a neutron, release 2 neulin, and achieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com