Board Mount Housing Based on Dry Guard Mechanism

A protection mechanism and circuit board technology, which is applied in the direction of casing/cabinet/drawer parts, electrical equipment casing/cabinet/drawer, electrical components, etc. Reduce the service life and other problems, achieve the effect of buffering the damage of the circuit board, prolonging the service life and improving the drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

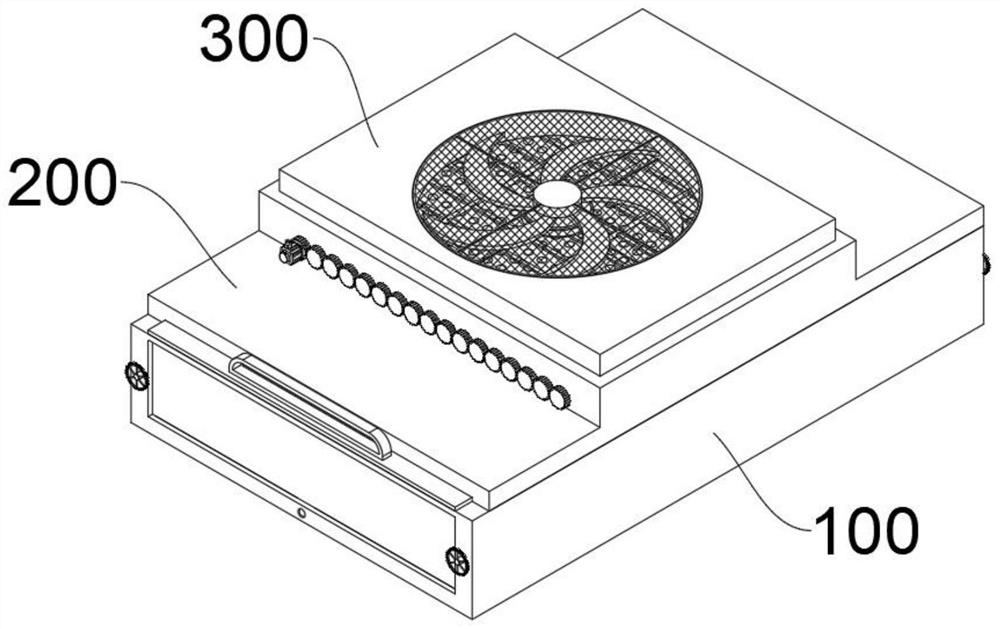

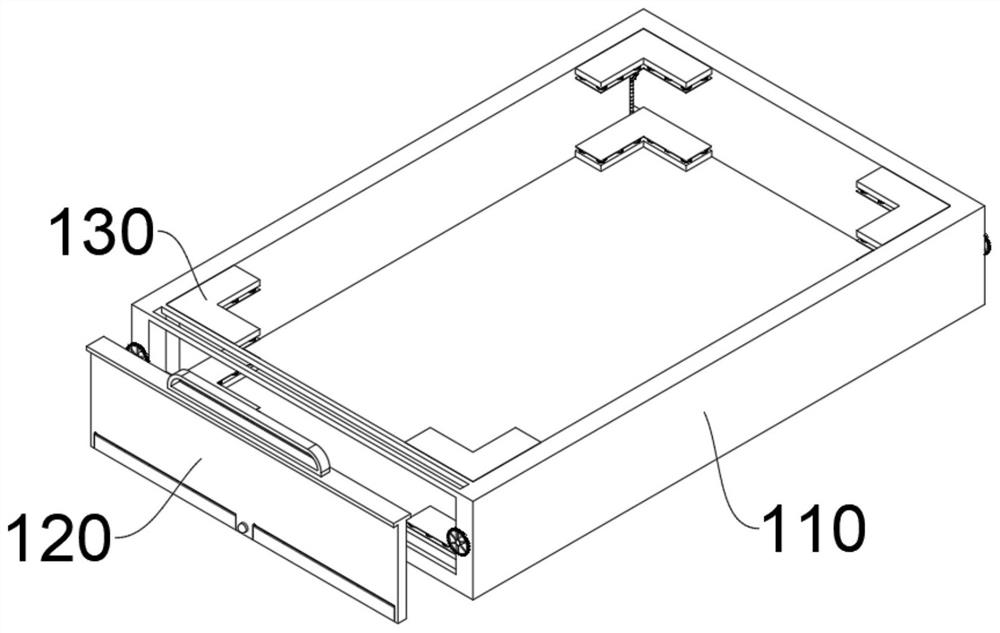

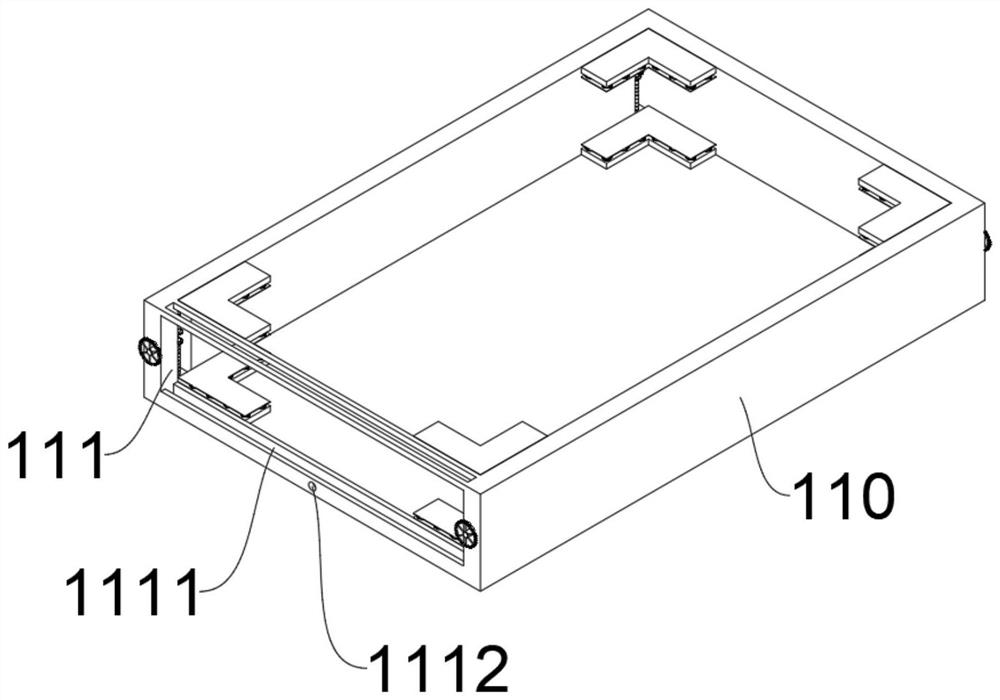

[0046] Install the protective mechanism 100, the installation protective mechanism 100 includes a protective shell 110, and the end of the protective shell 110 is provided with an installation

[0047] When the installation protection mechanism 100 in the present invention is used, the plug board 120 is pulled upward to expose the installation groove 111.

[0048] The drying shielding mechanism 200, the drying shielding mechanism 200 includes a fixing plate 210, and the fixing plate 210 is fixed on the protective shell 110

[0049] The drying shielding mechanism 200 in the present invention adds drying particles 213 to the interior of the cavity 211 to make the

[0050] The ventilation and heat dissipation mechanism 300, the ventilation and heat dissipation mechanism 300 includes a connecting plate 310, and the connecting plate 310 is inserted on the top of the cavity 211

[0053] Specifically, the end of the linkage rod 1124 rotates and extends out of the protective shell 110 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com