Automatic slaughter waiting system

An automatic, constant temperature system technology, applied in slaughtering, slaughtering devices, slaughtering plant equipment, etc., can solve the problems of chicken trucks and forklifts, low efficiency, long waiting time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

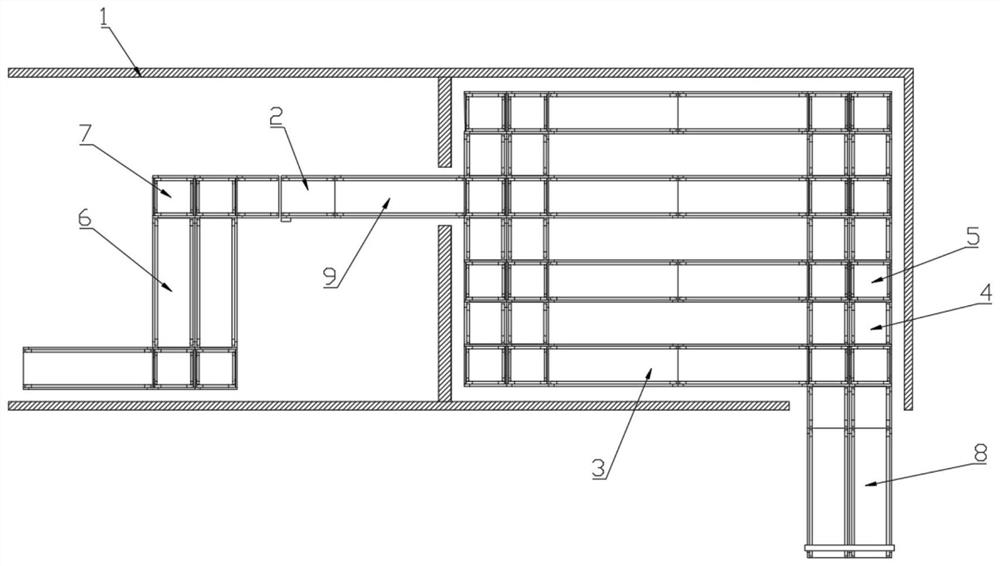

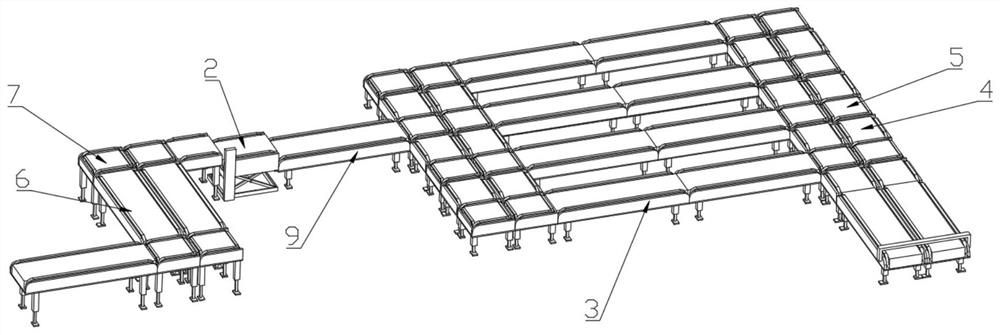

[0030] An automatic slaughtering system, comprising a factory building 1, a conveying track installed in the factory building 1, a scissor lifting track 2, a docking track for slaughtering equipment, and a sensor system arranged on the conveying track, and a constant temperature system is also provided in the factory building 1 , ventilation system and blue light lighting system;

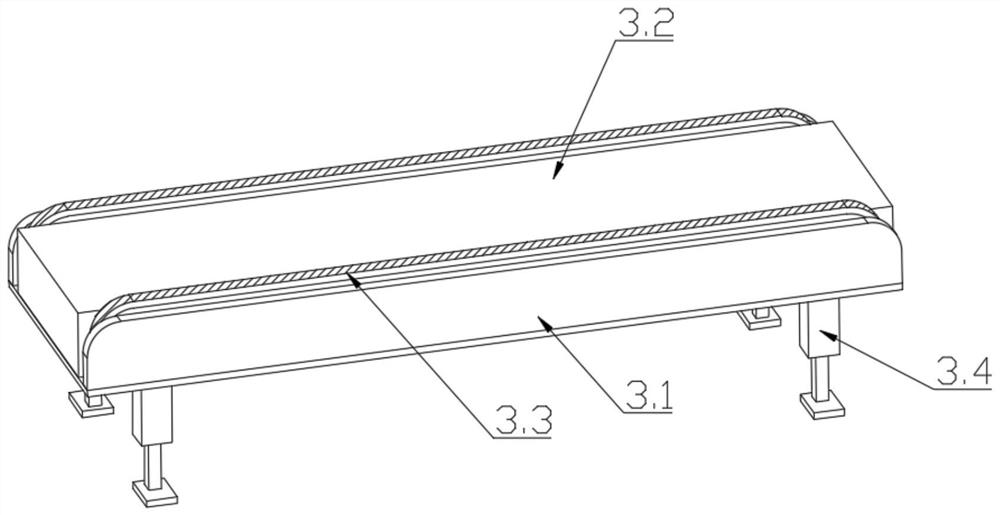

[0031] The conveying track is a grid-shaped track composed of several first conveyors 3, second conveyors 4, and first 90-degree transplanting machines 5. One end of the conveying track corresponds to the entrance of the factory, and the other side passes through the shearing machine. The lifting track 2 is docked with the docking track 3 of the slaughtering equipment, and the docking track 3 of the slaughtering equipment is a multi-bending track made up of several third conveyors 6 and the second 90-degree transplanter 7.

[0032] As a preferred implementation of this embodiment, the conveying trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com