Quantitative raw material extracting and conveying device for production of automobile lubricating oil

A technology of lubricating oil and conveying device for vehicles is applied in the directions of transportation and packaging, lubricating composition, mixer with rotary stirring device, etc. Inability to accurately measure and other problems, to achieve the effect of full and uniform filtration treatment, improve the effect of mixing and preparation, and improve the quality of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

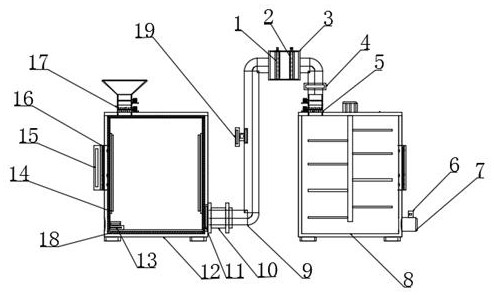

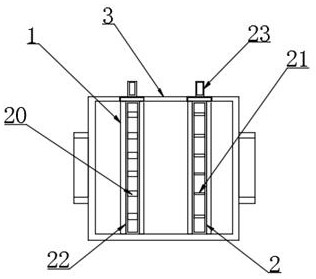

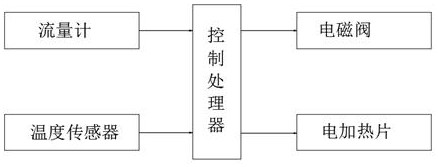

[0020] see Figure 1~3 , in an embodiment of the present invention, a quantitative extraction and conveying device for raw materials used in the production of vehicle lubricating oil, comprising a storage tank 12 and a preparation tank 8 fixedly arranged on one side of the storage tank 12, the side of the bottom end of the storage tank 12 A discharge port 11 is fixedly arranged, a control panel 16 is fixedly arranged on the outer surface of the storage tank 12, an electric heating sheet 14 is fixedly arranged at the position of the inner surface of the storage tank 12, and an inner bottom end position of the storage tank 12 is fixed. A temperature sensor 13 is provided, a control processor 15 is fixedly installed at the inner position of the control panel 16, a liquid suction pump 10 is fixedly installed outside the discharge port 11, and a delivery pipe 9 is fixedly connected to the outlet end of the liquid suction pump 10 to deliver A flow meter 19 is fixedly installed insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com