Metal heat treatment subsequent annealing device

A metal heat treatment and annealing device technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of inconvenient access to metal bars and affect work efficiency, and achieve the effects of novel design, improved work efficiency, and convenient manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

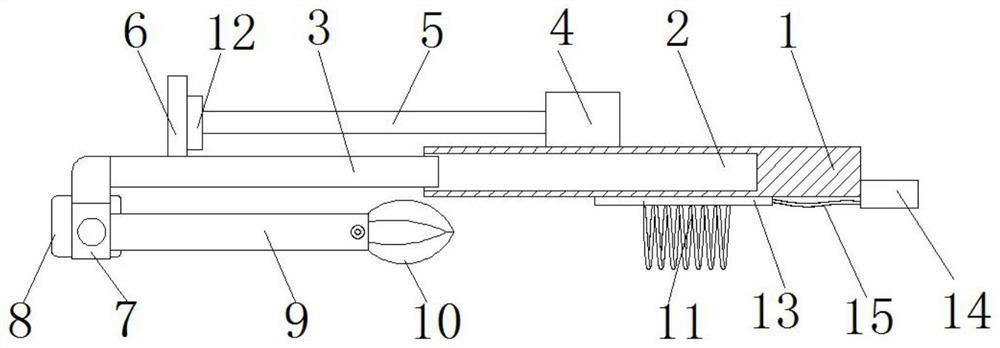

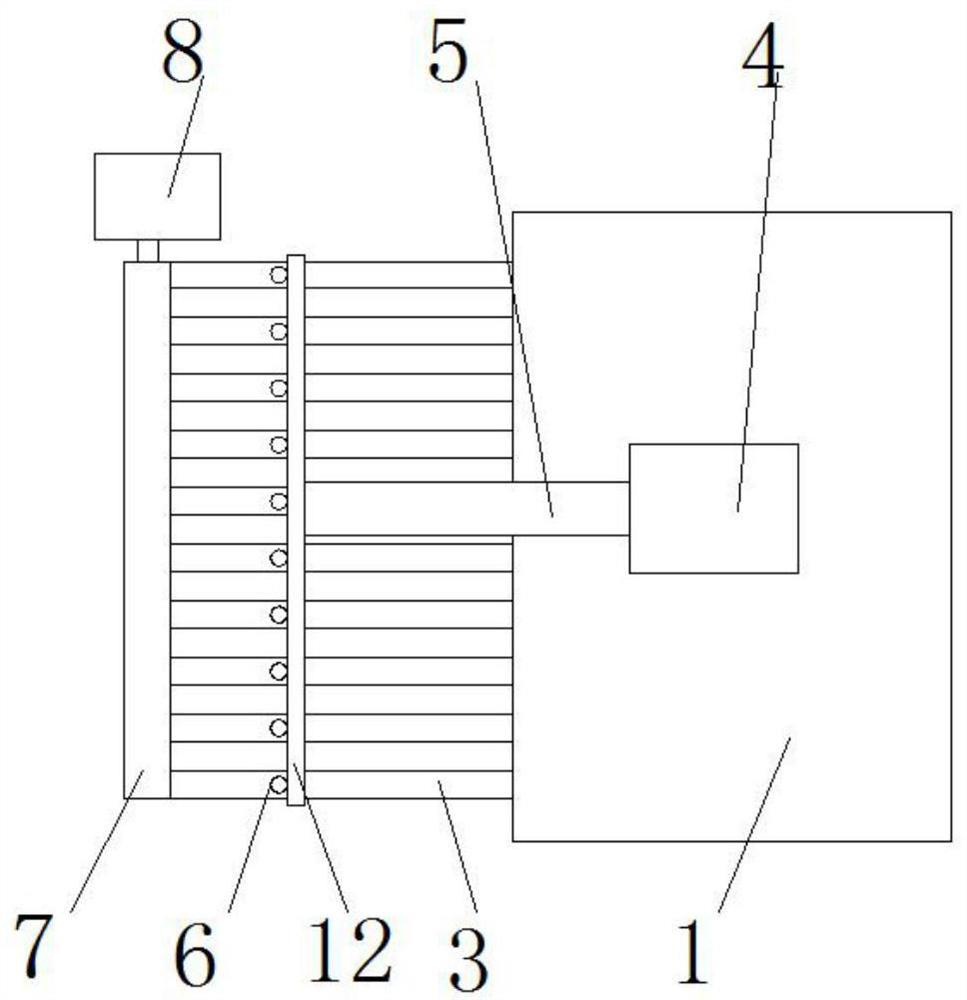

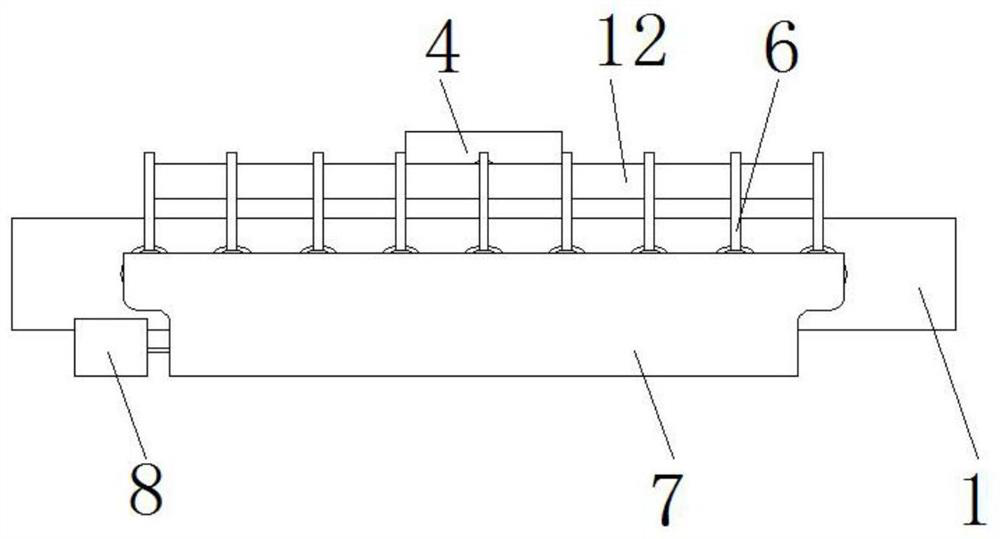

[0018] In this example, refer to Figure 1-3 , a metal heat treatment follow-up annealing device, comprising a box body 1, a plurality of identical slideways 2 are provided inside the box body 1, the slideways 2 are arranged in parallel, the slideway 2 runs through the inner wall of one side of the box body 1, and the slideways 2 A slidable slide bar 3 is arranged inside, a push rod motor 4 is arranged on the top of the box body 1, and a horizontal push arm 5 is arranged at the output end of the push rod motor 4, and the end of the push arm 5 far away from the push rod motor 4 is docked on the slide On the straight rod 6 provided on the top of the bar 3, the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com