Method for reducing corner cracks of medium-carbon boron-containing steel continuous casting sheet billet

A corner crack and slab technology is applied in the field of reducing corner cracks of medium carbon and boron-containing steel continuous casting slabs, which can solve the problems of difficult control of corner crack defects, and achieve the reduction of stress weak points, reduction of embrittlement, and nitrogen fixation. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

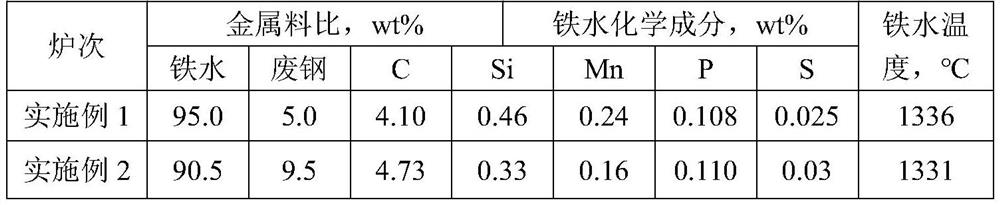

[0024]In the embodiment of the present invention, medium-carbon boron-containing molten steel is smelted in a 250-ton top-bottom double-blown converter, wherein the grade of the steel in Embodiment 1 is AR4160C2, and the grade of the steel in Embodiment 2 is DT4360B1.

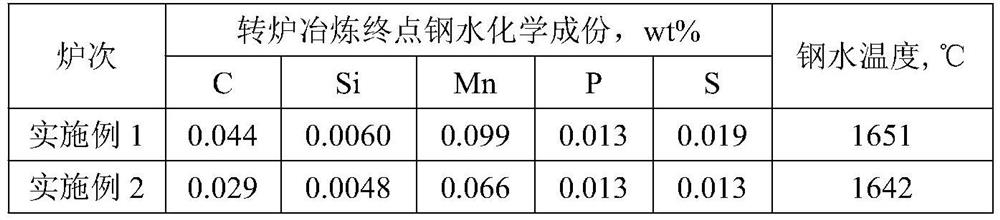

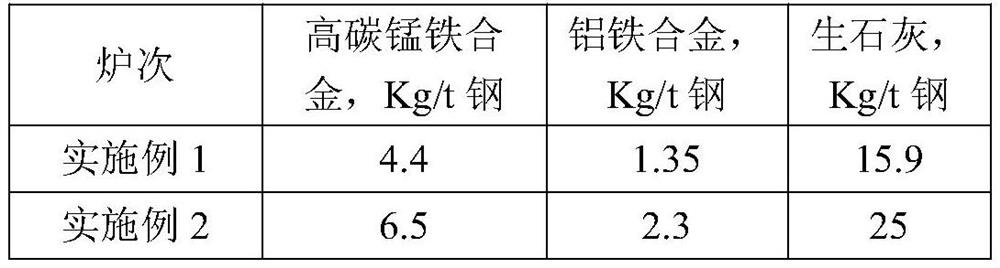

[0025] The bottom blowing gas in the converter smelting process of the embodiment of the present invention is argon, and the production method includes: converter smelting, LF furnace molten steel treatment; straight arc continuous casting machine casting slab. The control parameters of molten steel production in the embodiment of the present invention are shown in Table 1 to Table 7, and the main control parameters are shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com