Geological drill rod

A geological drill and rod body technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of poor torsional performance, corrosion, impracticality, etc., to improve impact resistance, improve torsional performance, improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

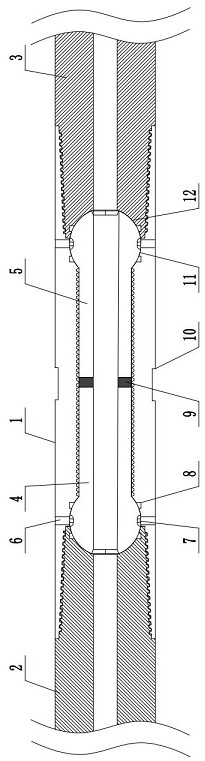

[0023] First embodiment (see figure 1 ):

[0024] Geological drilling rods, including a connecting pipe 1, a left spherical connecting rod 4 and a right spherical connecting rod 5; the left and right ends of the connecting pipe 1 are respectively provided with a left rod body 2 and a right rod body 3; the two ends of the connecting pipe 1 A connecting pipe concave groove 11 is provided; the connecting ends of the left rod body 2 and the right rod body 3 and the connecting pipe 1 are provided with a connecting rod concave groove 12; the outer ends of the left ball connecting rod 4 and the right ball connecting rod 5 It is an arc-shaped structure; the arc-shaped structure is embedded in the arc-shaped groove formed by connecting the connecting pipe concave groove 11 and the connecting rod concave surface groove 12 and fits together; the left ball joint connecting rod 4 and the right ball joint connecting rod The inner end of 5 is embedded in the connecting pipe 1; the arc struc...

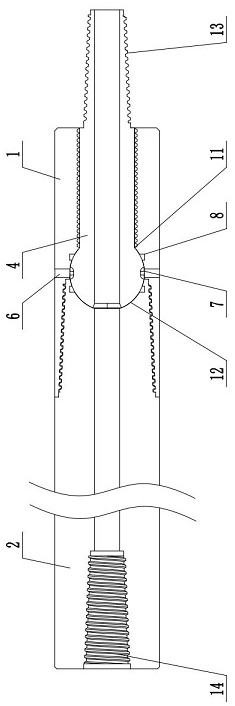

Embodiment 2

[0035] The difference between Embodiment 2 and Embodiment 1 is that a single ball-joint connecting rod is adopted, specifically, one end of the left ball-joint connecting rod 4 is a spherical arc-shaped structure, and the other end is provided with a connecting external thread 13 . At the same time, the left end of the left rod body 2 is provided with a connecting internal thread 14 matching the connecting external thread 13 .

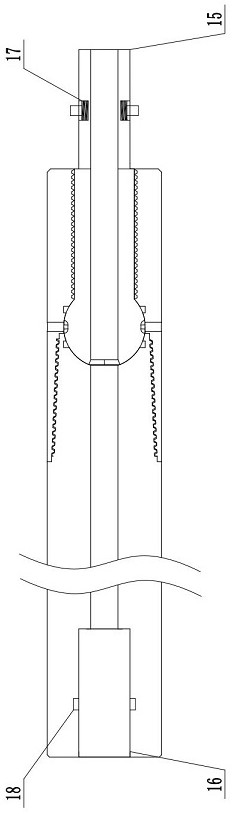

Embodiment 3

[0037] The difference between embodiment 3 and embodiment 2 is that the connecting external thread 13 is replaced by a polygonal prism pin 15 ; meanwhile, the left end of the left rod body 2 is provided with a groove 16 matching the polygonal prism pin 15 . At the same time, the polygonal prism plug 15 is provided with a card bean 17; the groove 16 is provided with a card slot 18 matching the card bean 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com