Connecting assembly, pipeline system and air conditioning system

A technology for connecting components and pipeline systems, which is applied in the direction of sealing surface connection, pipe/pipe joint/fitting, pipeline layout, etc., which can solve the problem of reduced pressure bearing strength of connection materials, which cannot meet the requirements of fast and reliable docking and fastening and sealing effects of product debugging. Dependence and other issues, to achieve the effect of fast locking or loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

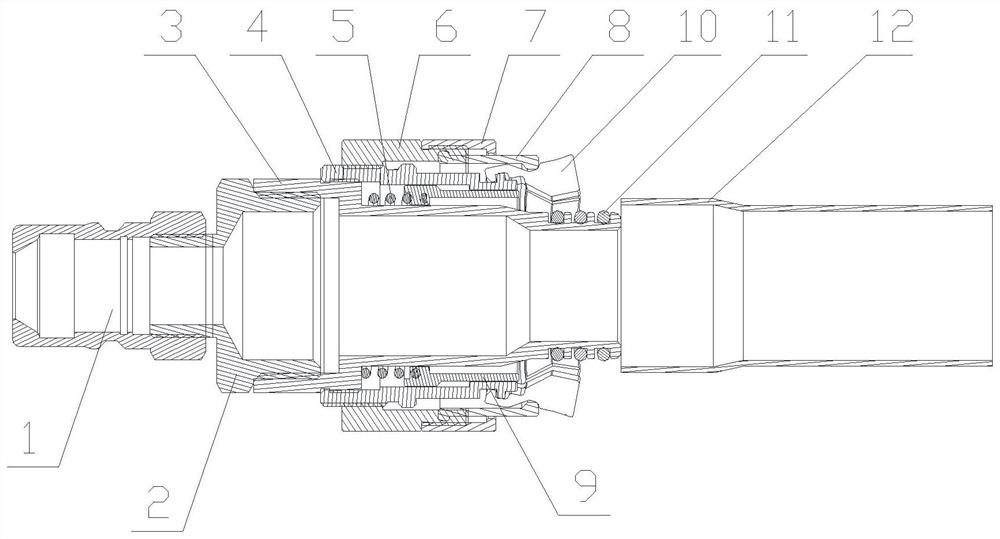

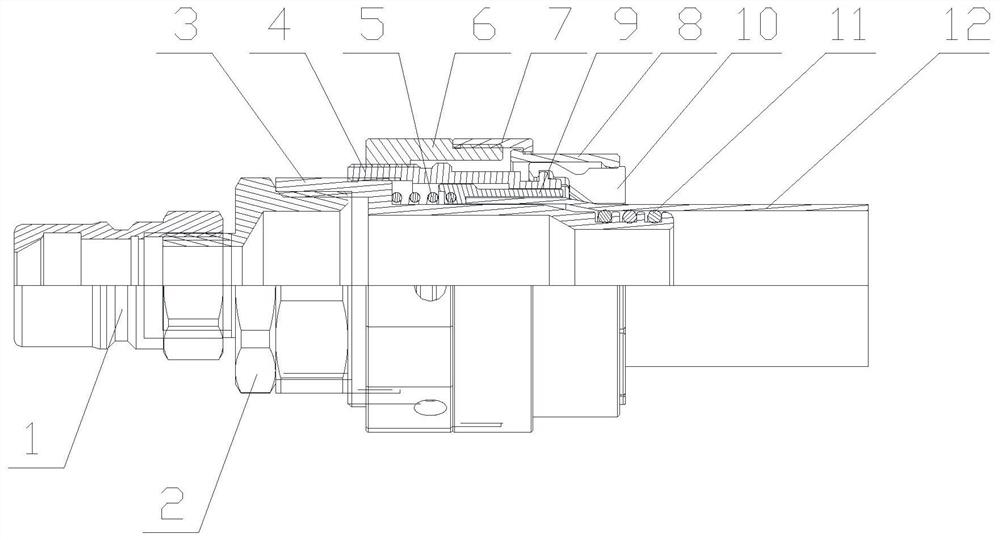

[0025] see in conjunction Figure 1 to Figure 2 As shown, according to the embodiment of the present application, a connection assembly is used to connect the first pipe 12 and the second pipe 1, and the connection assembly includes:

[0026] The lining sleeve 3 includes a first end, and the first pipe member 12 is sheathed on the first end;

[0027] 10 claws are movable on the inner sleeve 3; the 10 claws and the inner sleeve 3 clamp or release the first pipe 12.

[0028] 10 claws are set on one end of the inner bushing pipe 3, and the first pipe member 12 is sheathed on the end of the inner bushing pipe 3, so that the first pipe member 12 can be clamped or loosened by the movement of the claws 10. The opening force can realize the locking or loosening of the pipeline, which can avoid damage to the pipe fittings.

[0029] In some embodiments, the claw 10 includes a claw 10 and an adjustment collar 8, and there are multiple claws 10, which are evenly distributed on the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com