Semiconductor substrate surface chemical processing method apparatus

A technology for chemical treatment and substrate surface, which is applied in the field of wet chemical treatment of semiconductor substrates and chemical treatment of semiconductor substrates. It can solve problems such as failure to meet requirements, poor uniformity, increase the steps of coating and cleaning films, etc., to increase distance, The effect of increasing the distance and eliminating the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

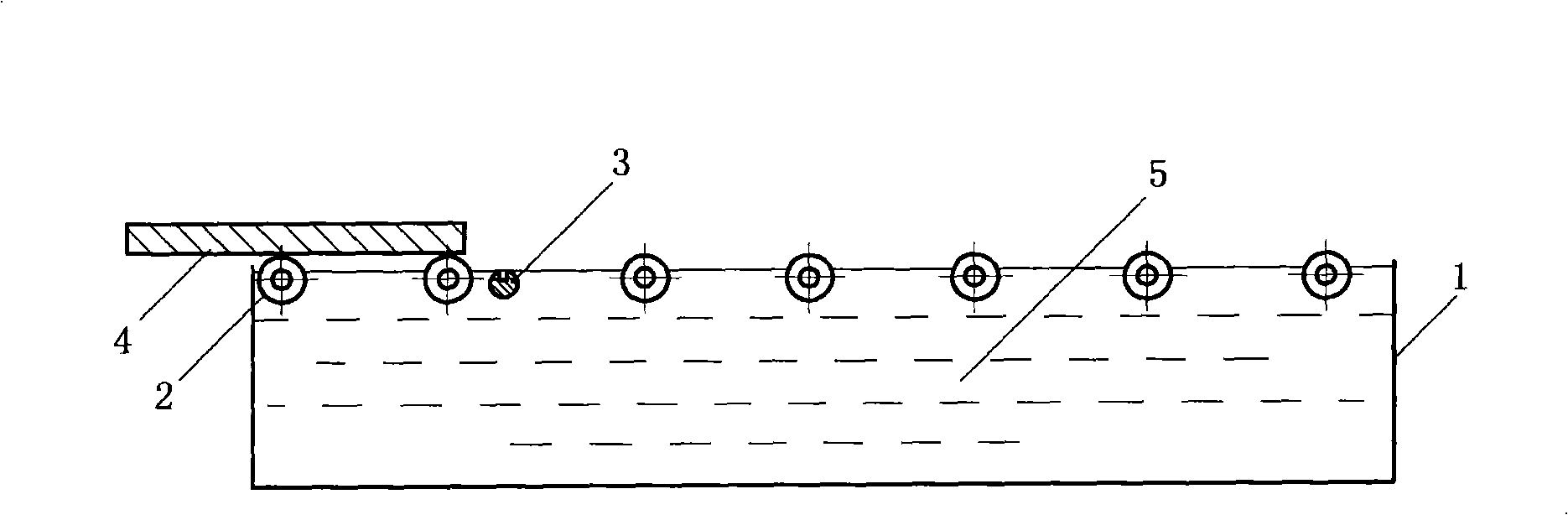

[0064] The chemical solution is a mixed solution of nitric acid and hydrofluoric acid. The injection device uses a nozzle and is fixed. The distance between the lower surface of the semiconductor substrate and the liquid surface of the chemical solution was 2 mm. When one edge of the semiconductor substrate moves over the nozzle, the nozzle sprays the chemical solution once. Then the lower surface of the semiconductor substrate is gradually wetted by the chemical solution under the action of surface tension as the semiconductor substrate continues to move. Throughout the process, the lower surface of the semiconductor substrate is in contact with the liquid level of the chemical solution in the chemical tank. After the treatment, the upper surface of the semiconductor substrate is not wetted by the chemical solution.

specific Embodiment 2

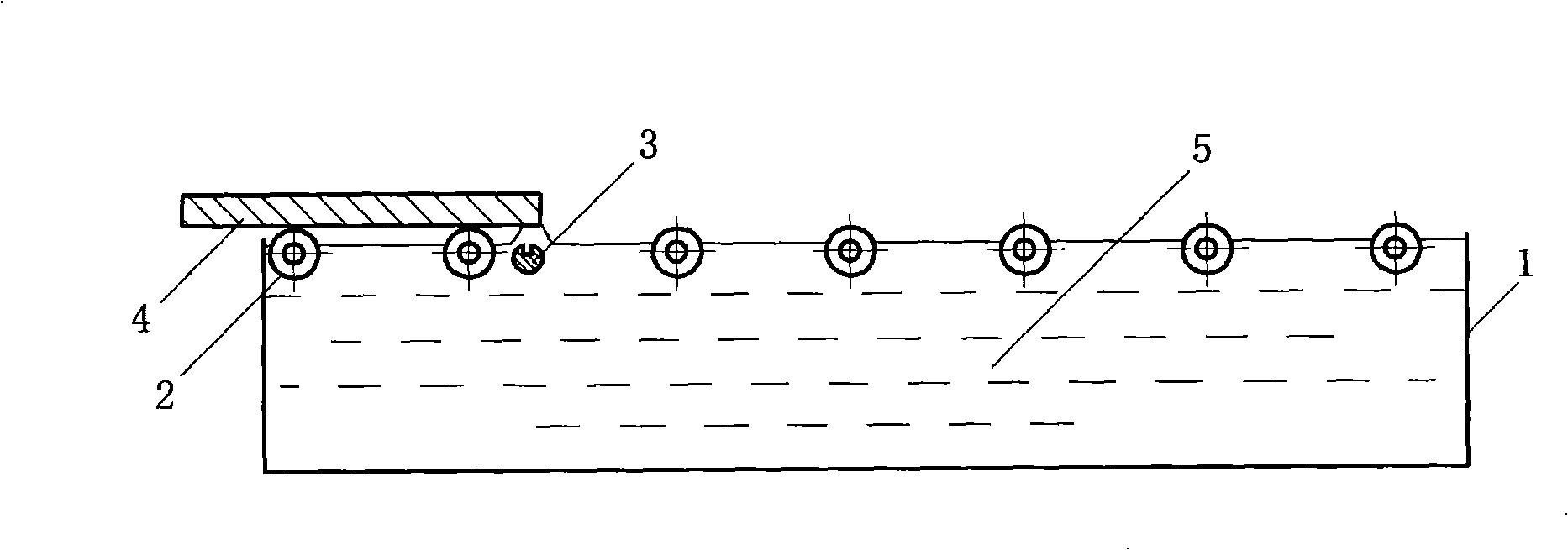

[0065]The injection device adopts multiple nozzles and is fixed. The distance between the lower surface of the semiconductor substrate and the liquid surface of the chemical solution was 10 mm. When one edge of the semiconductor substrate moves above the nozzle, the nozzle starts to spray the hydrofluoric acid solution until the other edge of the semiconductor substrate moves above the nozzle and stops. The semiconductor substrate continues to move, and when one edge of the semiconductor substrate moves above the next nozzle, the nozzle starts to spray the hydrofluoric acid solution until the other edge of the semiconductor substrate moves above the next nozzle and stops. During the whole process, the lower surface of the semiconductor substrate is not in contact with the liquid level of the chemical solution in the chemical tank. After the treatment, the upper surface of the semiconductor substrate is not wetted by the chemical solution.

specific Embodiment 3

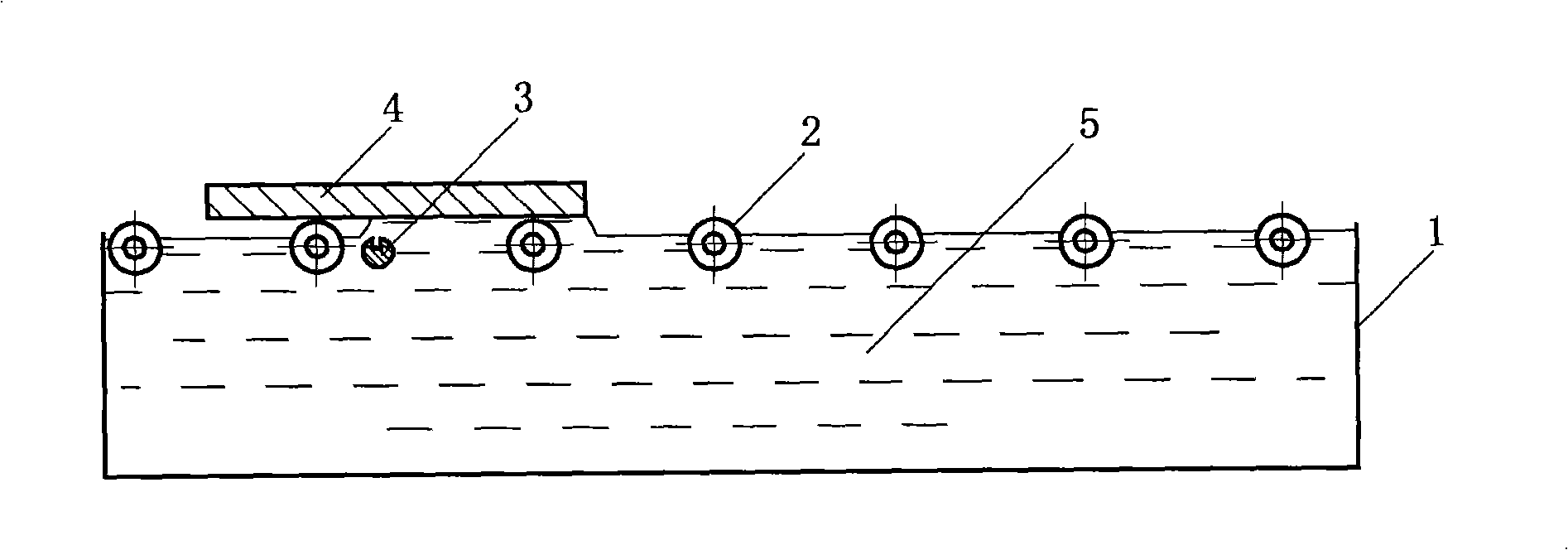

[0066] The chemical solution is an electroless nickel plating solution. The injection device uses a nozzle and is fixed. The distance between the lower surface of the semiconductor substrate and the liquid surface of the chemical solution was 0.1 mm. When an edge of the semiconductor substrate moves above the nozzle, the nozzle starts to spray the electroless nickel plating solution. Continue until the other edge of the semiconductor substrate moves above the nozzle and stop. Throughout the process, the lower surface of the semiconductor substrate is in contact with the liquid level of the chemical solution in the chemical tank. After the treatment, the upper surface of the semiconductor substrate is not wetted by the chemical solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com