Induction cooker with efficient heating plate

A technology of induction cooker and heating plate, which is applied in the direction of household heating, heating fuel, heating method, etc., which can solve the problems of easy failure, inconvenient replacement and maintenance, and easy damage of heating plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

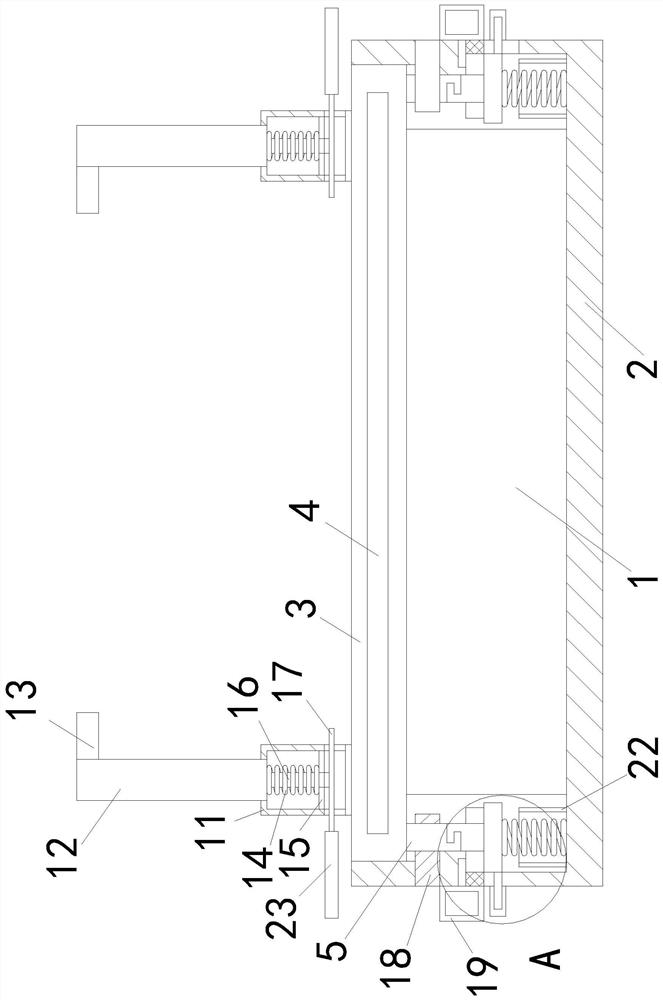

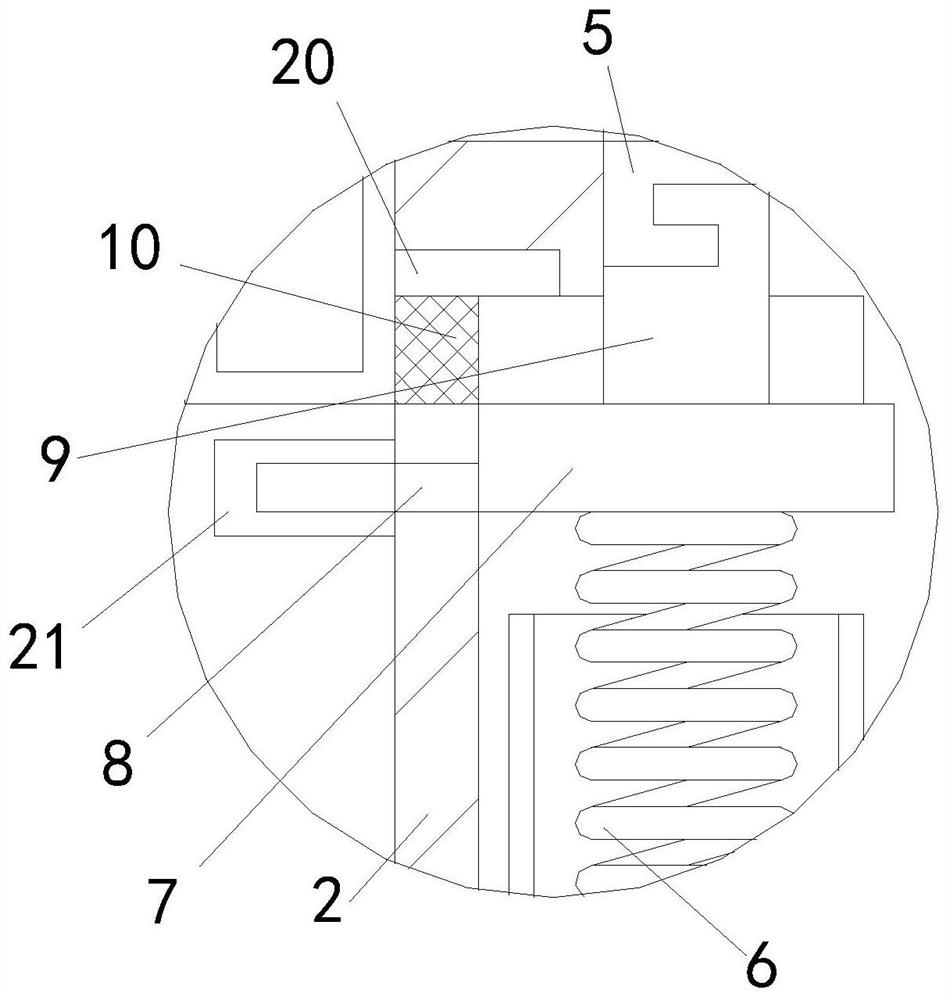

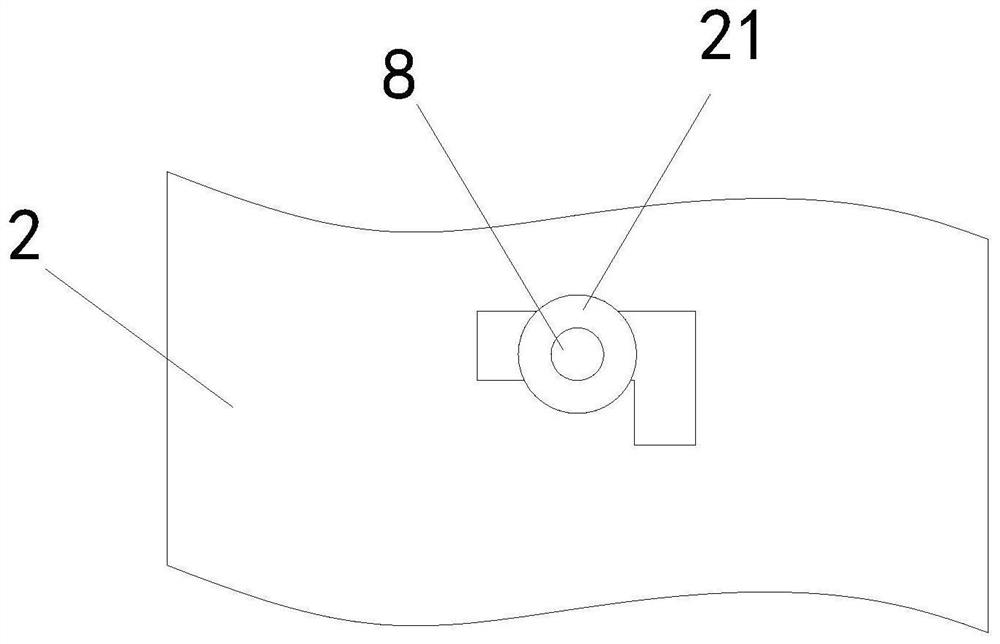

[0027] See Figure 1-5 A electromagnetic cooker with a high-efficiency heating plate includes an electromagnetic furnace body 1 and a support box 2. The upper portion of the electromagnetic furnace body 1 is attached, and a silicon plate 4 is provided inside the heat prevention plate 3, and the top end of the heating plate 3 is provided with clamping. The device, the clamping device includes a fixed tube 11, an upper portion of the fixed tube 11 is provided with an increased plate 12, and the upper portion of the increased plate 12 is fixedly coupled to the finite plate 13, and the bottom end of the increase plate 12 is inserted into the fixed tube 11. The inside, the bottom end of the increase plate 12 is fixedly connected to the second spring 14, the bottom end of the second spring 14 is fixedly connected to the interior plate 15, the inner wall of the outer side wall of the center plate 15, and the bottom of the plate 12 The end fixation is connected to the transfer shaft 16, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com