Supporting seat

A technology of support base and support column, which is applied to optics, instruments, camera bodies, etc., can solve the problems of increasing the difficulty of adjusting the lens, loosening the bolts, and not easy to loosen, so as to avoid the loss of screws and nuts, reduce The use of parts and the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

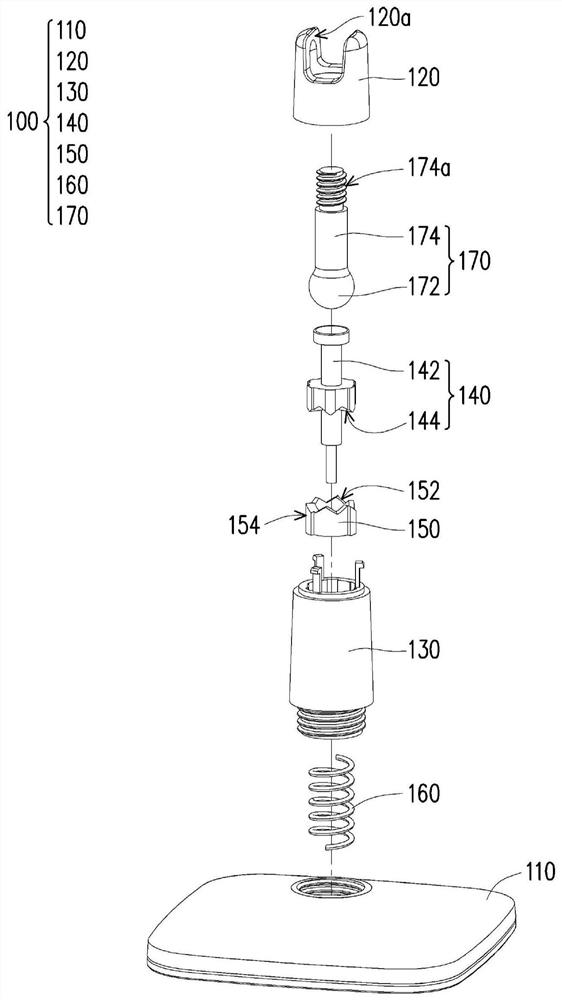

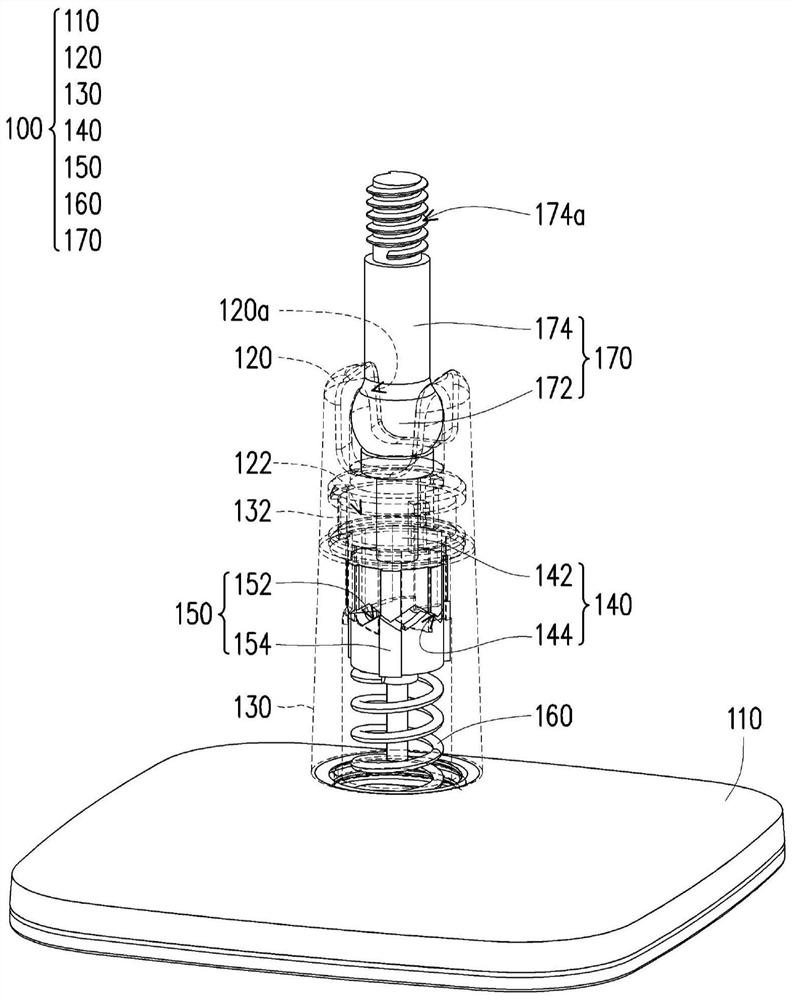

[0056] figure 1 It is an exploded schematic view of the support seat of the embodiment of the present invention, and figure 2 for figure 1 Schematic diagram of the assembly of the support base. Please also refer to figure 1 and figure 2 , the support base 100 of this embodiment is used to support an object, wherein the object may be a surveillance camera or a network camera, but is not limited thereto.

[0057] The supporting base 100 includes a base 110 , a limiting base 120 , a fixing base 130 , a supporting post 140 , a slide rail 150 , an elastic element 160 and a ball shaft 170 . The base 110 can be made of metal or plastic, wherein the base 110 is used to be fixed to a reference surface (not shown), and the reference surface can be a desktop or a wall, which is selected according to actual needs.

[0058] The material of the limiting seat 120 and the fixing seat 130 can be selected from plastic or metal according to requirements, wherein the fixing seat 130 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com