Sound emission signal denoising method based on denoising autoencoder

An acoustic emission signal and autoencoder technology, applied in the field of signal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] 1. Calculation examples

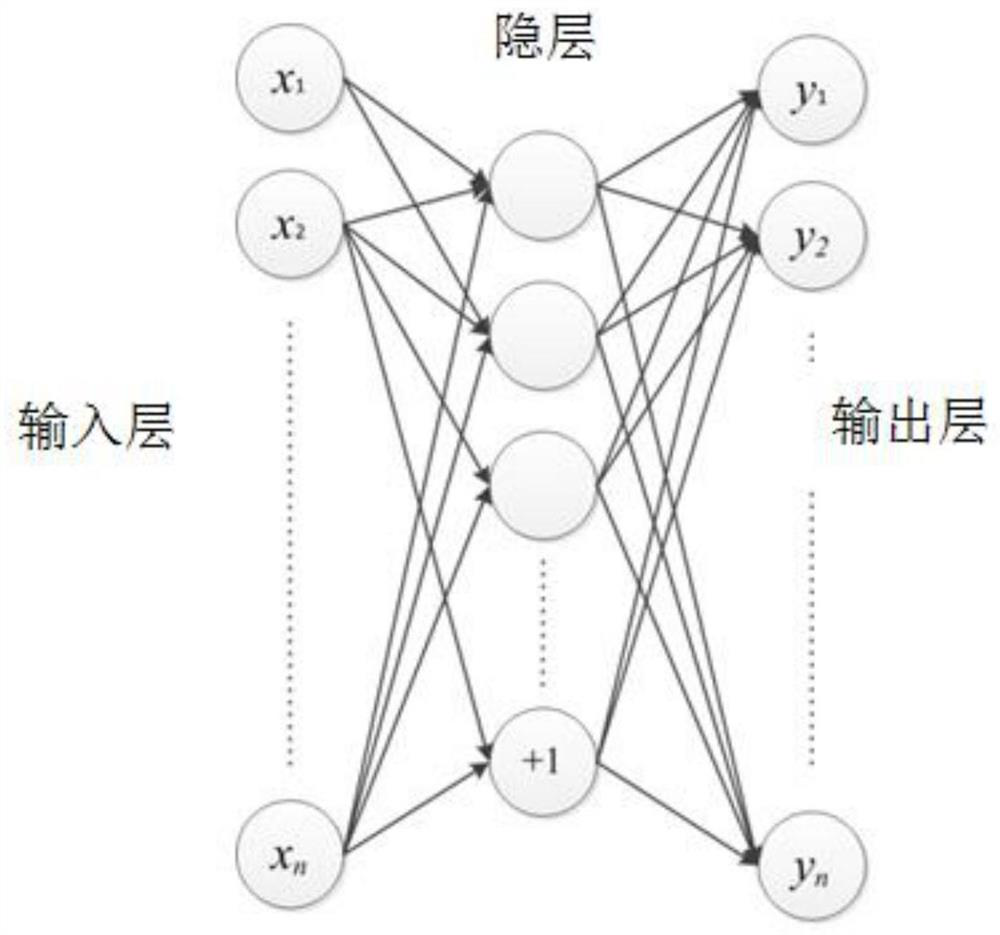

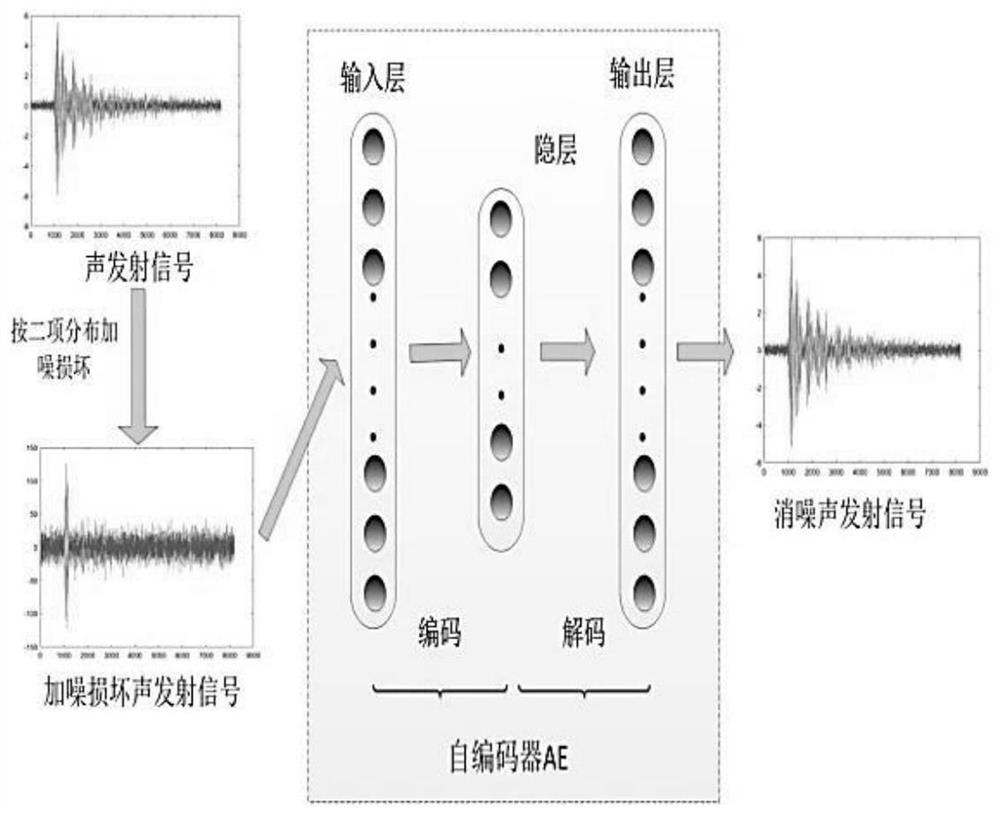

[0076] (1) Determination of the number of neurons in the hidden layer of DAE

[0077] DAE is a neural network with a single hidden layer structure, and the number of neurons in the hidden layer needs to be set according to the actual denoising application scenarios of DAE. Here, the signal-to-noise ratio is used to measure the denoising performance, as shown in formula (10):

[0078]

[0079] Among them, P signal , P noise are the power of signal and noise, respectively; and P signal to attach Figure 5 The normalized corrosion AE signal power shown, P noise is the acoustic emission signal power after denoising and P signal Difference.

[0080] The DAE encoding activation function selects the Logistic sigmoid function, the decoding activation function selects the Positive saturating linear transfer function, and the loss function adopts the mean square error function MSE (Mean SquaredError), as shown in formula (11):

[0081]

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com