Method for selecting wet bulb temperature in yellowing period of flue-cured tobacco baking process

A technology of wet bulb temperature and baking process, which is applied in the fields of tobacco, tobacco preparation, non-electric variable control, etc., can solve the problems of tobacco leaf weight, aspect ratio thickness, wet bulb temperature, etc. The effect of improving economic traits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

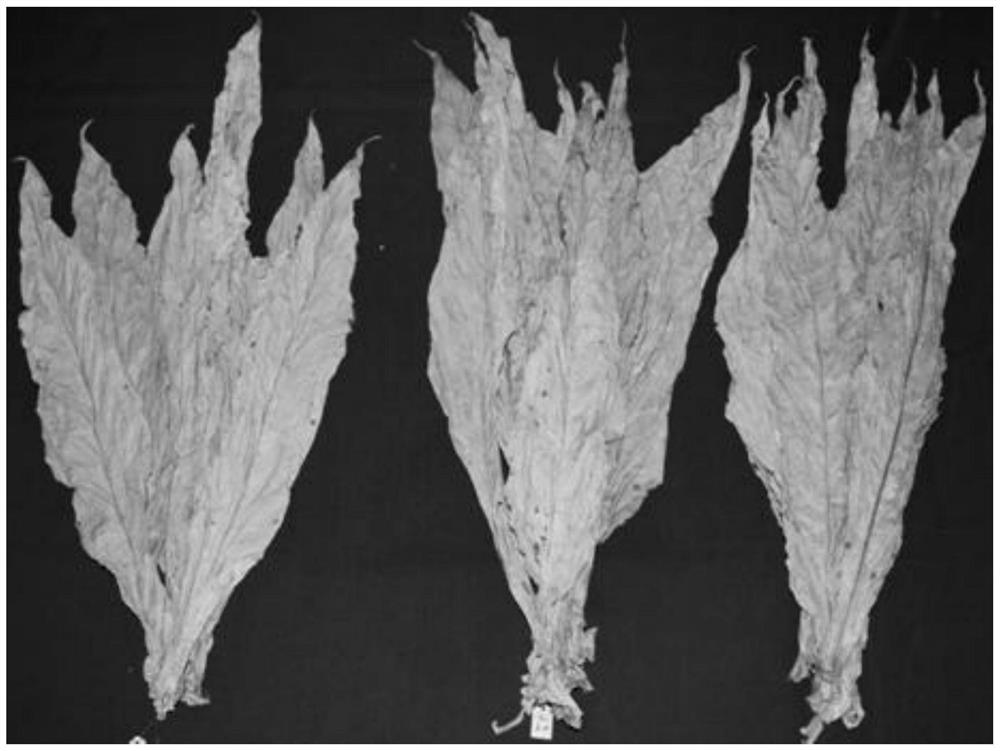

Image

Examples

Embodiment 1

[0026] Yunyan 87 in a certain place in Enshi, Hubei was selected as the tobacco leaf plants to be tested, and three tobacco fields with normal plant growth were selected, numbered T1, T2, and T3 respectively. 5 points were randomly selected in the three fields, and 2 tobacco leaf plants with the same growth were harvested at each point, a total of 10 tobacco plants were used as the tobacco plants to be tested, and 2 upper leaves of the tobacco plants to be tested were taken as the tobacco leaves to be tested. The following method is used to obtain the wet bulb temperature during the yellowing period of the Yunyan 87 flue-cured tobacco curing process:

[0027] S1, establish the following discriminant model of the index parameter of fresh tobacco leaf and the wet-bulb temperature of yellowing period;

[0028] Y 1 =-705.262+1381.013×water content value-2.957×chlorophyll content value-5.015×thickness value-3.812×leaf base branch width value+108.402×aspect ratio value; Y 1 The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com