Construction waste graded crushing equipment

A technology for crushing equipment and construction waste, applied in grain processing, etc., can solve the problems of insufficient strength, fluffy finished product structure, etc., and achieve the effect of fine processing and easy reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

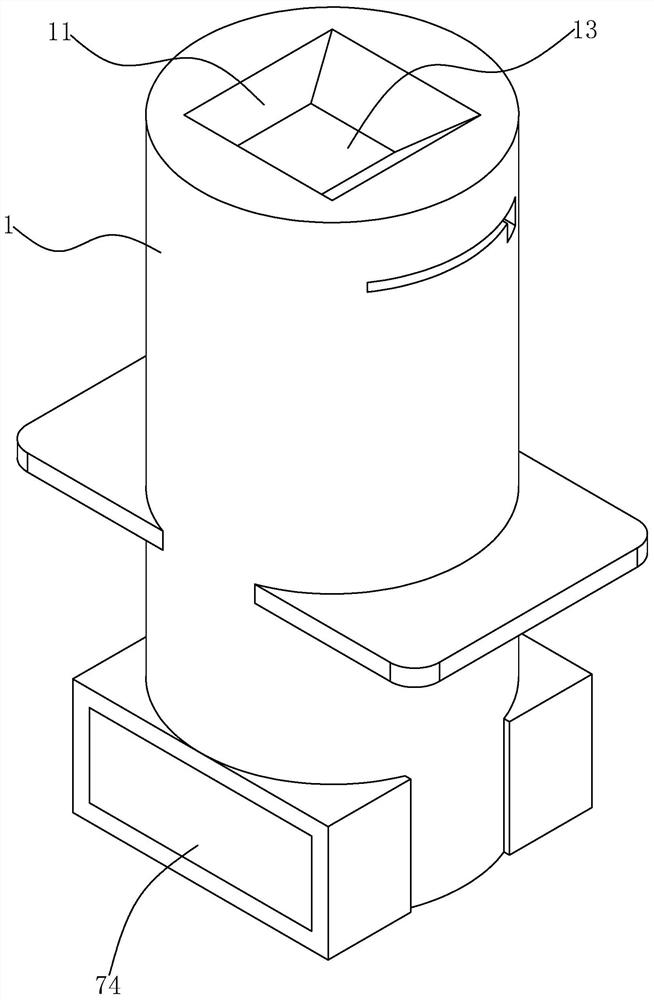

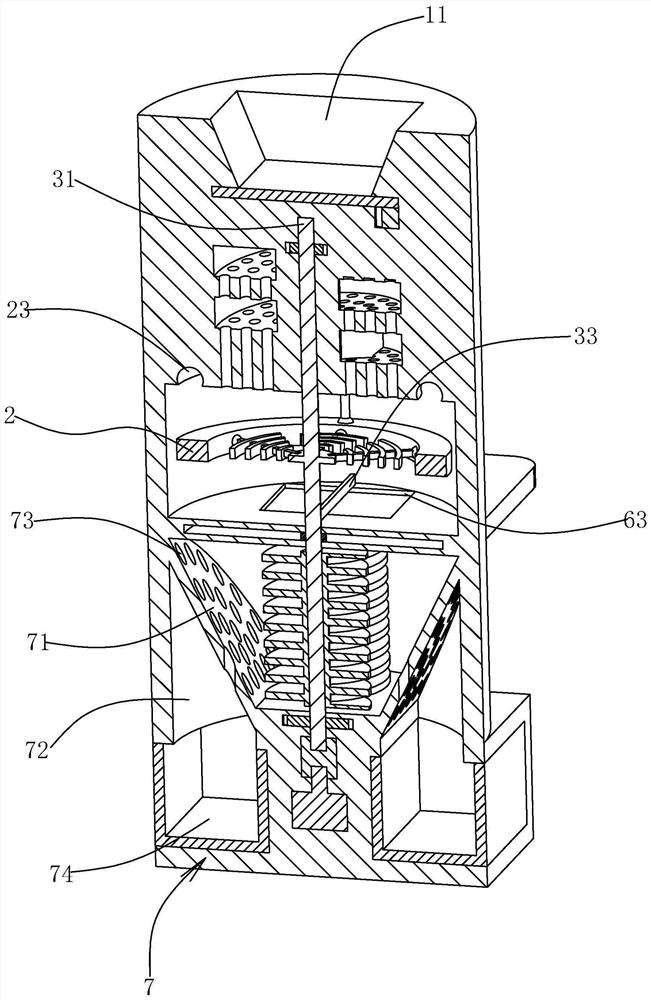

[0035] A construction waste classification crushing equipment, such as figure 1 As shown, the box body 1 is provided with the feed port 11, the position of the feed port 11 is provided with a partition 13, and the lower end of the box body 1 is also provided with a receiving box 74.

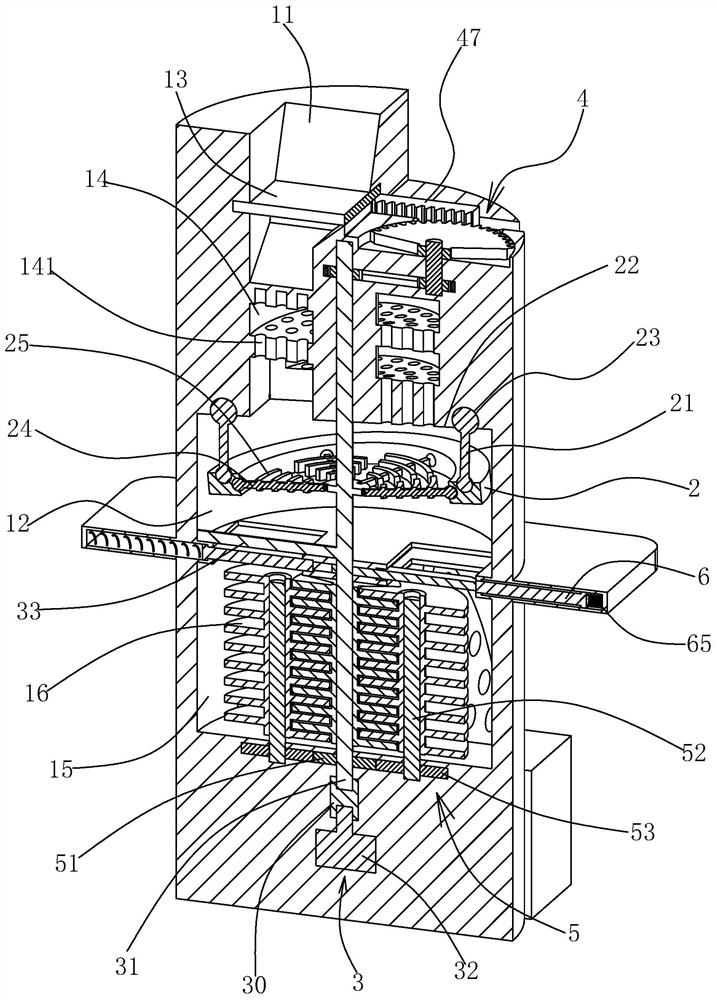

[0036] Such as figure 2 As shown, the lower end of the feed port 11 is provided with a crushing chamber 12, and the crushing chamber 12 is provided with a driving device 3 for driving the crushing plate 2 to initially crush gravel; The plate 13 moves back and forth, and then controls the driving force of the intermittent conduction between the feed port 11 and the arc-shaped feed channel 14. The arc-shaped feed channel 14 is provided with several vertically connected crushing chambers 12 and the arc-shaped feed channel. 14 screen holes 141; the lower end of the driving device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com