Secondary dust-removal equipment used for separating fine particulate matter dust in tail gas

A technology for fine particles and secondary dust removal, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as difficult handling, poor fire safety, and restrictions on use occasions, and achieve space saving, resistance reduction, and energy saving The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

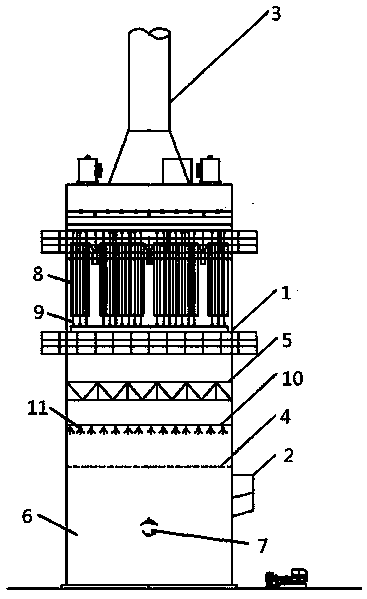

[0026] It can be seen from the accompanying drawings that a secondary dedusting equipment for separating fine particle dust in exhaust gas includes a tower body 1, and a spray dedusting device and a wet electrostatic dedusting device are arranged in the tower body 1 sequentially from bottom to top. The left end of the tower body 1 is provided with a flue gas inlet 2, and the upper end of the tower body 1 is provided with a flue gas outlet 3. The spray dust removal device includes an air distribution plate 4, a first spray device and a demisting device arranged in sequence from bottom to top. A waste water recovery tank 6 is arranged under the air distribution plate 4, the flue gas inlet 2 is arranged between the air flow distribution plate 4 and the waste water recovery tank 6, and an overflow tank 7 is arranged on the waste water recovery tank 6 .

Embodiment 2

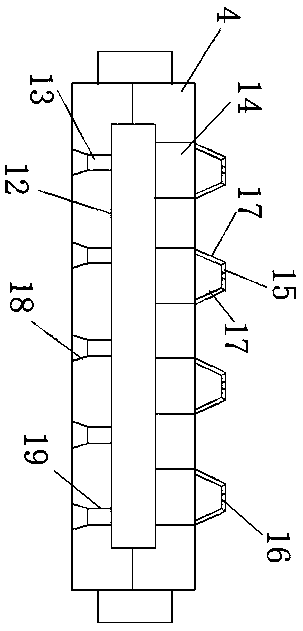

[0028] As an improvement of the present invention, the wet electrostatic precipitator includes an anode tube 8, a cathode line 9 and a second spray device, the upper and lower ends of the anode tube 8 are connected to the tower body 1, and each cathode line 9 all pass through an anode tube 8 correspondingly, and the cathode line 9 is connected to the tower body 1 by hanging in the air, and a second spraying device is arranged above the anode tube 8 and the cathode line 9 .

[0029] The rest of the structural features and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0031] As an improvement of the present invention, the first spraying device includes a spraying pipeline 10, a water tank, a pump and a spraying head 11, the water tank is connected to the spraying pipeline 10 through a pump, and the spraying pipeline 10 is provided with There are shower heads 11, and the number of said shower heads 11 is at least two. All the other structures and advantages are identical to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com