Cleaning device for aluminum profile extrusion die

A technology for extrusion dies and cleaning devices, which is applied in the field of extrusion dies and can solve problems such as die erosion, stains on the die surface, and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

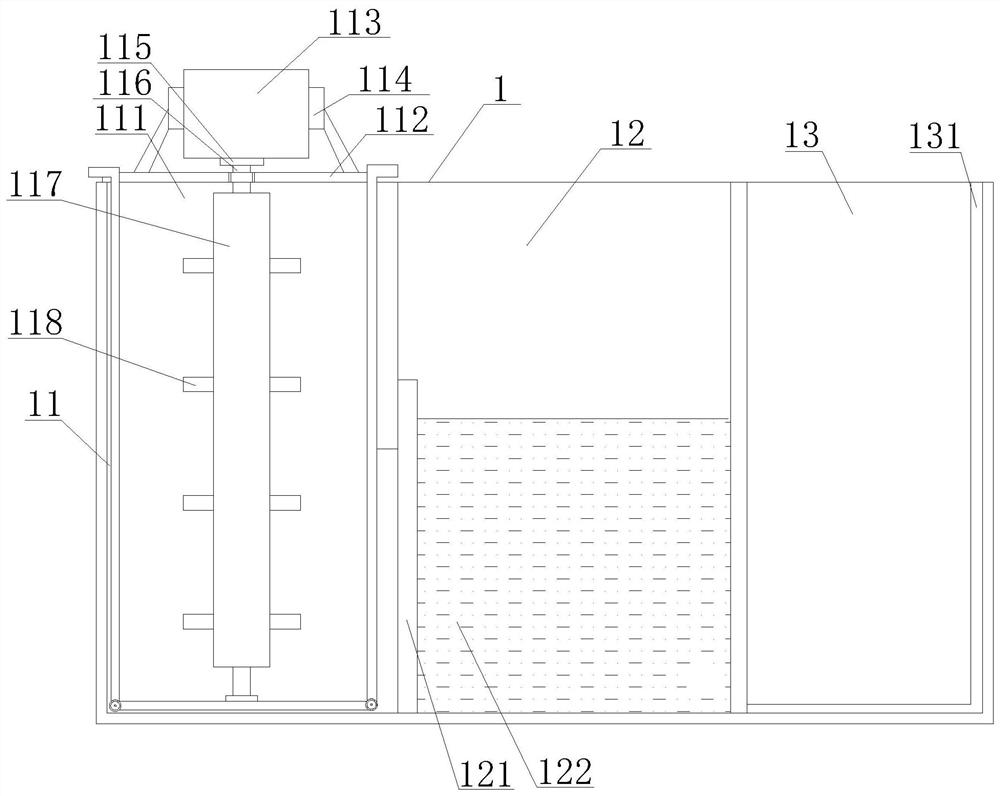

[0041] Such as Figure 1-6 As shown, the present invention provides a cleaning device for aluminum profile extrusion dies, including a cleaning device body 1, a movable chamber 11 and a heating chamber 13 are arranged on both sides of the cleaning device body 1, and the middle part of the cleaning device body 1 is provided with The collection bin 12, one side of the movable bin 11 is fixedly connected with one side of the collection bin 12, and the other side of the collection bin 12 is fixedly connected with one side of the heating bin 13.

[0042] In this embodiment, through the setting of the movable bin 11, the cleaning of the mold has a certain space, and through the setting of the collecting bin 12, the sewage 122 after cleaning the mold can be stored, and the heating bin 13 can be used again, so that the mold can be cleaned. The moisture inside the mold evaporates to keep the mold dry.

Embodiment 2

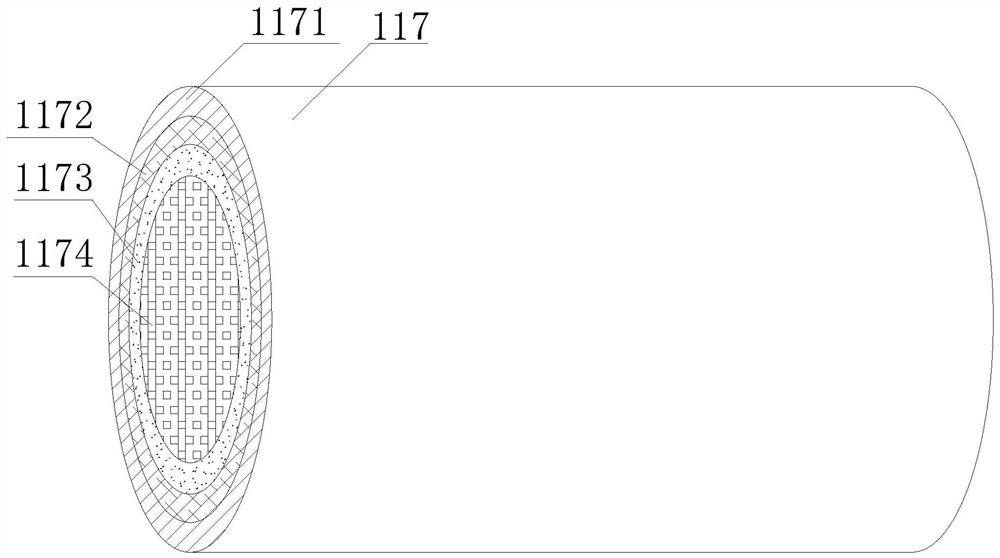

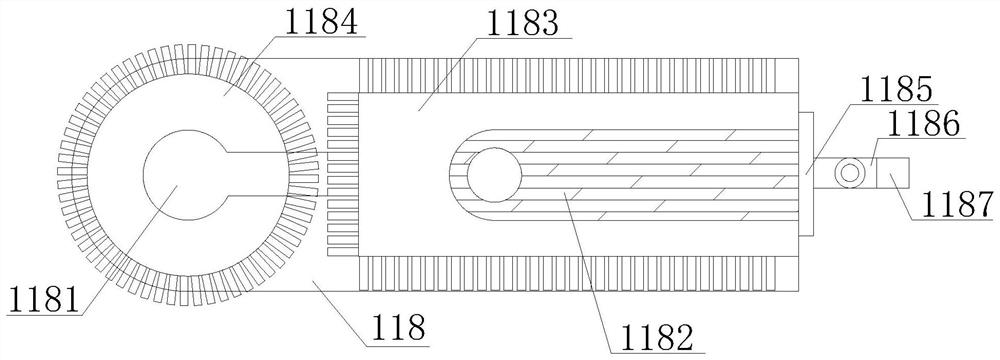

[0044] Such as Figure 1-6As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the movable bin 11 includes a rotating rod 117, the outer surface of the rotating rod 117 is movably connected with a cleaning rod 118, and the inside of the movable bin 11 is movably connected There is a cleaning bin 111, the upper end of the cleaning bin 111 is movably connected with a fixed cover 112, the upper end of the fixed cover 112 is fixedly connected with a fixed support frame 114, and the inner side of the fixed support frame 114 is fixedly connected with a power box 113, the output of the power box 113 The end is movably connected with connecting block 115, and the lower end of connecting block 115 is fixedly connected with transmission rod 116, and the outer surface of transmission rod 116 is fixedly connected with the inwall of rotating rod 117, and the both sides of rotating rod 117 are movably connected with the inboard of cleaning ...

Embodiment 3

[0047] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the heating chamber 13 includes a heating plate 131, the heating plate 131 is arranged on the inner wall of the heating chamber 13, and the bottom end of the inner wall of the heating chamber 13 is fixedly connected There is a partition plate 132 , fixed blocks 133 are fixedly connected to both sides of the inner wall of the heating chamber 13 , and the heating plate 131 , the partition plate 132 and the fixed block 133 are all arranged inside the heating chamber 13 .

[0048] In this embodiment, through the combined setting of the heating chamber 13, the heating plate 131, the partition plate 132 and the fixed block 133, the cleaned molds are placed on both sides of the partition plate 132, and when there are too many molds, go up Just add up. After the placement is over, the heating plate 131 actually heats up. When heated to a certain extent, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com