Filter drum and drum chip removal machine

A kind of drum and filter technology, which is used in filtration and separation, moving filter element filters, metal processing machinery parts, etc., can solve the problems of inaccurate positioning and fixing of filter mesh installation, affecting filtration accuracy, and clogging of cutting chips, etc. Simple structure, convenient operation and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

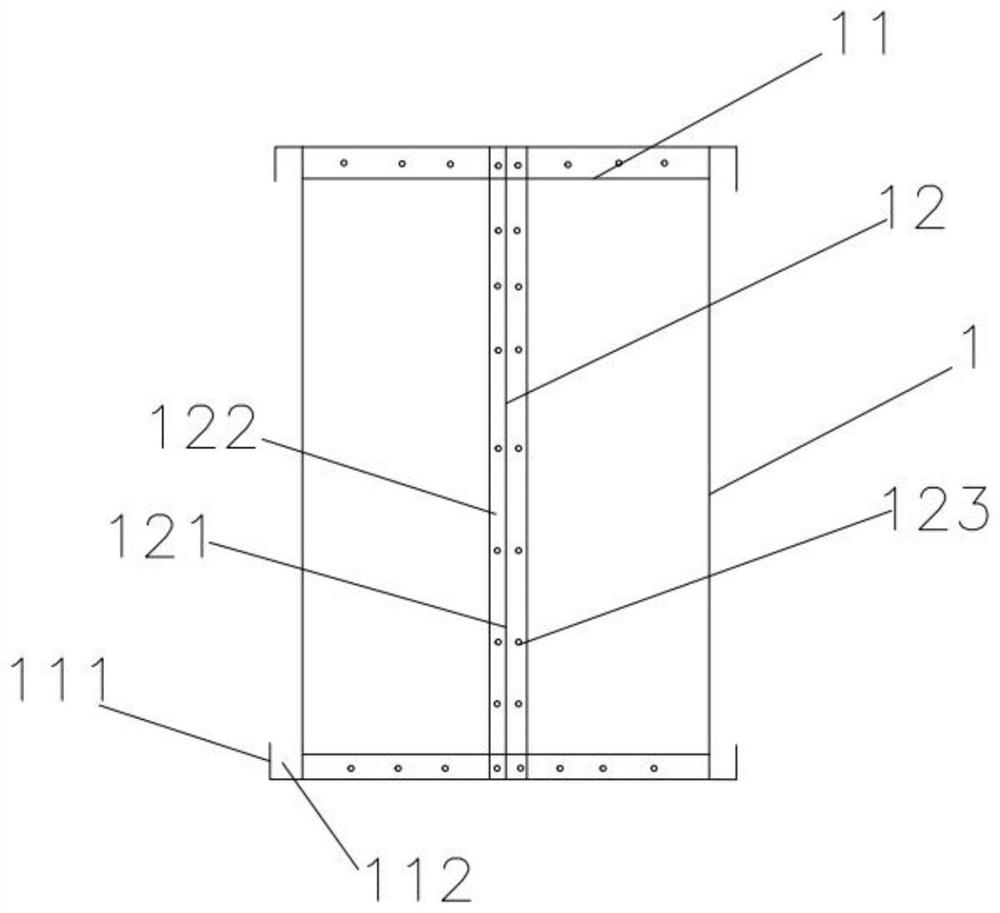

[0016] The filter drum and the drum chip removal machine of the present invention will be described in detail below with reference to the accompanying drawings.

[0017] Such as figure 1 As shown, the filter drum of the present invention includes a drum frame and a filter screen installed on the drum frame, and is characterized in that the drum frame includes an upper end 11, a lower end and a connecting portion 12 connecting the upper end and the lower end, and the upper end 11 and the lower end are hollow rings, a circle of first supporting arc surface 112 is formed downward along the inner surface of the ring, the connecting portion 12 is fixedly connected with the first supporting arc surface 112, and the connecting portion 12 is formed along the length direction. The second supporting arc surface 122, the filter screen is fixed to the second supporting arc surface 122 by fasteners.

[0018] Preferably, three connecting parts 12 are arranged at equal angles along the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com