Bridge curve type tower column outer formwork system

A curved and external formwork technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of not fully meeting the design arc requirements of curved tower columns, poor appearance of curved tower columns, and uneven arc joints and other problems to achieve the effect of avoiding construction safety risks, beautiful appearance, and improving linear accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

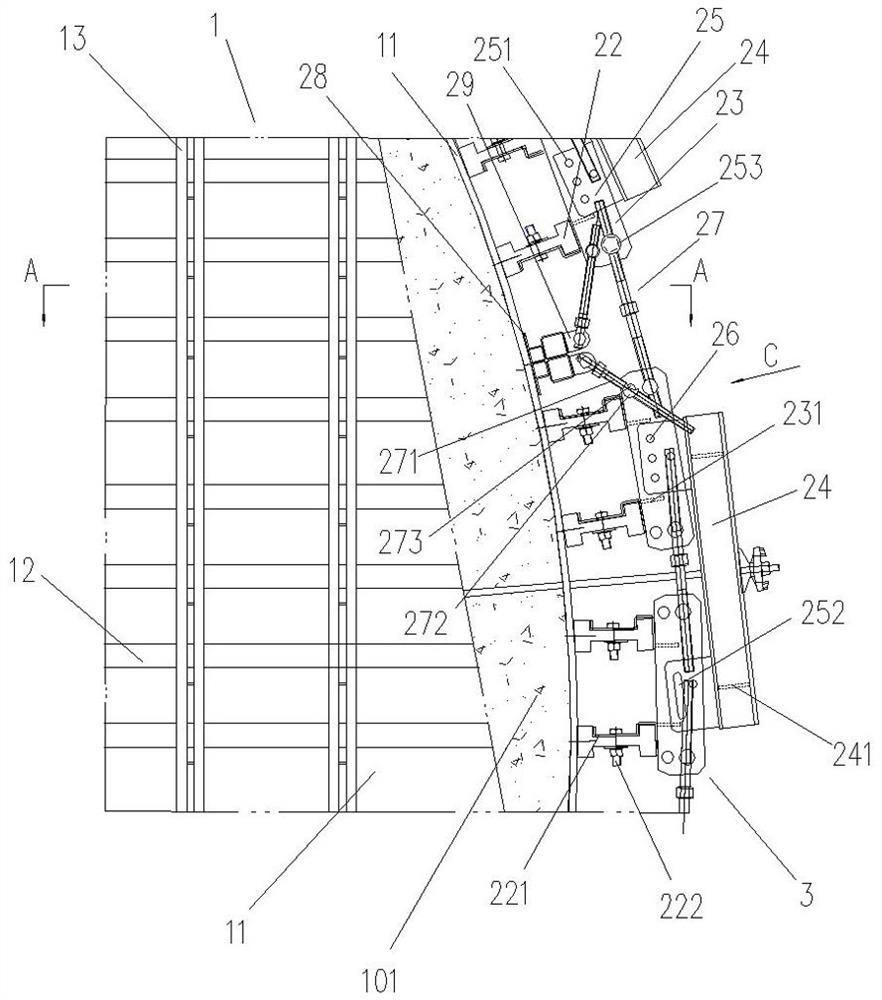

[0019] The present invention will be further described below in conjunction with the accompanying drawings and the embodiment of the present invention being used in the construction of curved tower columns of Hangzhou Jiuqiao Road Bridge.

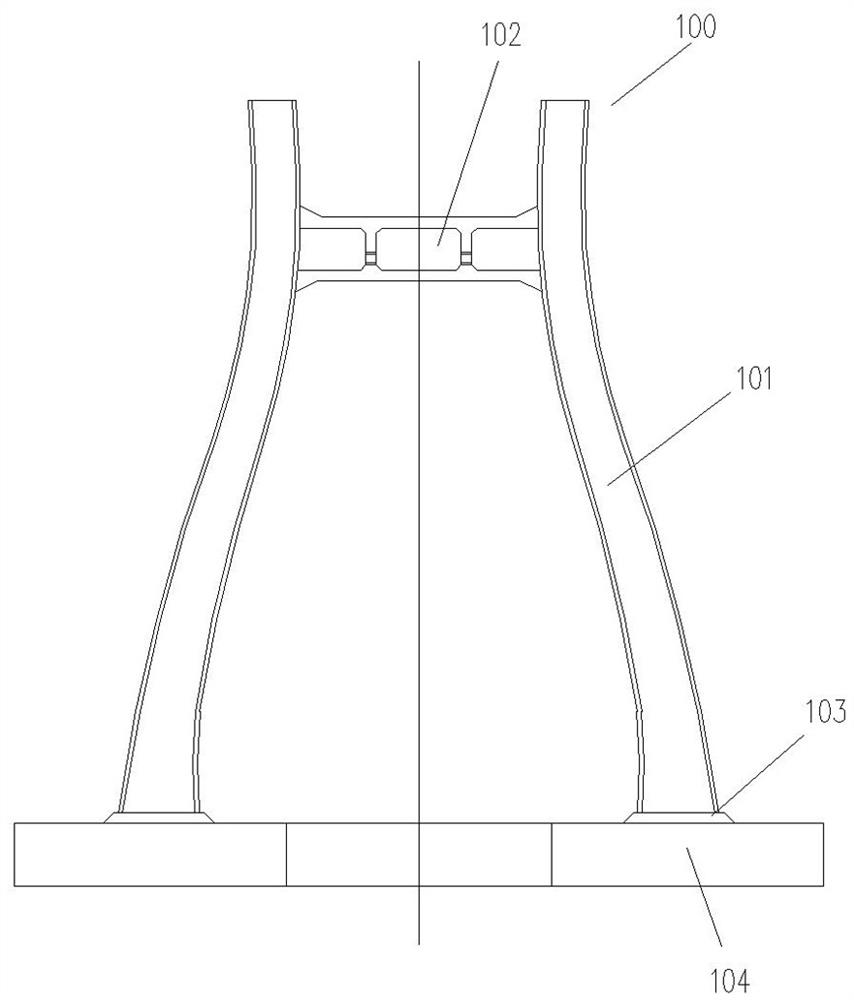

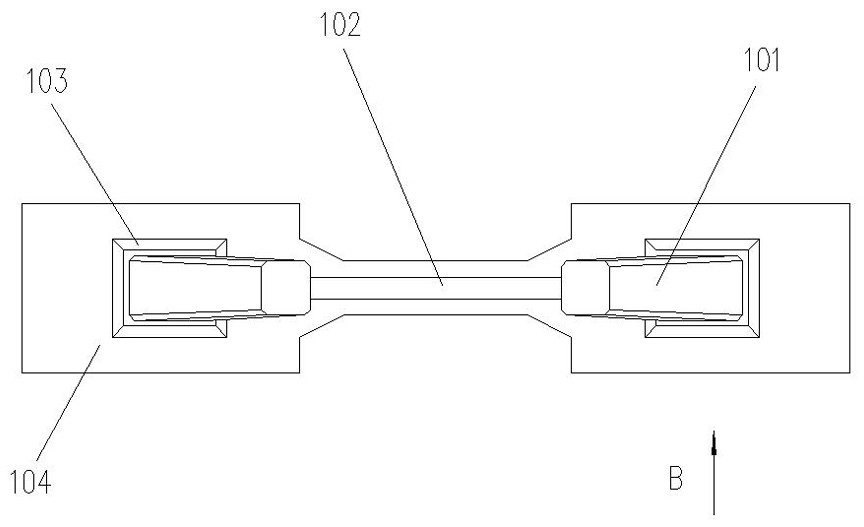

[0020] Such as figure 1 As shown, the Jiuqiao Road Bridge in Hangzhou is a self-anchored suspension bridge with a single-tower and four-span composite girder. The thickness is 1.2m, the section size of the tower root is 7.5×6.0m, the section size of the tower top is 4.5×5.0m, the four corners are chamfered at 0.5×0.5m, and the solid section is used within 3m from the tower root and the tower top. diaphragm. The cross-sectional size of the curved tower column 101 changes with the height transition. The curved tower column 101 is divided into 4 sections of arc transition along the tower height. The construction of the main tower is divided into 19 sections. The standard section height is 4m.

[0021] In the description of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com