Construction method for high-precision wavy pavement for automobile test

A technology of automobile testing and construction methods, which is applied to pavement, roads, roads and other directions paved with prefabricated blocks, and can solve the problems of difficult construction and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A high-precision corrugated road construction method for automobile testing, including prefabricated corrugated road prefabricated parts and installation of corrugated road prefabricated parts and pouring of pavement concrete, the steps of prefabricated corrugated road prefabricated parts are as follows:

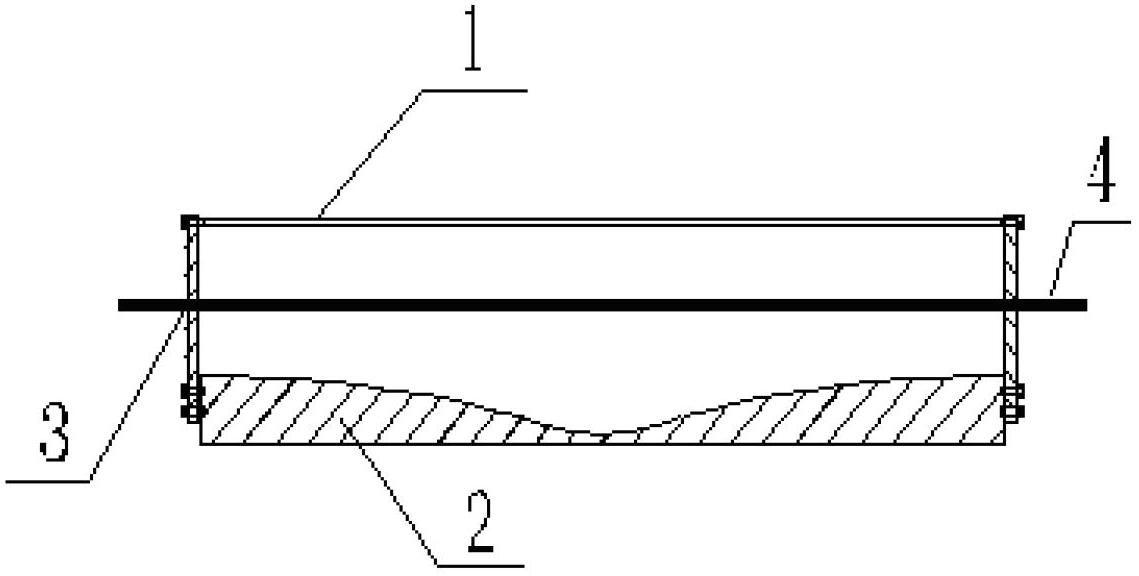

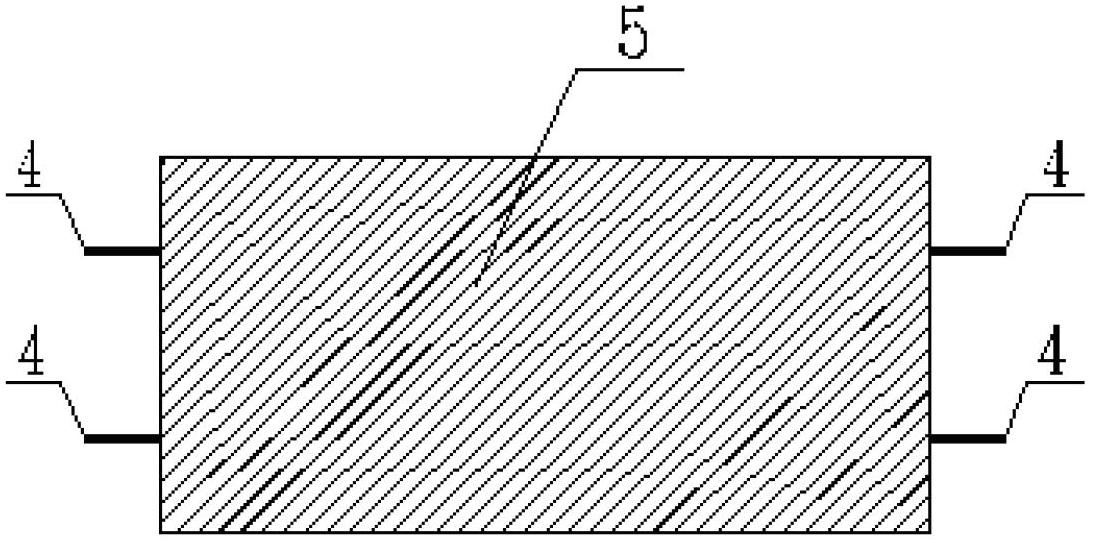

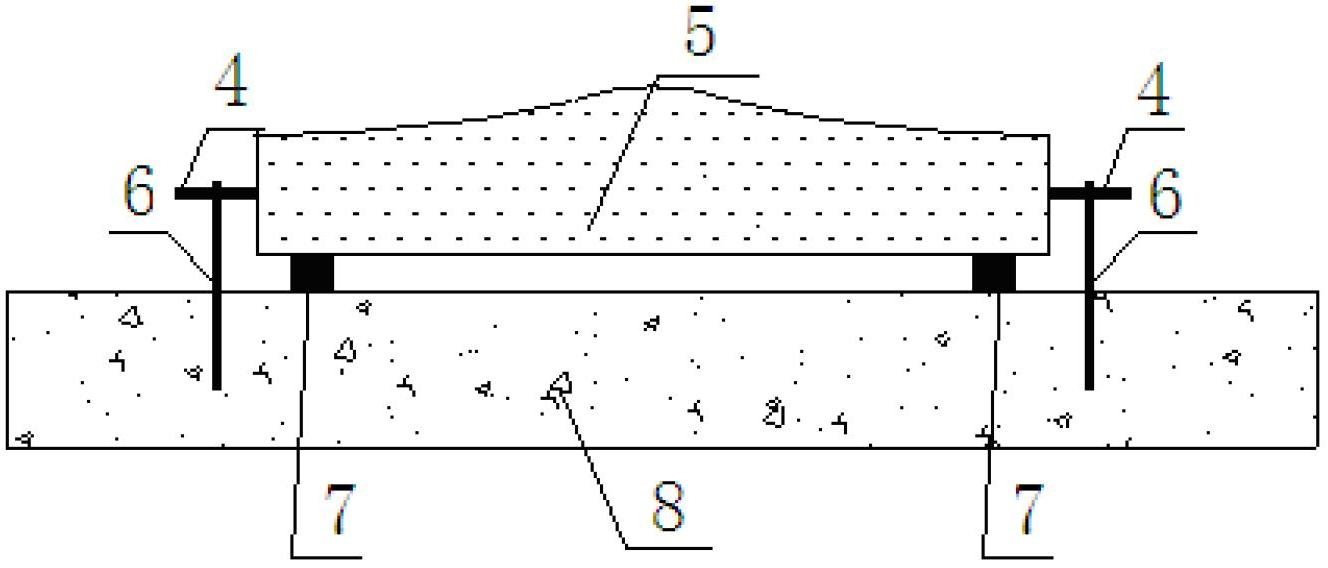

[0028] Such as figure 1 As shown, the prefabricated part mold is processed, and the cast steel tire mold 2 is adopted. According to the waveform and size of the wavy road, the surface of the tire mold 2 is set to be a sinusoidal concave surface, and the side mold 3 is erected on the side of the tire mold 2. By bolts and The gasket connects the tire mold 2 and the side mold 3, and the tie rod 1 is straddled between the two side molds 3 to position the side mold 3 and the tire mold 2 to form a 90° shape. Such as figure 2 As shown in the figure, pouring the wave-shaped road prefabricated blocks, in order to facilitate the movement of the prefabricated parts and the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com