Flapping type kiln sealing device

A technology of transmission wheels and components, which is applied in the direction of clay preparation devices, clay mixing devices, furnaces, etc., can solve the problems of burning kiln burns and consuming a lot of energy, and achieve the effect of tight application, simple operation, and improved working efficiency of kiln sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

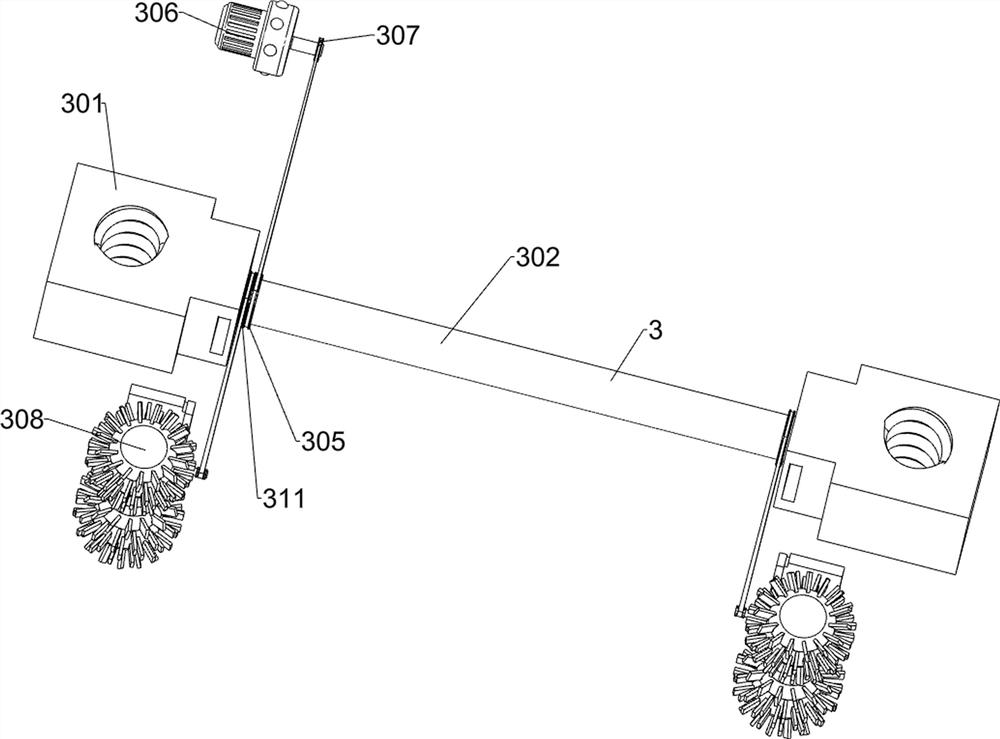

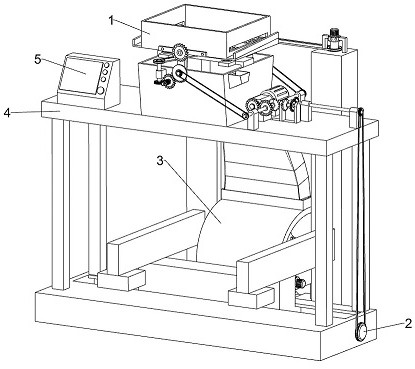

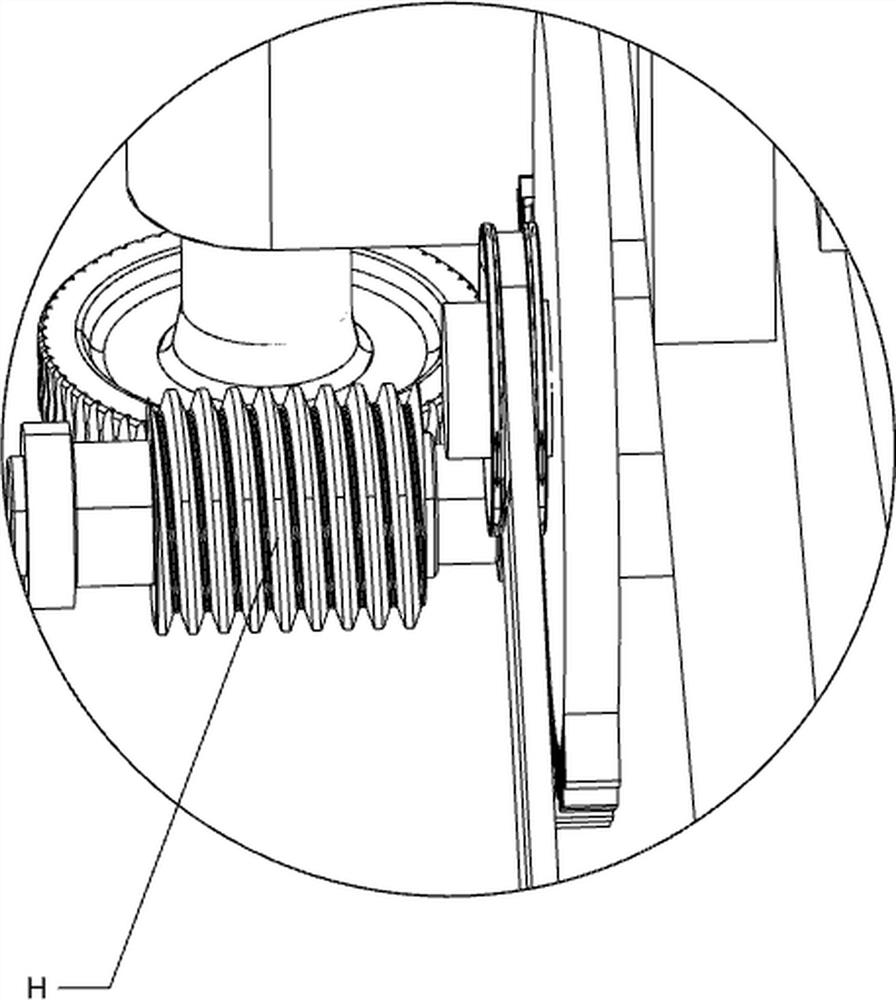

[0035] A beating type kiln sealing device, such as Figure 1-15 As shown, it includes a stirring assembly 1, a displacement assembly 2, a mud filling assembly 3, a support platform 4 and a console 5; the stirring assembly 1 is connected with the displacement assembly 2; the stirring assembly 1 is connected with the mud filling assembly 3; the stirring assembly 1 It is connected with the support platform 4; the displacement component 2 is connected with the mud filling component 3; the displacement component 2 is connected with the support platform 4; the console 5 is connected with the support platform 4.

[0036] Working process: when in use, first place the device and keep the support platform 4 stable, connect the external power supply, control the console 5 to adjust the device, and then the operator pours the yellow mud and accompanying mud into the mixing component 1, and the mixing component 1 mixes the yellow mud. After sieving, mix with accompanying mud material evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com