Back-rolled straw-covered agricultural greenhouse

A technology for agriculture and greenhouses, applied in the field of agriculture, can solve problems such as affecting the lighting of back-facing greenhouses, expanding the shadow area of greenhouses, increasing the distance between greenhouses, etc., achieving good promotion and application value, reducing shadow width, and eliminating occlusion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

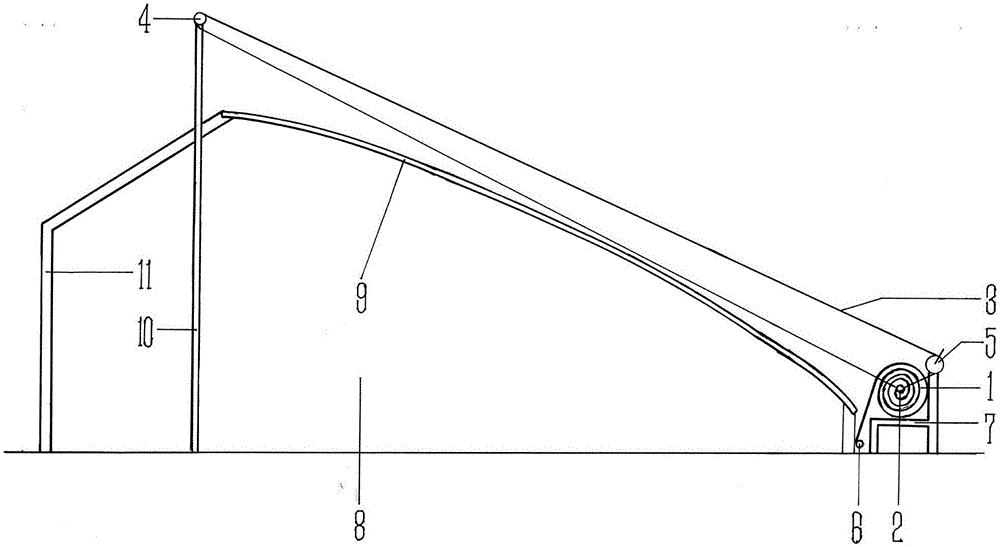

[0016] In conjunction with the accompanying drawings of the description, the inverted thatch quilt agricultural greenhouse of the present invention is further described in detail as follows:

[0017] Such as figure 1 As shown, a chair-shaped thatch quilt frame 7 is arranged in front of the shed 8 composed of a thermal insulation wall 11, a column 10 and a dome 9, and two or several span-linked winches 5 are arranged at the upper end of the chair back of the chair-shaped thatch quilt frame 7 , an elevated pulley 4 is set above the column 10, and several pieces of interlaced thatch are fixed on the fixed rod 6 by a group of one end, and the other end is fixed on the reel 2, and the fixed rod 6 is fixed on the front insulation wall 11 of the greenhouse 8 At the root, the two ends of the reel 2 are provided with shaft moving devices. The noose 3 is fastened to the capstan 5, and the shaft device of the tack reel 2 is tied to the capstan after bypassing the pulley 4. Adjacent thatc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com