A device and method for recovering gas released from pipe networks using ang technology

A technology of releasing gas and recovering pipes, which is applied to the method of container discharge, container filling method, equipment discharged from pressure vessels, etc., can solve environmental problems such as pollution, resource waste, etc., and achieve environmental pollution mitigation, environmental protection, and quantity little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Taking a 1000m-long high-pressure gas pipeline with maintenance (pressure 4.0MPa, temperature 20°C) as an example, the natural gas reserves stored in this pipeline section are 33000Nm calculated according to the pipe diameter of the West-East Gas Pipeline (pipe diameter is about 1000mm) 3 , and it is assumed that the gas source gas meets the design standard.

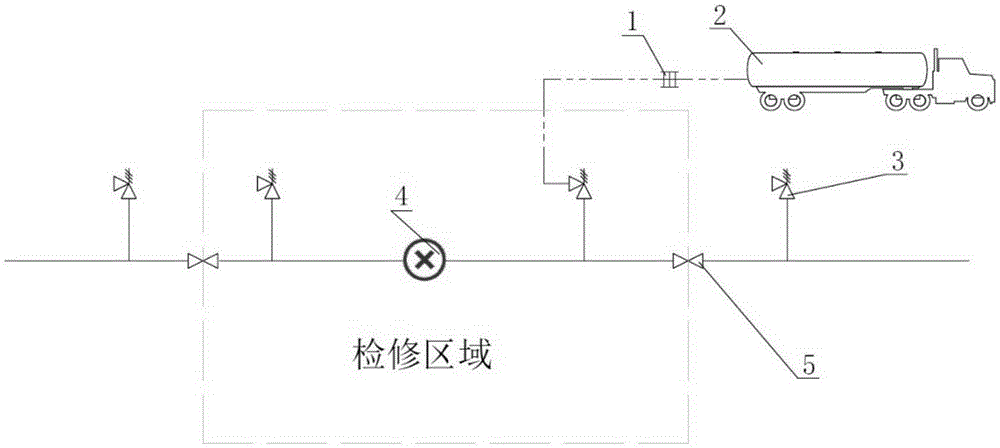

[0054] In application, use the cut-off valve 5 to isolate the pipe section, connect the device to the general interface 1 and the relief valve 3 on the pipe section; open the main control valve 6, and the online chromatographic detector 7 starts working at the same time to analyze the composition of the intake air. After the detection by the chromatographic detector 7 is completed, the device starts to run.

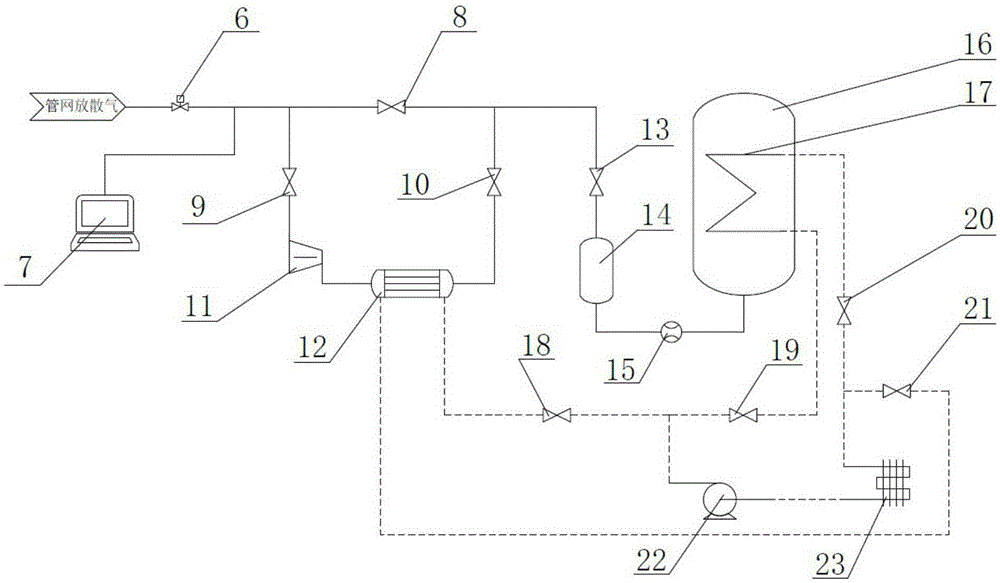

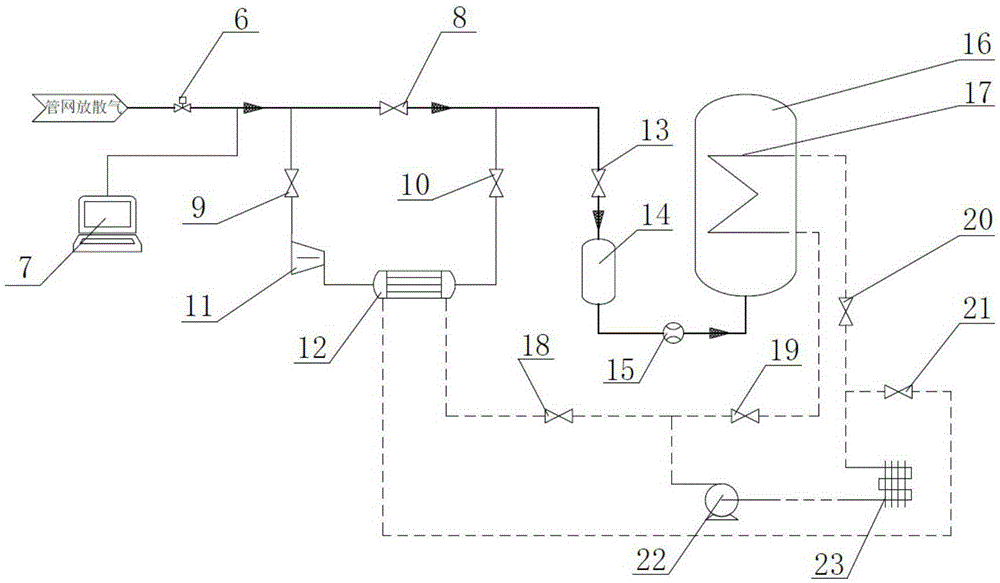

[0055] In the initial stage, since the intake pressure is 2.5MPa higher than the minimum gas storage pressure, the control system closes the second control valve 9 and the third control valve 10, opens the fi...

Embodiment 2

[0060] see figure 1 , figure 2 and Figure 5 , this embodiment is the same as the device of embodiment 1. The difference between this embodiment and Embodiment 1 is that this embodiment is an example of utilizing the vented gas stored in the ANG recovery vehicle.

[0061] The effective gas storage volume of the ANG gas storage tank on the ANG recovery vehicle is 45m 3 , the gas storage pressure is 3MPa as an example, the natural gas reserves stored in this pipeline section are 5400Nm 3 .

[0062] In application, connect the device to the common interface 1 and the air inlet of the downstream user; open the main control valve 6, and the device starts to run.

[0063] During the gas consumption process of desorption and degassing, the control system keeps the second control valve 9 and the third control valve 10 closed, opens the first control valve 8, and the natural gas in the ANG gas storage tank 16 is measured through the flow rate 15 and flushed. The pre-adsorption t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com