Vibrating wire type surface strain gauge and use method thereof

A strain gauge and vibrating wire technology, which is applied in the field of civil engineering testing instruments, can solve problems such as falling off and poor device stability, and achieve the effects of avoiding falling, improving the scope of application, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

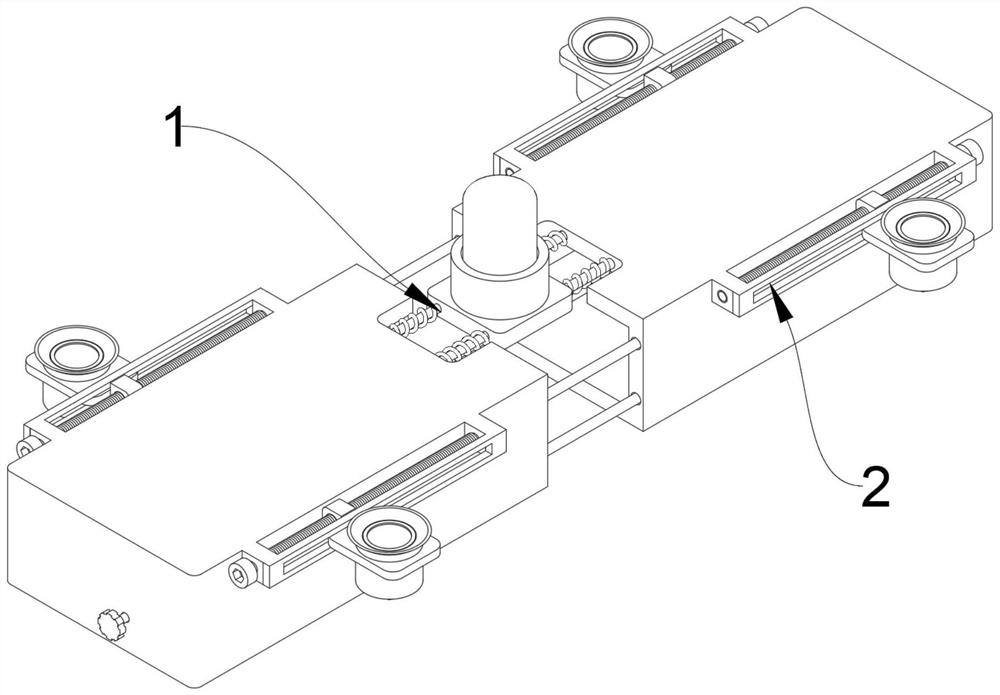

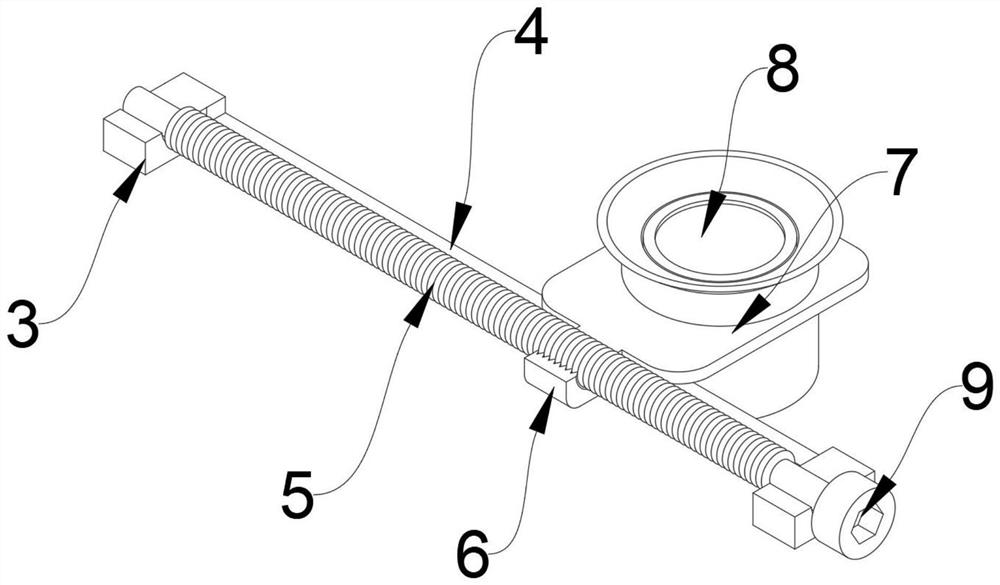

[0041] see Figure 1-6 As shown, the present invention is a vibrating wire surface strain gauge, comprising a strain gauge body 1, and both sides of both ends of the strain gauge body 1 are fixed with a fixing mechanism 2, and the fixing mechanism 2 includes a slide rail 3, and the inside of the slide rail 3 is provided with There is a working chamber 4, and the inside of the working chamber 4 is slidingly connected with a transmission block 6, and one end of the transmission block 6 is fixed with a fixed plate 7, and an adsorption mechanism 8 is installed inside the fixed plate 7, and the middle position of the working chamber 4 is rotatably connected with a threaded rod 5;

[0042] Here, one end of the threaded rod 5 is fixed with a transmission cap 9, and the transmission cap 9 can be one of an outer hexagonal cap or an inner hexagonal cap;

[0043] When in use, the transmission cap head 9 is rotated by a wrench, and the threaded rod 5 will be driven to rotate when the tra...

Embodiment 2

[0056] A method for using a vibrating wire surface strain gauge is disclosed on the basis of Embodiment 1, the steps of which are as follows:

[0057] Step 1: Turn the transmission cap 9 with a wrench during use. When the transmission cap 9 rotates, it will drive the threaded rod 5 to rotate, because the transmission block 6 and the threaded rod 5 are connected by threads, and the transmission block 6 is slidingly connected in the working chamber 4, when the threaded rod 5 rotates, it will drive the transmission block 6 to slide inside the working chamber 4, so that the position of the fixed plate 7 can be adjusted through the transmission block 6, so that the device can be fixed on concrete with different shapes, and the steel bars inside the concrete Testing, thus greatly improving the scope of application of the device;

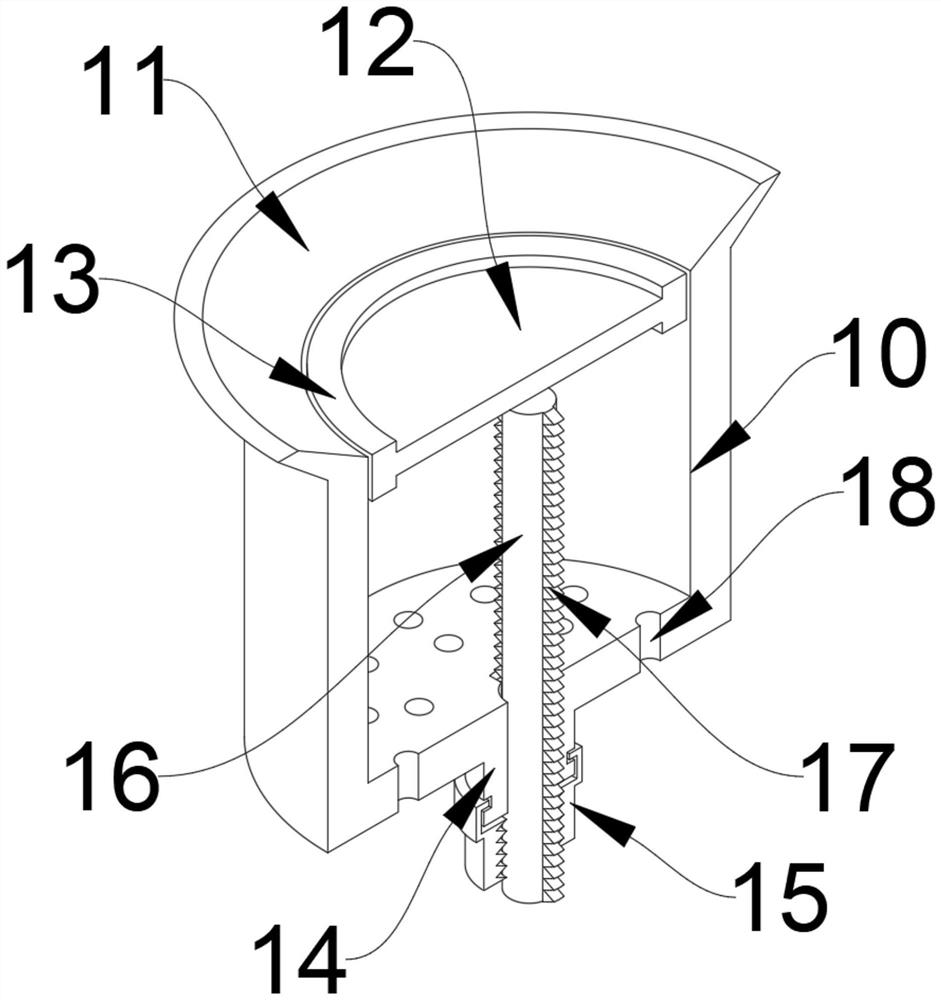

[0058] Step 2: move the first casing 19 and the second casing 20 to one end of the concrete, so that the horn gasket 11 is in contact with the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com