Frequency selective surface structure, manufacturing method thereof, antenna housing and manufacturing method thereof

A frequency-selective surface and radome technology, which is applied to antennas, antenna parts, and radiation unit covers, can solve the problems of difficult surface structure shaping and unfavorable equipment conformal design, so as to achieve good equipment conformality and improve consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

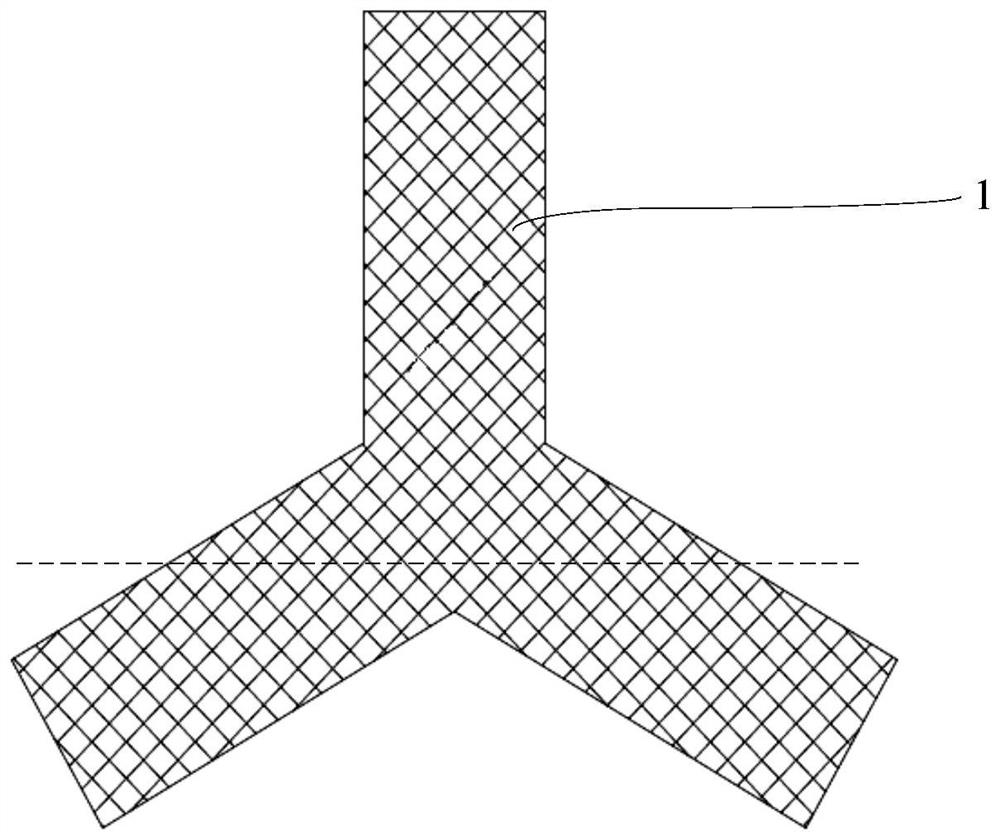

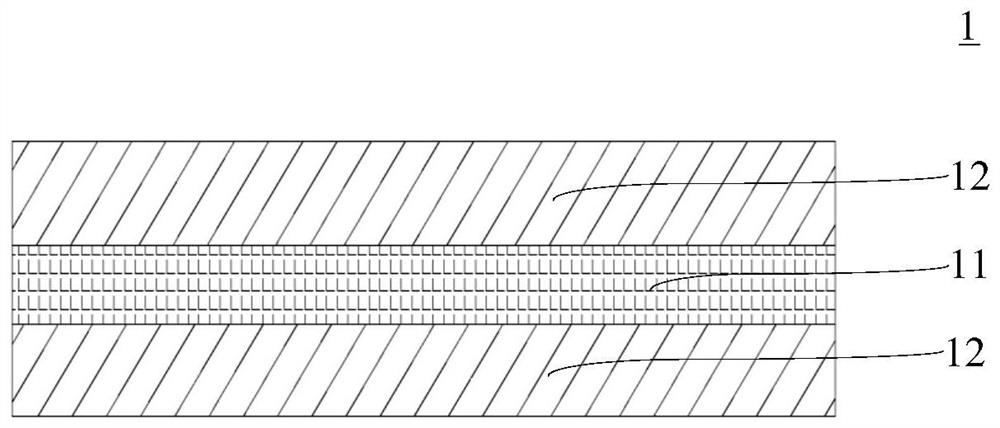

[0083] Such as Figure 7-Figure 11 As shown, the frequency selective surface structure further includes a substrate 2, the substrate 2 includes a substrate skeleton 21, and the substrate skeleton 21 and the passive resonant skeleton 11 are independently woven and formed, and the substrate skeleton 21 is woven by a non-conductive first silk thread, passive The resonant frame 11 is braided by conductive second wires. Since the substrate frame 21 is woven by the first thread, the substrate frame 21 can be woven into a shape such as a sheet or a tube, or can be woven into a shape of a product such as a radome.

[0084] Compared with the integral braiding of the substrate skeleton 21 and the passive resonant skeleton 11, the substrate skeleton 21 and the passive resonant skeleton 11 are independently braided and formed to obtain a mutually independent substrate 2 and passive resonant diaphragm 1, and only need to adjust the passive resonant membrane The position of the sheet 1 on ...

Embodiment 2

[0093] Such as Figure 12-Figure 23 As shown, the frequency selective surface structure also includes a substrate 2, the substrate 2 includes a substrate skeleton 21, and the substrate skeleton 21 is integrally woven with a plurality of passive resonant skeletons 11 to form a passive resonant hybrid skeleton 7, and the plurality of passive resonant skeletons 11 Periodically arranged in the substrate skeleton 21 . Since the passive resonant hybrid framework 7 is woven from silk threads, the passive resonant hybrid framework 7 can be woven into shapes such as sheets and tubes, and can also be woven into shapes of products such as radome. In addition, since the substrate skeleton 21 is integrally braided with the multiple passive resonant skeletons 11 , the passive resonant skeleton 11 and the substrate skeleton 21 are not easily separated, which can improve the structural stability of the frequency selective surface structure.

[0094] It can be understood that, since the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com