Composite belt, band sealer and band sealing method

A technology with seals and belts, used in chemical instruments and methods, packaging sealing/tightening, transportation and packaging, etc., can solve the problems of packaging unsuitable for distribution, appearance, negative impact of quality seal tightness, etc., to eliminate shrinkage and/or deformation, to achieve heat sealing and/or cooling, to improve the effect of sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

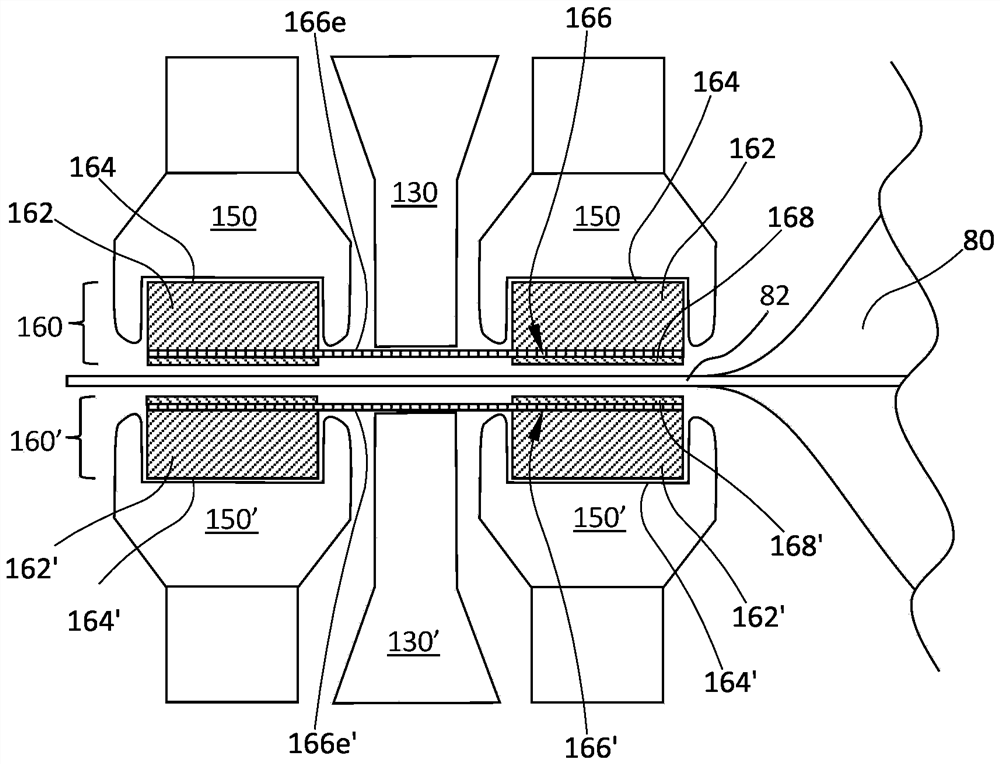

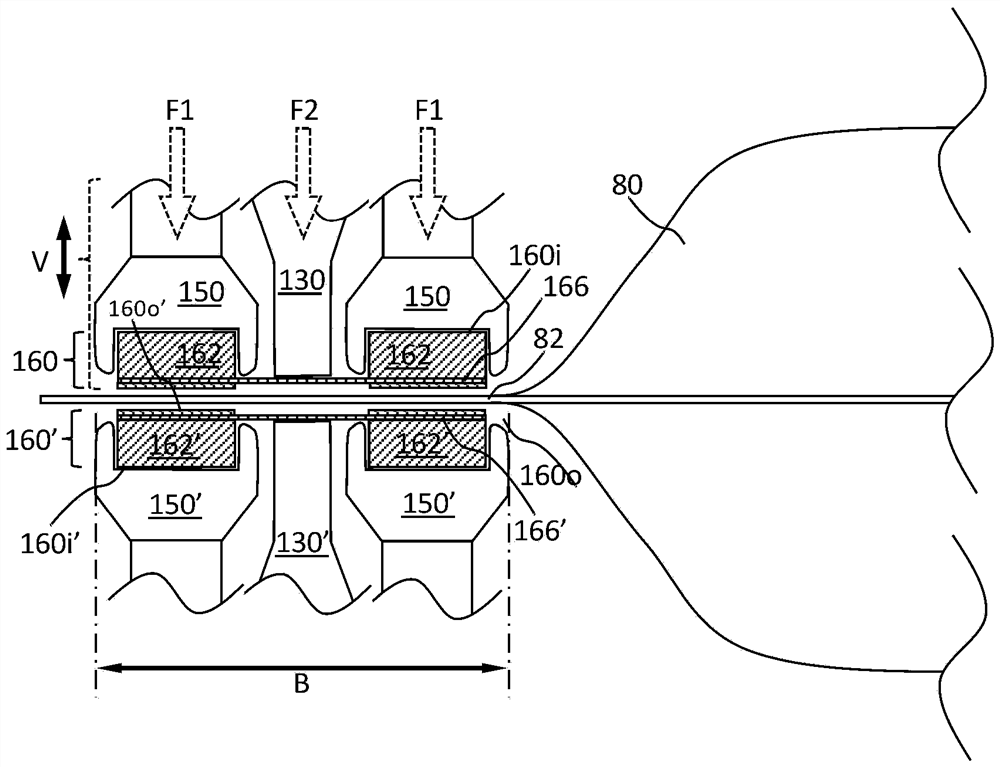

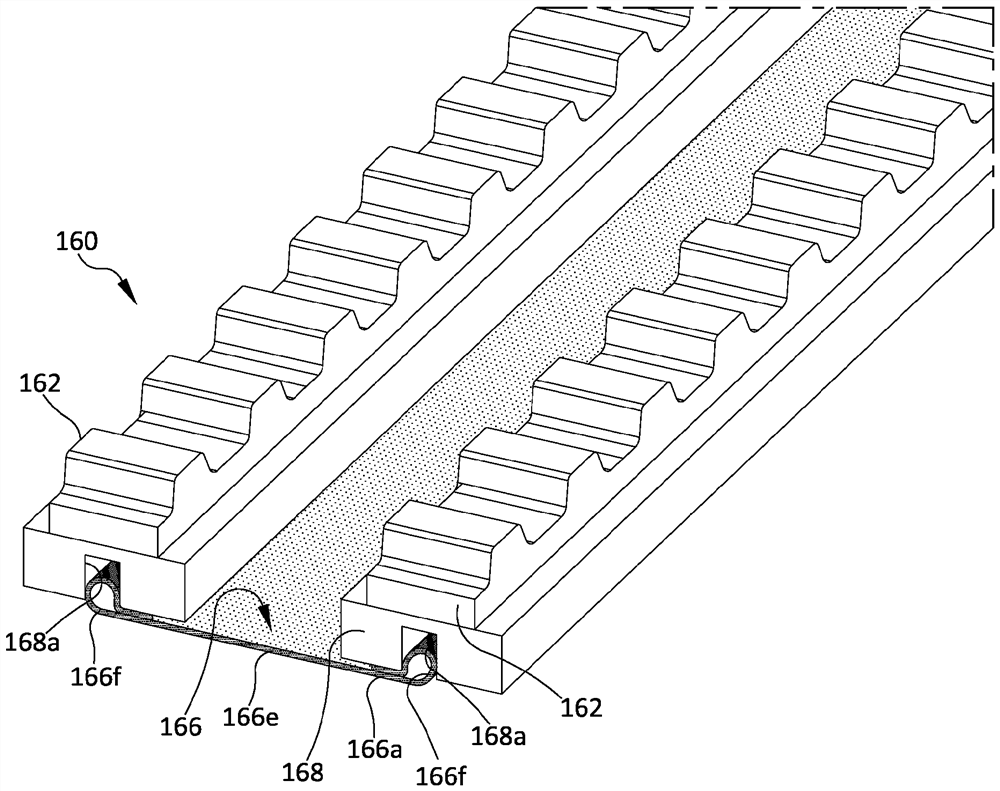

[0120] figure 1 A side view of the mechanism of the belt sealer 100 according to an embodiment of the present invention is schematically shown. Generally, the tape sealer 100 is configured to receive a package 80 containing one or more products to be packaged along the main direction of movement 60 . Package 80 includes pouch neck 82 sealed by tape sealer 100 . To this end, the package 80 is moved relative to the tape sealer 100, typically by being placed on a conveyor belt or other means of transport 71, so that the bag neck 82 of the package 80 is fed into and through the tape sealer 100 on the moving plane 70. .

[0121] Tape sealer 100 may include several components, such as one or more evacuation devices, such as evacuation rollers 120, 120', configured to apply pressure to the packaging material in bag neck 82 so as to remove air from the area of the bag neck to be sealed. Drain, remove or reduce any foreign matter. This generally improves the quality of the seal b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com